Mastering Multitasking: Exploring the Distributed Processing Capabilities of TDKs Advanced Robotics

Read part 1 of 4 in our new articles series exploring TDK’s advanced robotics. This first part delves into how TDK ROS leverage multiprocessor technology to enhance precision, efficiency, and multitasking across service and industrial applications.

This is Part 1 of a four-part article series. Coming up next is: Sensing the World: How TDK’s Multi-Sensor Fusion Improves Perception in Service Robots.

Robotics are now an integral part of everything, from manufacturing and healthcare to service and automation, with the market expected to reach 189.3 billion by 2027. But as robots grow more advanced, so do the challenges—real-time processing, scalability, latency, and power efficiency all stand in the way of seamless integration. The Robot Operating System (ROS), a flexible and powerful framework designed to tackle these hurdles, is the most popular framework for developing robotics applications, offering various tools and libraries for perception, navigation, and control.

With the maturity of the unique robot culture known from anime and manga, TDK Corporation, as a Japanese electronic component manufacturer, aims to bring this world closer to reality. TDK Corporation, a leader in electronics, has introduced its innovative Robokit Lite robotics platform, compatible with ROS 1 and ROS 2 framework, which leverage a multi-processor architecture to tackle the complex challenges of modern robotics. This advanced system builds on the strengths for ROS and introduces novel capabilities that push the boundaries of robotic applications.

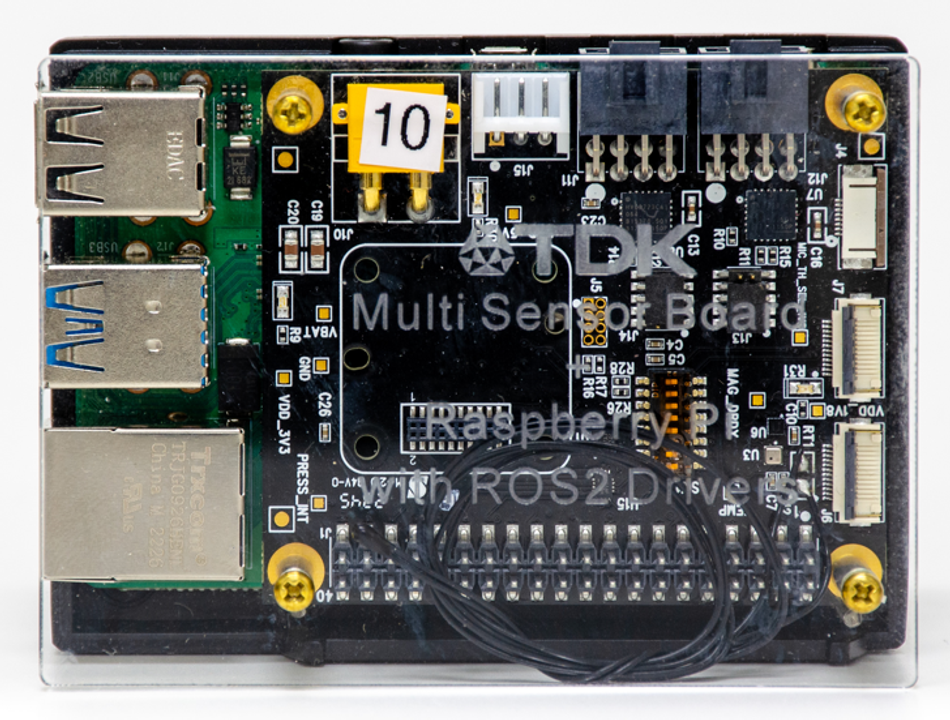

ROS is a cornerstone of robotics development. It offers a standardized platform where developers can create, share, and refine software efficiently. TDK’s implementation enhances this by integrating sensor technology into multiple processors—including Raspberry Pi—to improve multitasking and boost overall performance, stretching robotics innovation even further.

TDK Multi-Processor Architecture: Enabling Advanced Multitasking

This innovative setup allows for different functionalities by replacing three external CPUs. Specifically, the Raspberry Pi handles low-level control and sensor integration, the NVIDIA Jetson performs AI/ML tasks and decision-making, and the Qualcomm processor manages connectivity, communication, and edge computing. This configuration enables the robots to achieve optimal performance for specific tasks, facilitating intelligent decision-making and smooth interaction with the environment in real-time.

This inventive setup incorporates a combination of processors for various needs:

Raspberry Pi — The Raspberry Pi is responsible for low-level control and sensor integration. It serves as a versatile and cost-effective solution for handling basic robotic functions.

NVIDIA Jetson — The NVIDIA Jetson processor performs AI/ML tasks, computer vision, and decision-making. This allows robots to process complex algorithms and make intelligent decisions on the fly.

Qualcomm — The Qualcomm processor focuses on connectivity, communication, and edge-computing, so that robots can interact with their environment and other systems smoothly.

Additionally, TDK’s multi-sensor board RoboKit Lite integrates key product offerings such as 6-axis IMU, industrial IMU modules, capacitive barometric pressure sensor, digital I²S microphone, temp sensor, ultrasonic Time of Flight (ToF) sensors, magnetometer, and motor controller on a single PCB. This open-source board Robokit Lite comes with support for ROS 1 and ROS 2, enabling seamless integration for developing and deploying robotics applications

By distributing tasks across these specialized processors, TDK’s architecture brings us closer to the fluid, intelligent robotics —where bots don’t just follow commands but think and react in real-time.

Technical Benefits of Multi-Processor Integration

TDK’s ROS framework harnesses the power of multiple processors to unlock new levels of efficiency and responsiveness in robotics. This approach delivers several key advantages:

Reduced Latency – Parallel processing enables faster decision-making, a critical factor in time-sensitive applications where the speed of reactions can make all the difference.

Improved Throughput – The ability to handle multiple tasks simultaneously makes for smoother operation, and prevents system slowdowns.

Power Efficiency – By distributing workloads intelligently, the system minimizes energy consumption, extending the runtime of battery-powered robots.

Enhanced Sensor Data Processing – TDK’s framework integrates data from IMUs and ultrasonic sensors. Its parallel processing of IMU and barometric pressure sensor data delivers minutely accurate orientation tracking for stable and precise robotic movement.

Advanced Machine Learning Capabilities – With the NVIDIA Jetson running deep learning models for object recognition and route optimization, robots can dynamically adapt to changing environments—bringing us closer to the real-time intelligence of sci-fi robotics.,

TDK’s multi-processor integration within the ROS framework optimizes key factors like latency, throughput, power efficiency, and sensor data processing. This approach gives robots the speed, adaptability, and intelligence required for complex real-time tasks. These advancements create a foundation for the next generation of reliable and efficient robotic systems.

Comparison to Single-Processor Systems

Traditional single-processor systems struggle to compete with the increasing demands of modern robotics. They encounter bottlenecks when handling multiple concurrent tasks and tend to suffer from increased latency and higher power consumption.

TDK’s ROS framework sidesteps these limitations with its multi-processor architecture, which efficiently distributes tasks to specialized processors. Not only does this eliminate bottlenecks, but it also improves latency, throughput and energy efficiency.

The result: robots that can process sensor data, navigate environments, and execute complex tasks simultaneously. While we aren’t piloting skyscraper-sized mechs just yet, TDK’s advancements are paving the way to a future where robots feel less like automated tools and more like intelligent machines.

Utilization of TDK’s ROS in Industrial and Service Robotics

TDK’s ROS is already making an impact in both industrial and service robotic sectors, enabling smarter, faster, and more adaptable machines.

Industrial Applications — In manufacturing, real-time control, scalability, and reliability are critical. TDK’s system optimizes precision tasks and streamlines assembly lines and automation.

Service Robotics — Service robots must navigate unpredictable environments with speed and accuracy. TDK’s multi-processor setup enhances navigation algorithms and is already improving the efficiency of systems on the ground.

For manufacturers, TDK’s modular and scalable approach means reduced development time and faster product launches.

TDK’s ROS is a major step forward for robotics because it tackles the challenges of real-time processing, scalability, and efficiency. By distributing performance across multiple specialized processors, it lays a foundation for smarter, faster, and more capable systems.

Looking ahead, TDK envisions a future where robots integrate into daily life, enhancing industries and enriching the human experience. Inspired by the imaginative worlds of manga and anime—where robots are not just tools but trusted companions and problem solvers—TDK is working to make these futuristic concepts into reality. With innovations that grow the possibilities for automation, AI, and human-robot collaboration, their advancements are positioned to drive progress in everything from industrial manufacturing to personal assistance robotics.

As robotics continues to evolve, TDK continues to shape the future of intelligent automation. Whether you're a manufacturer, developer, or robotics enthusiast, TDK’s solutions offer the tools and resources you need to stay ahead of the curve. Learn more about TDK’s innovative advancements at https://www.tdk.com/en/index.html.

References

1. Advantech, “Enabling Smart Robotics with Single-Board Computing.”

2. Redding Traiger. “Robotics development platform includes sensor pack, ROS drivers” (7 Jan. 2022) . Microcontroller Tips. Accessed from https://www.microcontrollertips.com/robotics-development-platform-includes-sensor-pack-ros-drivers/

3. “TDK Announces RoboKit1 Platforms for Robotics Developers at CES 2022” (7 Jan. 2022). Robotics 24/7. Accessed from https://www.robotics247.com/article/tdk_announces_robokit1_development_platform_robotics_developers_ces_2022

4. Ibid.

5. TDK Invensense, “TDK RoboKit 1 DK.” Accessed: Feb. 25, 2025. [Online]. Available: https://invensense.tdk.com/products/robokit1-dk/#documentation.

6. TDK RoboKit1 Complete Package. Accessed from https://invensense.tdk.com/products/robokit1/

7. Redding Traiger.

8. Fouad Anwar. “Comparison of the scalability and performance of ROS1 and ROS2 in multi-robot systems” (27 Jan. 2023). Accessed from https://www.linkedin.com/pulse/comparison-scalability-performance-ros1-ros2-systems-fouad-anwar/

9. “TDK Announces RoboKit1 Platforms for Robotics Developers at CES 2022”. https://www.robotics247.com/article/tdk_announces_robokit1_development_platform_robotics_developers_ces_2022/manufacturing (January 7, 2022). Accessed from https://www.robotics247.com/article/tdk_announces_robokit1_development_platform_robotics_developers_ces_2022/manufacturing.

10. Starship. Accessed from https://www.starship.xyz/