ROHM's Preventive Quality Assurance Approach to Zero-Defect Semiconductor Manufacturing

ROHM's "Quality First" philosophy places continuous quality assurance and attention to detail at the core of product development. The proactive approach to quality fosters reliability, drives continuous improvement, and strengthens customer trust.

Semiconductors are now the backbone of modern technology, powering everything – from electric vehicles and renewable energy systems to consumer electronics and industrial automation. As these applications become more complex and safety-critical, the tolerance for component failure is shrinking to zero.

Founded in 1958, ROHM Semiconductor develops analog and power ICs, discrete devices, SiC technologies, and more for automotive, industrial, and consumer applications. This article explores how the company puts its “Quality First” principle into practice – from the value of local quality assurance (QA) support to the shift to preventive assurance. It also highlights the advanced analysis methods used to detect even the smallest defects, while offering a broad range of state-of-the-art analysis methods to its customers.

Quality First: Building a Zero-Defect Mindset

The principle of "Quality First" is living practice at ROHM. It encompasses all process steps of the company, from design to production and service to environmental awareness. Due to the increasing number of electronic functions in various applications, the failure of a single component can trigger an avalanche effect. Therefore, the zero-defect mentality from development to mass production is more important than ever for the future success of semiconductor companies.

With its extensive range of products, from analog ICs to SiCs, ROHM is well experienced in the development and production of electronic components. Since it was founded, the principle of "Quality First" has been applied in all company processes.

Local Expertise and Preventive Quality Assurance

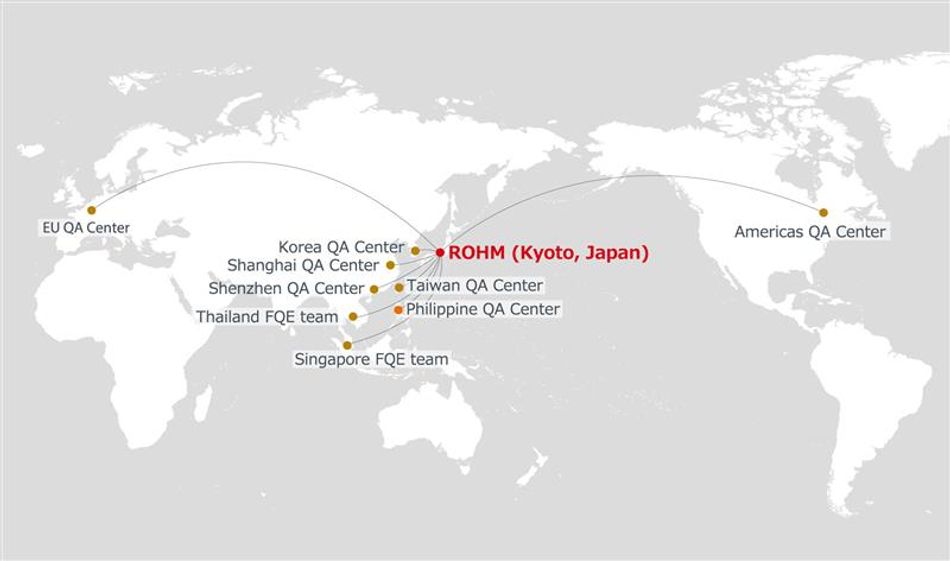

To provide customers with high-quality service through local contacts, ROHM has established its own QA and customer service laboratory in Europe, located in Willich, near Düsseldorf. The Quality Assurance Center was established more than 20 years ago “with foresight,” as Dirk Peters, Director Quality Assurance at ROHM Semiconductor Europe, describes it today. He has been working in QA at ROHM since 2007.

ROHM's local support is an extension of the company's global quality strategy to provide a high level of customer service. “The electronics industry is very fast-paced and requires quick actions. There is no time to send components around the world for examination. Additionally, different time zones, languages, and decision-making processes would slow down the output,” explains Peters.

"Therefore, it is crucial to provide our European customers with local contacts for quality and component analysis. This way, cases can be quickly assessed and analyzed. We can thus ensure a correspondingly quick response for our European customers," he adds.

"Today, the department's focus is increasingly on preventive quality assurance. We clarify in advance which quality characteristics are expected by the customer," says Peters.

Detail-Driven Quality Assurance

Various components, processes, technologies, and requirements necessitate close collaboration and detailed analyses. In quality assurance, details are crucial and must therefore be at the forefront. For Dirk Peters, this high standard of quality is a foundation to reach the goal of zero product defects.

Naturally, with ROHM's enormous product range, it is impossible for one person to understand all the details. “Therefore, many quality, product, and process experts from ROHM's Headquarters in Kyoto, Japan, work with the Quality Assurance Center in Willich to ensure a high level of detailed knowledge and support," outlines Peters.

Tools of Precision for Detecting Defects

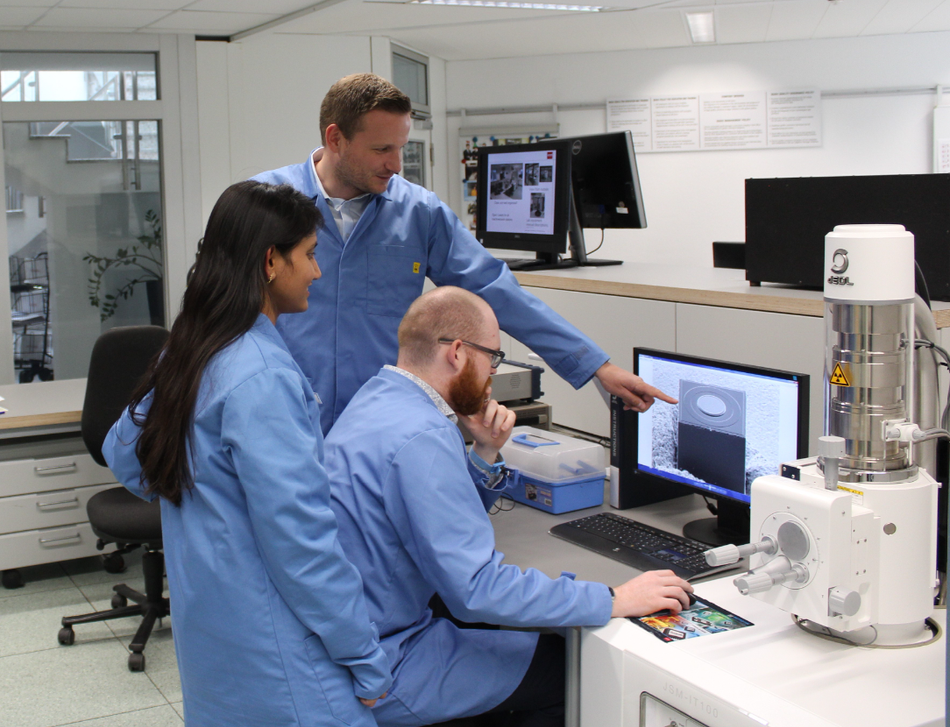

ROHM's quality assurance laboratory team uses various analysis devices, each chosen to uncover different types of defects and failure mechanisms. These methods include a range of optical, electrical, and thermal analysis tools such as: digital and analog microscopy, curve tracers (5KV/400A), computed tomography/laminography, scanning electron microscopy with EDX (energy-dispersive X-ray spectroscopy) for high-magnification examinations including elemental composition (i.e., checking for contaminants or particles).

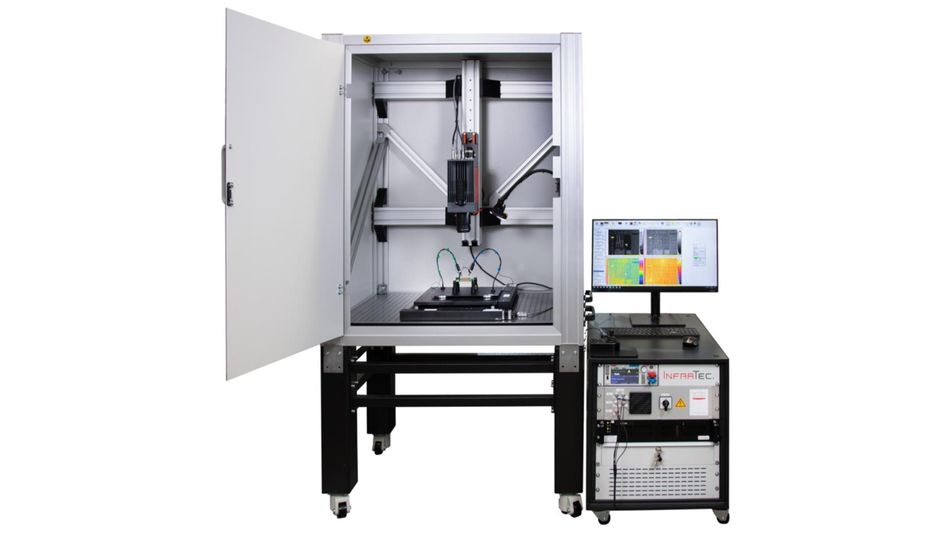

“Recently, we have expanded our analysis spectrum in Europe with a lock-in thermography device. Smallest temperature deviations, which, for example, are caused by a short circuit on a component, can be precisely detected and displayed in two dimensions,” explains Peters.

Reflecting its strong commitment to excellence, ROHM has minimized post-issue management, ensuring consistent improvement in the quality of its electronic components.

Driving Continuous Quality Improvement

Given ROHM's broad product portfolio, it is impossible to name the most common reasons for customer inquiries. There is also no “one” error pattern that occurs repeatedly. Once an error analysis has been completed, the source of the error is eliminated for all future products. “This means that a different error must have occurred during the next analysis. Otherwise, the previous work was not done properly,” says Peters.

Conclusion

As electronic systems continue to expand in complexity and criticality, QA has become a crucial factor in the success of semiconductor companies. ROHM’s local expertise, advanced analysis methods, and a preventive mindset transforms quality from a reactive task into a strategic advantage. By addressing potential issues before they reach customers, ROHM strengthens reliability and builds long-term trust in industries where even the smallest defect can have major consequences.

Looking ahead, the pursuit of zero-defect manufacturing will demand even greater precision, data-driven insights, and collaboration across the global supply chain. ROHM’s “Quality First” philosophy is a clear example of how the industry can rise to this challenge, ensuring that the components powering our cars, factories, and everyday devices deliver uncompromising performance.