Why Hardware Teams Slow as They Scale – and How to Get the Speed Back?

Learn why growing hardware teams slow down as they scale, and how aligned workflows, parallel collaboration, and real-time design visibility restore speed and momentum.

Once hardware teams grow, they want faster design cycles. But in practice, execution often slows as the number of projects increases and product complexity grows. When teams get larger, it's harder for requirements, engineering, and procurement to stay in sync. Ultimately, teams slow as they grow.

Small teams can move quickly because their communication is direct. Engineers can realistically talk through and resolve problems in real-time, before they propagate. On the other hand, larger teams distribute more information across more tools, roles, and locations. That fragments the contextual awareness needed for good decisions, leading to slower decision-making.

In turn, most schedule slips or design rework come from late issue discovery, not from slow engineering. For example, mechanical conflicts may only surface after routing is completed. Component availability issues might only appear after BOM extraction. In any case, these delays accumulate into costly redesigns and unpredictable timelines.

True speed necessitates continuous visibility across every discipline. Teams need aligned workflows that surface risk early and allow contributors to work in parallel. Altium Teams is here to help teams regain momentum.

Why Speed Suffers as Engineering Teams Grow?

Informal coordination works well in small teams because context is inherently shared. That model breaks down once teams grow to multiple departments and geographic locations.

When conversations no longer capture every dependency, engineers try to preserve context with artefacts like spreadsheets, screenshots, exported files, and manually maintained documents. As with all manually maintained documents, each artefact is static: it shows only a moment in time, not the current state of the design. Still, teams rely on those snapshots to make decisions that affect downstream work, which introduces the risk that design fidelity will decay. That risk compounds over time.

One challenge is that fragmented tools force teams into waterfall-type workflows. Electrical teams must wait for mechanical feedback before adjusting placement. Mechanical teams have to wait for stable electrical layouts before validating enclosures. Procurement waits for BOM extraction before evaluating supply risk. Each group delays action and schedules buffers until another group completes its step.

This sequencing creates long feedback loops where insights arrive only after major milestones. Invariably, requirements changes propagate slowly, and reviewers only find issues once it's too late. Teams might attempt to compensate with extra meetings and documentation, but these additions only slow progress and increase overhead.

As projects scale to include multiple boards and disciplines, complexity exposes every weakness in ad-hoc workflows.

What Speed at Scale Looks Like?

Speed at scale depends on parallel design rather than sequential handoffs. That means ECAD, MCAD, procurement, and manufacturing teams need to act on live, dynamic design data, not static, exported artefacts. Reviewers need to comment directly on the active design so that feedback retains its full context. This eliminates misunderstandings and avoids unnecessary rework.

In practice, speed at scale looks like

- Mechanical teams evaluating enclosure fit, clearance, and height constraints against current geometry, not approximations.

- Multiple PCB designers co-authoring the same board in the same design file, not through exported handoffs.

- Procurement teams analyzing component risk early enough to influence routing and sourcing decisions.

These actions are only possible when contributors share a connected environment that aligns everyone around the same source of truth.

When updates propagate instantly and dependencies are visible, teams stop waiting for handoffs. They don’t need to compensate for missing information. Speed grows naturally when information stays synchronized and accessible.

How Agile Teams Unlock Speed at Scale?

Quick, Easy Setup

Speed at scale depends on how quickly teams can establish structure without slowing work at the outset. Many organizations delay process improvements because the setup feels disruptive. New tools often require IT involvement or long onboarding cycles that interrupt active programs. As a result, teams are inclined to improvise workflows long after they stop scaling.

Agile Teams removes that friction by building on systems teams already use to manage people. User roles, permissions, and access controls propagate familiar organizational structures that teams already know how to navigate. Engineers, reviewers, and external collaborators interact in an intuitive environment they’re already familiar with, reducing onboarding time and confusion.

Altium Agile Teams also includes workflow automation that speeds up setup. Engineers have access to flexible templates for design reviews, approvals, and lifecycle steps that teams can easily adapt with a low-code approach, without needing custom scripting. The workflows formalize repeatable tasks without imposing heavy process overhead, meaning teams can move quickly without sacrificing consistency.

Agile Teams also connect directly to existing data systems instead of replacing them. Design data, requirements, and project context are all linked, not duplicated across disconnected tools. A high level of integration maintains continuity and eliminates manual synchronization.

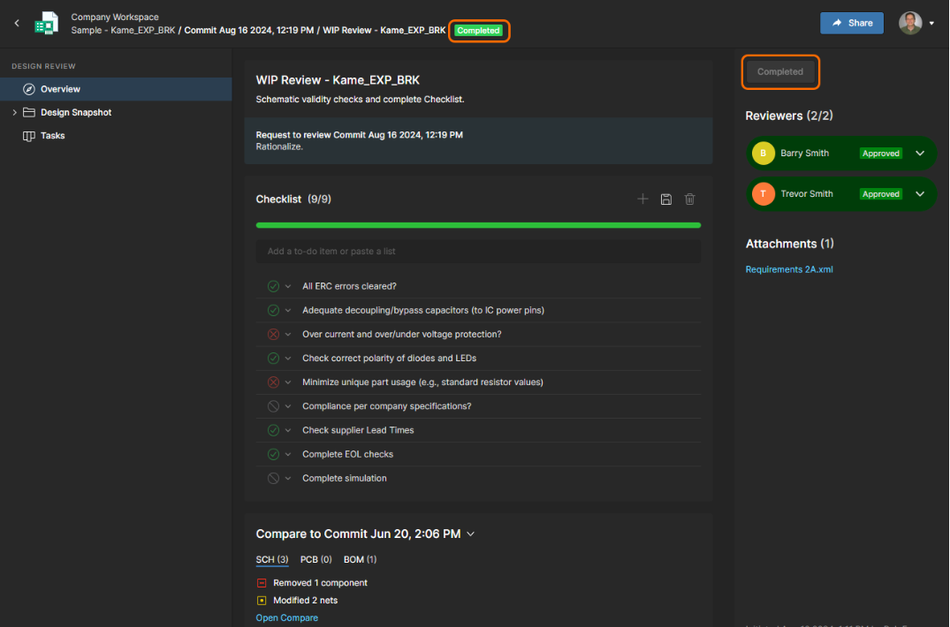

Continuous Collaboration

Agile Teams provides a shared environment where every contributor can see the latest schematics, layouts, 3D views, and BOM. Altium even offers browser-based access for lower friction for non-ECAD roles. In practice, that means mechanical engineers can review geometry without requesting exports, procurement teams can inspect component decisions without installing design tools, and manufacturing partners can evaluate intent well before release. As a result, more stakeholders contribute earlier in the cycle.

And, because updates propagate instantly, discussions stay continuous rather than episodic. Feedback can arrive while engineers are still designing the product, not after the design is already frozen. As a result, teams can resolve issues the moment they surface, rather than weeks later during a design review. Ultimately, early involvement exposes risk before it escalates and becomes cost and time-intensive to fix.

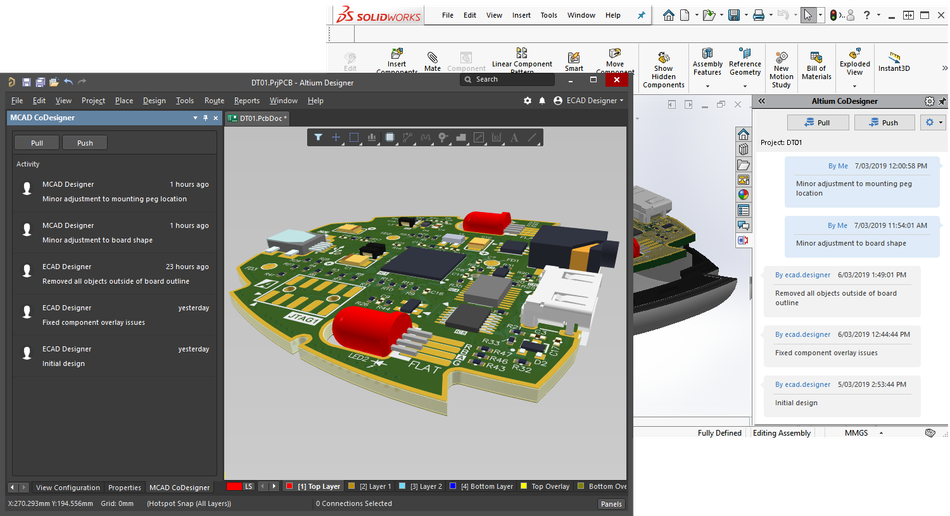

ECAD-MCAD Co-Design

A lack of electrical-mechanical coordination is a major cause of significant delays in hardware development. Where traditional workflows rely on manual file exports that break synchronization and introduce translation risk, each conversion slows iteration and erodes confidence in the data.

Agile Teams replaces this approach with a synchronized ECAD-MCAD link that keeps electrical and mechanical views aligned. PCB changes appear within the mechanical environment as native geometry, while mechanical updates are returned to ECAD without imports or conversions. As a result, both electrical and mechanical teams can operate on current data throughout the design process.

For example, mechanical partners directly examine the PCB with Altium Teams to evaluate enclosure fit, connector alignment, and height constraints. Then, they can make comments or annotations directly in the shared workspace, ensuring feedback is provided in its full context. The electrical team can respond immediately without breaking flow.

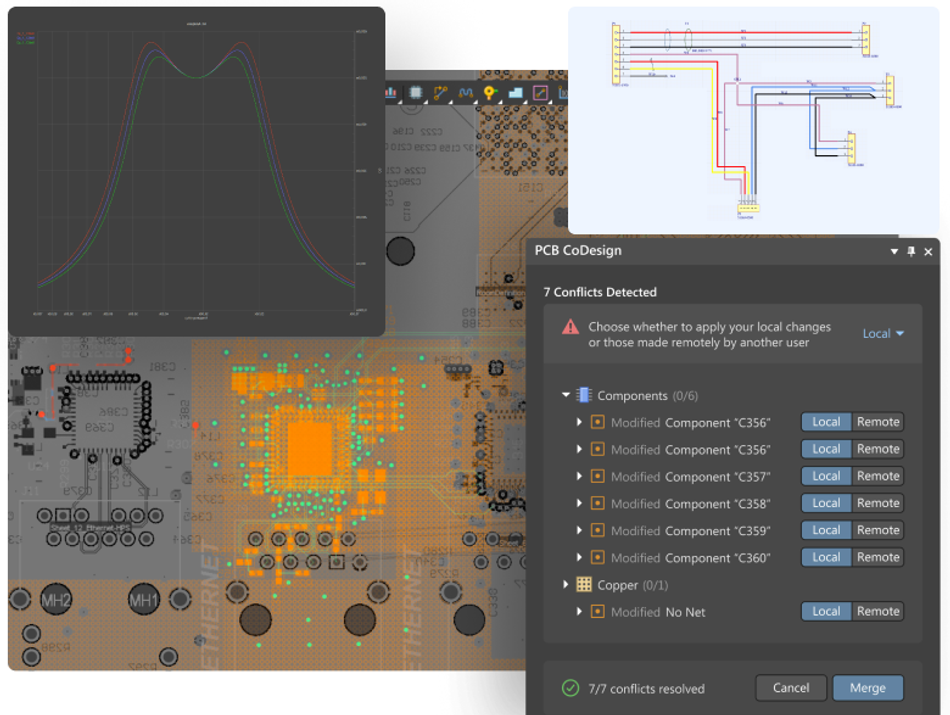

PCB Co-Authoring

Traditional PCB flows rely on sequential editing because only one designer can safely modify a board at a time. Thisslows progress and concentrates risk on individual designers. The model struggles when applied to complex layouts and aggressive schedules. No single contributor should bear that weight alone.

Agile Teams unlocks true multi-user PCB co-authoring, allowing multiple designers to work on the same board simultaneously. With that new power, teams can divide responsibility by domain or board region. Specialists can focus on areas where their expertise delivers the most value, and projects are completed sooner.

The tool also offers real-time change management through soft-locking features that prevent conflicts without blocking progress. Designers can see updates as they occur and adjust without waiting for handoffs.

Conclusion

Growing hardware teams only regain speed when contributors can share data exactly when they need it. When everyone is synchronized, alignment becomes natural, and speed at scale becomes achievable. Finally, teams can work in parallel, and errors can be caught early on, before they become significant or costly.