SimpleChips: A Systems-First Approach to High-Voltage IC Design

How SimpleChips designs high-voltage silicon for systems that must perform reliably over decades?

Credit: SimpleChips

Reliability is a Design Discipline

Much of semiconductor innovation is measured by what a device can do at its limits. SimpleChips measures innovation by what a system can be trusted to do over time.

With high-voltage, electronics problems surface slowly through drift, nonlinearity, thermal behavior, or edge conditions that only appear after years in the field. In critical systems, from electrified powertrains to medical devices, these effects often outweigh peak performance. They determine whether a system remains predictable, serviceable, and safe long after it has been deployed.

SimpleChips was built around this reality. One of the company’s focuses is on high-voltage mixed-signal ICs for environments where tolerance stackups, component aging, and system-level interactions define success or failure. Its work is shaped by applications where reliability is not a specification but a requirement, and where simplifying a system adds value by making it more reliable.

That perspective is grounded in experience. It reflects decades of experience designing and manufacturing silicon for demanding environments, and a deliberate choice to work on problems few others are willing or able to address.

Reliability Understanding Starts Where Things Broke

This systems-oriented mindset is closely tied to the background of SimpleChips’ founder, CEO, and CTO, Alain R. Comeau (M. Sc.). Trained as a physicist at the University of Sherbrooke, Mr. Comeau began his career inside semiconductor fabrication facilities, working in yield engineering and process integration. Those early years left a lasting impression.

Working in fabs meant tracing problems from observed symptoms back to their root causes. It meant seeing how small variations in process or design assumptions could propagate into field failures. Mr. Comeau often describes this as “detective work,” an exercise which forces engineers to look beyond nominal operation and focus on where systems break down. Over time, this experience built a global view of semiconductor behavior across design, manufacturing, and long-term reliability.

That perspective, and the related successes attached to it, later carried into senior technical roles across multiple organizations (Mitel, EG&G, Zarlink, Microsemi), where Mr. Comeau was responsible for resolving process and yield issues from design to production. The cumulative effect of that work was a clear understanding of how tightly yield and reliability are linked, especially at the moment a product enters service.

Beyond the Design Kit: When Physics Defines the Real Limit

SimpleChips operates on the premise that design and manufacturing decisions must be evaluated together. Technology selection is guided by a disciplined assessment of risk, performance, and cost across the full lifecycle of a device. Improving yield is viewed as a direct path to improving reliability, particularly at time zero.

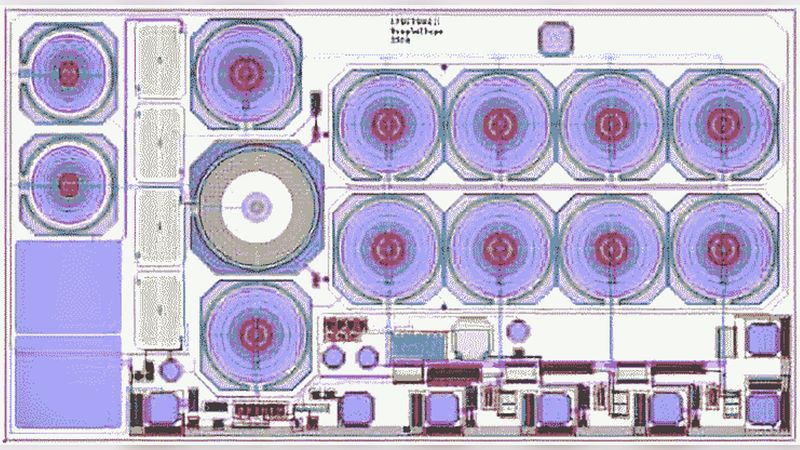

This way of thinking also directly impacts how SimpleChips approaches analog and mixed-signal designs. Many engineers work within the boundaries defined by standard process design kits. These kits provide structure and consistency while also defining what is considered feasible. SimpleChips routinely questions those boundaries when application requirements demand it.

According to Mr. Comeau, the limitations are not always a limitation of physics. It is more sometimes the result of constraints imposed by tooling and preexisting established libraries. When required, the team extends the process’ components’ libraries by developing new resistive, capacitive, or transistor structures, guided by a clear understanding of the risks involved and supported by extensive internal libraries built over time.

Simpler Architectures for Reliability

SimpleChips’ devices are designed for use in EV powertrains, industrial systems, medical equipment, and aerospace applications. These systems operate across wide voltage and temperature ranges. They are also expected to perform consistently over decades.

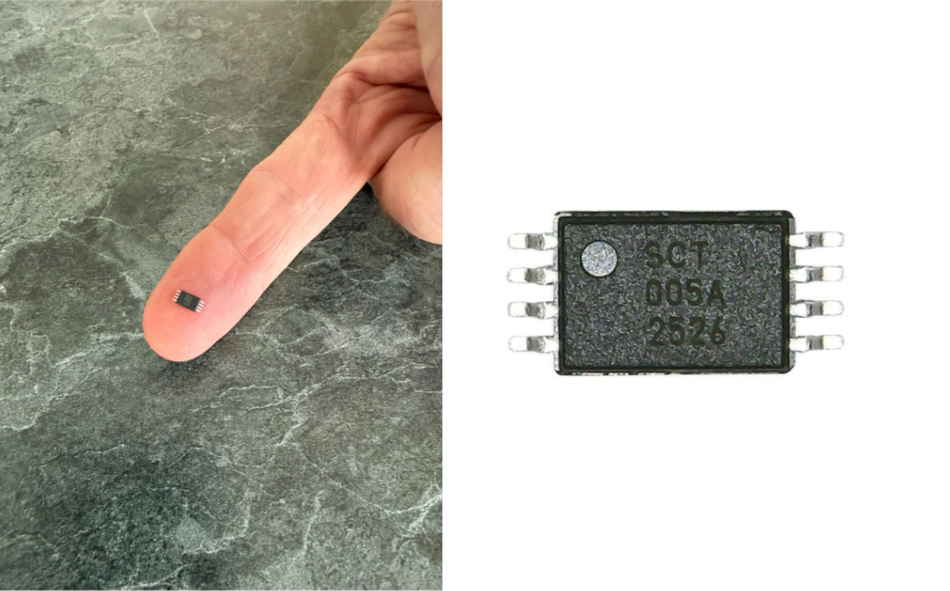

One example illustrates how this thinking translates into silicon. In developing a high-voltage monitor, SimpleChips needed a monolithic resistor network capable of maintaining an extremely good linearity of +/-0.1% from 0 to 1200 volt (or less than +/-0.60ppm/V). Mr. Comeau stated that such a unique component (p/n 18SCT005) allows designers to build accurate and compact high-voltage sensing networks without the use of bulky external components such as high-voltage resistors or strings of low-voltage resistors. He also acknowledged that while this innovation “would not win a Nobel Prize,” its value lies in its practicality.

The 18SCT005 enables simpler system architectures that would otherwise require large networks of discrete components, each introducing additional tolerances and potential failure points. By integrating this behavior into silicon, SimpleChips simplifies high-voltage sensing and improves system predictability and compactness. Engineers evaluating these devices can reference detailed performance data published on the company’s website to assess suitability for their applications.

Solving the Near-Impossible and Delivering the Essential

SimpleChips’ current product direction is rooted in a long history of custom ASIC development. Founded in 2002, the company initially focused on IP development and licensing before transitioning in 2015 to IC manufacturing and expanding operations from Canada to the United States.

Over the years, SimpleChips has built a strong reputation in enabling custom solutions for end-of-life products and legacy systems. Several of these solutions (40+) were innovative enough to warrant successful patent applications. As a result of these strong credentials and reputation, SimpleChips can now count on some of the largest U.S. system manufacturers as returning Customers.

These returning Customers demanded more than component-level expertise. They demanded system-level understanding. These “resurrected chips” simply have to be dropped into existing unchanged systems and work the very first time. Inputs, outputs, timing relationships, and environmental constraints all have to be considered. This work shaped the company’s ability to deliver digital, analog, and mixed-signal functionality within tightly constrained systems on-time.

Good Information Leads to Good Decisions

Certain patterns of information have emerged across products, and clear challenges have appeared repeatedly. As Mr. Comeau puts it, “good information leads to good decisions”. As a result of good information, better solutions have been created. Problems exist as a result of a chain of events such as “problemA = eventB and eventC.” If eventB is eliminated, then problemA can never happen. This rationale was fundamental in understanding root-causes behind some of the most complex problems SimpleChips has resolved.

SimpleChips began to formalize these recurring solutions into standard products, building a product and technology portfolio grounded in real applications. The 18SCT005 reflects this evolution. It replaces tens or hundreds of discrete resistors with a single drop-in IC, reducing assembly complexity and minimizing potential failure points. These positive impacts are equally felt at the system level. Designs become easier to validate and maintain. This improves system reliability. The value becomes what is removed from the system rather than what is added.

Engineering with Consequences

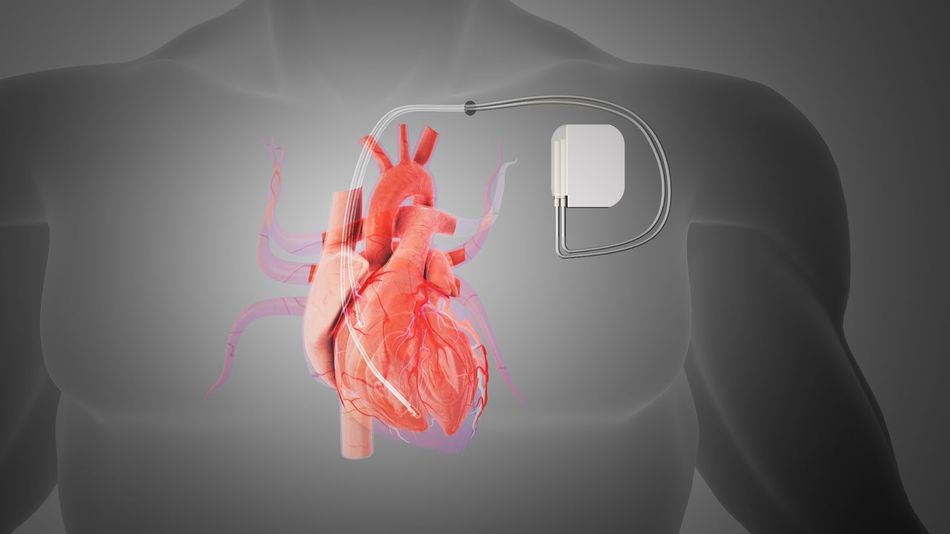

The environments where SimpleChips’ devices operate leave little room for error. Some of these devices are used in medical systems implanted in the human body. One chip has been deployed in defibrillators for a decade, where its purpose is to restart the heart, without a single failure.

Mr. Comeau has spoken candidly about the responsibility that comes with such applications. Failure in this context carries direct human consequences. This reality reinforces the company’s emphasis on rigor, accountability, and careful decision-making. Engineering choices are made with a clear understanding of where devices will be used and what is at stake.

Redefining the “Company”

SimpleChips operates a small international team of professionals. The cultural perspective, brought in by professionals coming from 8 different countries, is viewed as sources of technical breadth and innovation. Mr. Comeau often reflects on the meaning of the word “company” as meaning to “work in the company of others”. This definition considers Customers as colleagues for the purpose of a project.

Customer interaction plays a defining role in how SimpleChips operates. The company prioritizes rapid response and treats communication as an engineering input. Customers are included in feedback loops, and their insights shape both architecture and product direction. Although syntactically incorrect, SimpleChips always capitalizes the “C” in “Customers” because Customers are the most important “working-in-company-of” team member and always drive business forward.

Long-Term Engineering and Reliable Electrification

From a business standpoint, SimpleChips maintains both custom and standard product lines. This dual structure provides financial stability and reduces sensitivity to market fluctuations. Custom projects continue to shape product development, while standard products expand the company’s reach. This balance enables long-term engineering investment. It allows the company to focus on solving difficult problems without being driven by short-term cycles.

Against this backdrop of continuous investment, power management continues to drive the electronics landscape. Electrification across transportation, industries, and infrastructures (AI) are accelerating. SimpleChips operates as an enabler within this evolution, with precision, stability, and reliability as core priorities.

Mr. Comeau often speaks about positive creativity, teamwork and the responsibility that comes with building technologies for critical systems. SimpleChips’ work reflects that outlook. It is shaped by experience, informed by real applications, and guided by a clear understanding of what is at stake and what is important (root-causes) when failure is not an option.

To see detailed performance data and explore the SimpleChips product portfolio, visit simplechips.com