How RFID Tags by Murata Boost System Integration

Miniature RFID tags by Murata enable seamless system integration with durable, reprogrammable identification — delivering reliable tracking, authentication & traceability beyond the limits of traditional barcodes.

For decades, barcodes have been the default method of labeling and tracking components, tools, and medical devices. They’re simple and inexpensive to implement, and can be read by any optical scanner. But, they’re no longer sufficient to meet the requirements of modern connected systems or regulated healthcare workflows.

Today’s medical devices exchange data continuously and often operate in sealed or sterile environments where visual scanning is impractical or impossible. These devices need a smarter and more reliable form of identification that can operate inside constrained spaces, integrate into electronic assemblies, and maintain data integrity.

Radio frequency identification (RFID) offers that next step. It offers automatic data capture without human intervention, readout through packaging, and the flexibility to update information after deployment. Murata offers a comprehensive suite of miniature RFID tags that combine durability, reliability, and embedded integration to help engineers replace traditional barcodes.

RFID as a System-Level Solution

Whereas barcodes are entirely passive, RFID tags are active components!

The tag itself contains an integrated circuit, a defined memory map, and a precision-matched antenna. The reader generates an electromagnetic field that powers the tag through inductive or radiative coupling and triggers a data exchange. The tag then modulates the field to return stored information to the reader. Importantly, this process works without a direct visual path and continues to function when the tag is behind plastic, film, or non-conductive barriers.

Hospitals, labs, and pharmaceutical facilities benefit from RFID tags because they reduce contact-based scanning. A reader mounted at a workstation or production bench can detect tagged items as soon as they enter the field. Staff do not need to manipulate items individually. When integrated into surgical workflows, RFID can support automated tray verification and tool authentication. In addition, every read event is part of an electronic record, leading to more reliable documentation and greater traceability.

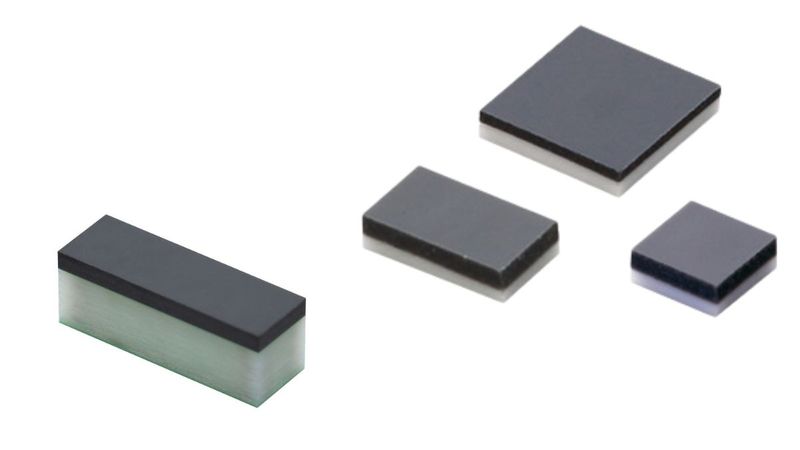

Murata’s 1.2 x 1.2 x 0.55 millimeter RFID tag package means that system engineers can embed them directly into a device’s housing or even mold them into plastic components. When the tag becomes part of the product structure, it creates a permanent, invisible identifier that’s part of the product design. The embedded configuration also protects the tag from abrasion or contamination, especially during processes such as sterilization, transport, or mechanical assembly.

What RFID Can Do That Barcodes Cannot?

Barcodes store static information that can’t change after printing, which limits their usefulness in dynamic or regulated workflows. RFID tags, on the other hand, offer reprogrammable memory regions that store useful data like device identifiers, batch numbers, expiration dates, usage counters, and maintenance history. Engineers can update these values throughout production or use cycles without modifying the physical device, making a live data store inside every tagged component.

RFID also eliminates line-of-sight constraints! Barcode-based scanners need a clean path between the label and the sensor. This becomes particularly challenging when operating in sterile or sealed environments. RFID can operate through polymer films and non-metallic housings, letting readers identify items inside enclosures without compromising containment. Facilities can therefore maintain sterility and process integrity without compromising an automated workflow.

For higher throughput operations, RFID supports multi-tag interrogation in ways that barcodes can’t. With RFID, a single reader can detect a full set of instruments or consumables at once. Surgical teams verify tray contents in seconds, or pharmaceutical operators can track vials in batches rather than scanning each unit. The system simply records every item automatically to lower labor requirements and reduce counting errors that occur during manual optical scanning.

Finally, RFID offers major durability advantages! Barcodes tend to degrade under abrasion, chemical exposure, or thermal cycling, and the resulting surface wear can render the label unusable. In contrast, Murata’s RFID tags operate independently of surface conditions because the antenna and memory reside inside a sealed microelectronic package. Tags can maintain communication through mechanical shock or temperature fluctuations.

Enabling Authentication and Traceability

Beyond tracking, RFID brings authentication into the device ecosystem. In a surgical setup, for example, the base unit of an electrosurgical tool can use RFID to verify that a disposable tip or accessory is genuine before allowing operation. The system can check the stored identifier against an authorized list and enable operation only when the accessory matches the expected profile. This type of workflow effectively prevents the use of dangerous, unvalidated, or counterfeit components.

Murata’s RFID tags can store unique identifiers that support anti-counterfeit workflows. Manufacturers can simply program these identifiers during production, and the values become a permanent form of authenticity. Even if a counterfeit accessory mimics the mechanical design of a genuine part, the RFID system rejects the device because the identifier does not match the trusted database.

The company’s tags also offer a secure memory structure that helps manufacturers program unique identifiers at production while still maintaining updatability throughout its lifetime. Facilities can update relevant fields during packaging, distribution, or deployment, and each update becomes part of the device’s digital history. In that way, RFID systems can maintain full transparency and a consistent chain of verification from production through end-of-life.

Built on Murata’s RF Expertise

Reliable RFID performance depends on predictable antenna behavior, effective coupling with the reader, and stable operation in the presence of nearby materials. With extensive RF engineering experience, Murata guarantees consistent RFID communication in environments where conventional tags show degraded performance.

Engineers using Murata’s tags can rely on the company’s optimized antenna structure, which is already built into the device to minimize design overhead. There’s no need for custom antenna layouts or iterative tuning cycles. The tag just performs reliably from the start. The result is less engineering overhead for system integrators who need predictable read ranges in complex environments.

Conclusion

Murata’s RFID solutions offer flexibility, durability, and intelligence that barcodes can’t match. Whether for product authentication or embedded device identification, these tags provide reliability backed by decades of Murata’s RF expertise.

Explore how Murata’s RFID tags can support your next design: murata.com/products/rfid