Swiss roll batteries, created through on-chip micro-origami, could power dust-size ubiquitous computers

A team of researchers has reviewed the state-of-the-art in ultra-compact batteries, finding challenges that lie in the path of dust-mote computing — and has proposed a clever approach to packing the power required into a tiny footprint.

Tiny batteries, smaller than a grain of salt, will be needed if the future of dust-sized computing is to be realized.

Bell’s Law, the theory put forward by Gordon Bell which states that a new class of computer is developed once, has seen computers shift from the room-filling devices of the 1960s to the desk-sized workstations of the 1970s to the compact home computers of the 1980s, laptops of the 1990s, portable digital assistants of the 2000s, and the smartphones of the 2010s.

There’s a step below smartphones, though: Ultra-compact computers, in development for use as remote sensor nodes for everything from environmental monitoring and agriculture to healthcare. The target: To launch functional devices as small as a single cubic millimeter before the end of the decade. The problem: How to power such small gadgets.

A question of power

In a “perspective” paper published by the Center for Materials at Chemnitz University of Technology, a team of researchers has studied the state-of-the-art in battery technology — and found it wanting. “Dust-sized computers will only become a new class of computing platforms,” the team predicts, “if they are available anywhere anytime, relying on energy-autonomous operation.”

While work has been done on giving such devices energy-harvesting capabilities small enough to be integrated without bulking the computing-mote out, battery power remains a challenge: Tiny batteries hold a correspondingly tiny amount of power, and approaches for packing additional capacity into large-scale batteries simply don’t work at the sub-millimeter scale.

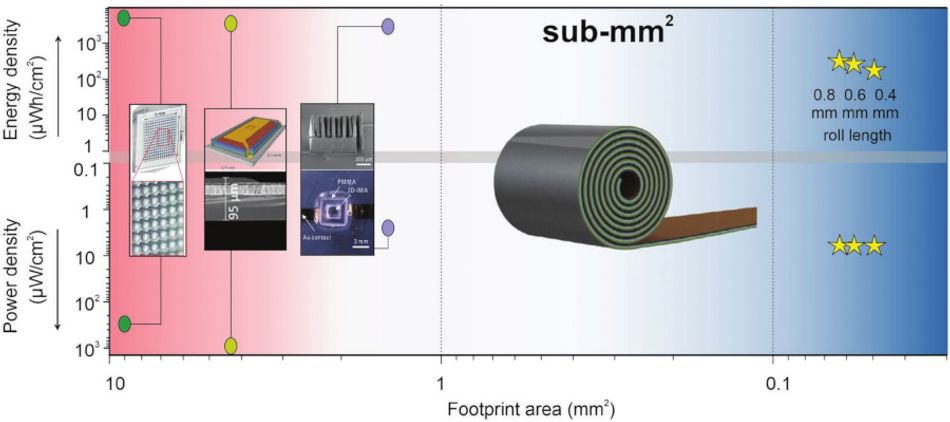

In the perspective, the team argues for two basic requirements for the successful development of a battery to be integrated into dust-sized microcomputers: A minimum energy density of 100 microwatt-hours per square centimeter (100µWh/cm2) and the ability to be monolithically integrated with the other functional electric circuits which make up the device.

“There is a desperate need to develop high-performance batteries for the millimeter and sub-millimeter size regime,” the researchers argue, “because such energy storage systems would facilitate the development of genuinely autonomous microsystems.”

The Swiss roll solution

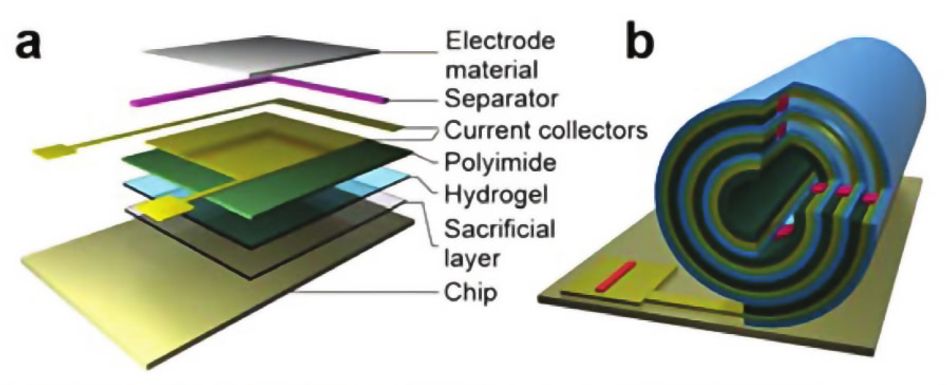

The proposed solution to the problem takes its inspiration from a tasty treat: The humble Swiss roll. Inspired by the manufacturing of large-scale cylindrical batteries, like the common 18650 lithium-ion battery, the team proposes a microbattery structure designed just like the cake: A strip of material which is rolled tightly together, forming a cylinder.

Where large-scale batteries are made separately to the device they power and simply slotted into handy holders for connection to the circuit, though, the team’s desire for monolithic integration means the micro-miniature Swiss roll battery must be made in a different way.

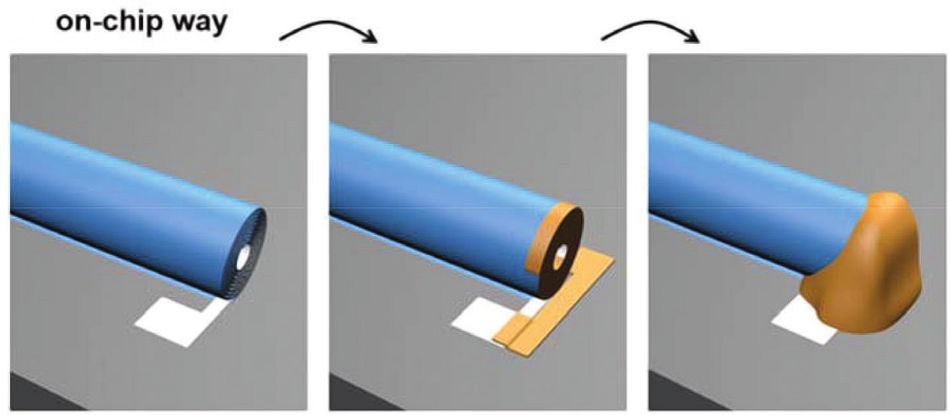

“Achieving the Swiss roll design on a chip through micro-fabrication processes is extremely difficult,” the team admits, “because winding thin and brittle layers with external forces on a chip is neither available as a mass production process nor accurate enough to achieve high yield and reproducibility.”

The proposed fix: On-chip micro-origami, in which the assembly process occurs within the device itself. Two proposed approaches are offered, both proven by previous work: The use of a “sacrificial layer” which can be etched or dissolved away to trigger the rolling process; and a polymer activation layer which offered a higher capacity limit than was previously possible.

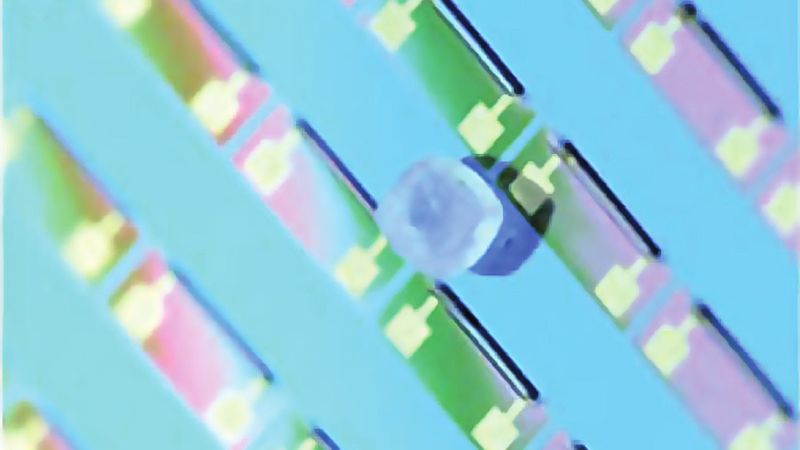

In testing the process, the team showcased functional Swiss roll batteries each smaller than a grain of table salt, and with a capacity which can be increased in a linear fashion simply by increasing the length of the rolled material. These prototype devices showed a behavior similar to full-size batteries made from the same materials, an excellent rate capability, and a capacity measured at eight times higher than its flat counterparts.

Integration

For the issue of integrating the batteries into dust-size systems, the team proposes the deployment of a technique already used to integrate photovoltaic solar energy harvesting systems: Patterning micro-electrodes onto the substrate before applying the battery layer stack and allowing everything to roll up at once.

“After the roll-up of the battery,” the team writes, "the available chip area is efficiently used to accommodate a compact and fully integrated 3D microsystem."

"The prototype batteries have already entered the deep sub-mm2 regime and offered a competitive energy density,” the researchers conclude, “demonstrating the strength of the micro-origami technology toward sub-mm2 microbatteries.”

The team’s work is available as an early access article on the Wiley Online Library, following its acceptance for publication in the journal Advanced Energy Materials.

References

Yang Li, Minshen Zhu, Vineeth Kumar Bandari, Dmitriy D. Karnaushenko, Daniil Karnaushenko, Feng Zhu, and Oliver G. Schmidt: On-Chip Batteries for Dust-Sized Computers, Advanced Energy Materials, 2022, 2103641. DOI 10.1002/aenm.202103641.

Gordon Bell: Bell’s Law for the birth and death of computer classes: A theory of the computer’s evolution. MSR-TR-2007-146.