How AI is Accelerating Advancements in Electronics Manufacturing

Artificial intelligence (AI) is providing an opportunity for the electronics industry to accelerate design and development and speed up part sourcing.

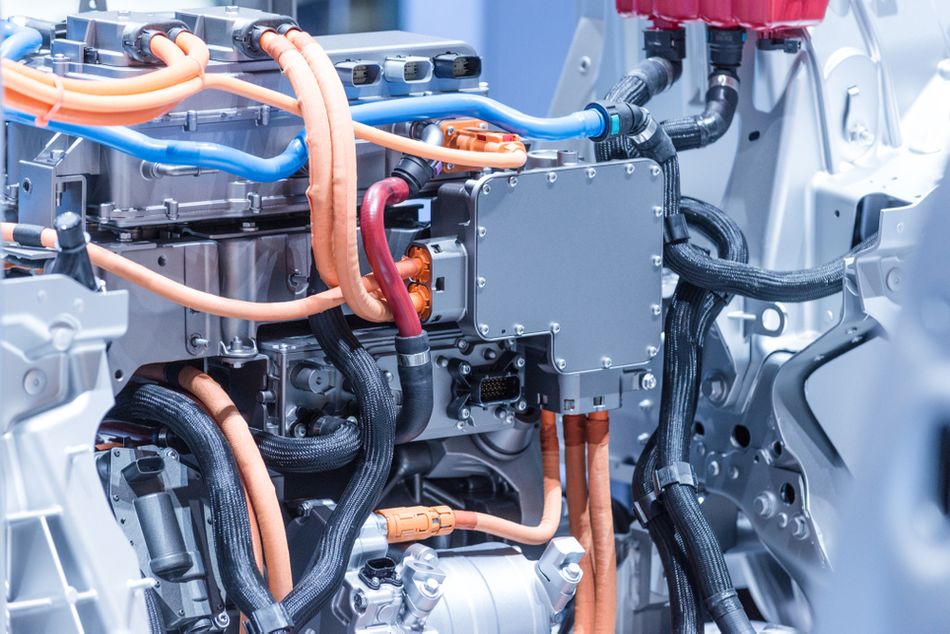

The electronics industry has some incredibly complex manufacturing practices and supply chains. Electronic technology evolves at a rapid pace, and products often contain dozens of components sourced from all over the world. Take the Apple iPhone 15, for example. The pocket-size device has a frame made by Chinese company Foxconn, a display made by Korean tech giant Samsung, and communications chips from U.S. companies Qualcomm and Broadcom. That’s a lot of technology and a lot of logistics.

But a complex supply chain is just the tip of the iceberg. Electronics manufacturers are faced with many diverse challenges such as expanding into new markets, ensuring quality products while dealing with increasing part complexity, reacting to supply chain volatility and resiliency, and dealing with rising concerns over the carbon footprint of electronics throughout their life cycle. Safety issues and smaller forms add further challenges.

Current trends in electronics address some of these issues but exacerbate others. Developments in material science are resulting in advanced electronics materials that are lighter and more energy-efficient, helping reduce the carbon footprint of electronic products while heightening their performance. 2024 may even see a rise in the use of biodegradable electronics. Elsewhere, electronics 3D printing continues to show promise in terms of agile manufacturing that eases pressure on global supply chains by localising production, as well as specific applications like 3D printed flexible PCBs. Yet these new developments bring added technological complexity and create new challenges.

So where does integration of artificial intelligence (AI) come into play? AI is expected to be a major electronics industry trend in 2024 — in terms of production, supply chains, and features of products themselves. As the technology continues to evolve at a rapid pace, engineers and product designers have the opportunity to harness AI for faster and more effective ideation, rapid prototyping, and shorter time-to-market, while suppliers and OEMs can deploy AI for tasks like predictive maintenance and defect detection. AI can also be deployed in procurement processes for smart supply chain management, using big data to make better forecasting and buying decisions. Finally, consumers are beginning to demand improved AI features in products. For example, the next iPhone is expected to provide a revamp of the AI capabilities of its “Siri” digital assistant.

This article discusses how AI is accelerating advancements in electronics manufacturing for vendors, suppliers, distributors, and beyond. It focuses on two key areas: expedited product development and smart procurement for improved part sourcing.

Accelerating Product Design and Development

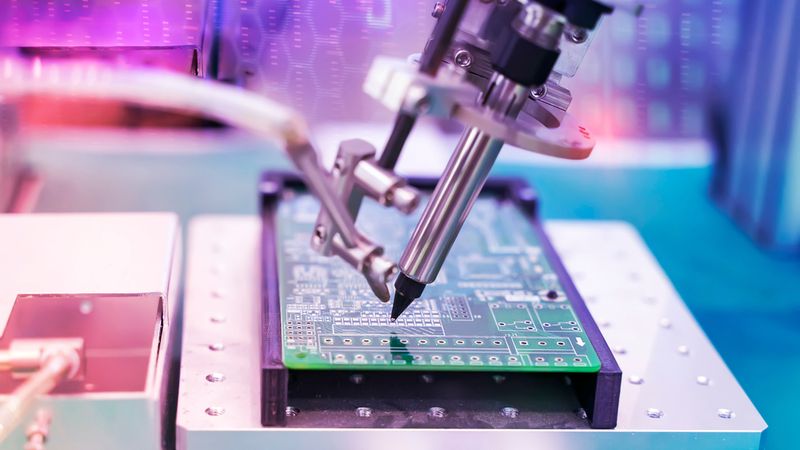

One of the most exciting potential uses of artificial intelligence in the electronics industry is the acceleration of product design and development. Engineers and product designers can use AI tools to expedite idea generation and iteration, visualize and develop those ideas, automatically generate Design for Manufacturability (DfM) feedback, initiate and oversee rapid prototyping, and ultimately reduce the time-to-market for cutting-edge products.

AI can be implemented at the earliest stages of product development. For example, during market research, companies can use AI tools like Appen and Speak to turn data into consumer insights, helping them identify market opportunities. Some of the biggest limitations on this kind of AI use is limited or noisy data, but the electronics industry — particularly consumer electronics — can potentially provide vast datasets due to the large number of end-users.

Even greater opportunities arise during the ideation stage. Generative AI tools, including large language model (LLM) chatbots like ChatGPT and text-to-image systems like Midjourney, can assist product designers with concepts and early designs. For example, users could submit a prompt such as “five new plug-and-play USB devices targeted at senior citizens” to an LLM chatbot. Ideas can then be developed organically or with further dialogue with the chatbot.

Text-to-image generation tools provide opportunities for ideation, particularly in areas of electronics where innovative or unusual design can be a major selling point. While a tool like Midjourney may be unlikely to stumble upon an iconic new design like the Sony Walkman or iPod scroll wheel, it could be prompted to ideate new designs for a product such as a pair of headphones. Generative AI tools are helpful for product designers, as they encourage outside-the-box thinking and challenge preconceptions that humans may have trouble overcoming without assistance.

Generative design tools within established CAD applications like Solidworks Autodesk Fusion 360 and Siemens NX are another way to automate part design and allow engineers to define specific parameters and manufacturing requirements that would not be possible with simple text-to-image generation. This use of AI allows for the solving of specific engineering challenges — reducing the mass of a digital camera body by a set percentage, for example.

Further along the product development cycle, machine learning is steadily being incorporated into design for manufacturability (DfM) analysis. DfM allows engineers to validate the manufacturability of designs before prototyping, and is typically based on manually written rules (machine envelopes, material behavior, etc.). However, AI is opening up opportunities for more efficient and automated DfM analysis. For instance, researchers have successfully used supervised machine learning during semiconductor fabrication to more accurately identify errors.

Smart Procurement for Supply Chain Management

One of the most promising applications of artificial intelligence in the electronics industry is smart procurement: using AI to automate and streamline procurement processes and tackle supply chain challenges using big data. As discussed in the introduction to this article, electronics supply chains can be complex and volatile — a fact made evident by the industry-damaging global chip shortage of 2020–2023 — and buyers need all the tools at their disposal to deal with such challenges.

As discussed in the Xometry white paper The Ultimate Guide to the Use of Artificial Intelligence for Supply Chain Optimization, smart procurement can be defined as the use of “advanced analytics, visualization, robotic process automation (RPA), big data, and artificial intelligence” within the procurement department in order to improve performance. The scope of AI usage can include machine learning, natural language processing, and other systems.

So what can AI achieve in electronics procurement? Ultimately, nobody is proposing that all part sourcing be left to computers. Rather, AI can be used to perform specific tasks, analyzing massive datasets to reduce risk, streamlining processes, and providing clearer information that leads to faster and more cost-efficient procurement. Would AI have been able to predict the pandemic-related chip shortage? Perhaps not, but datasets can include a very broad range of data points to help identify both risks and revenue opportunities such as new markets and suppliers.

Specific examples of AI usage in procurement include the use of machine learning algorithms for processes like vendor matching — connecting supplier data to a vendor hierarchy — and cloud-powered instant quotations based on technical drawings that significantly shorten the pricing process. While speeding up such tasks may not seem like a radical application of AI, it is precisely the kind of area of supply chain management that can benefit from additional computing power, leaving humans to focus on high-level decision making. But AI algorithms deployed in such a way can have radical results — helping detect anomalies that could be missed using traditional methods, potentially helping to detect instances of fraud, for example.

While electronics procurement departments may be hesitant to overhaul their systems in favor of AI-driven smart procurement, change is certainly on the horizon. According to a Deloitte survey of chief procurement officers, high-performing officers are “18x more likely to have fully deployed AI/cognitive capabilities” in their workflow.

Conclusion

Artificial intelligence is changing the electronics industry in many ways. As a consumer, expect to see greater advancements in AI-powered products like IoT devices, smart home components, and smartphone apps. However, some of the most impactful changes will be taking place behind the scenes in the form of AI-assisted product development and buying strategies, allowing for even faster emergence of new and exciting technologies.