Flexible and Printed Electronics: Breakthroughs, Applications, and Challenges

Step into the cutting-edge technologies and future trends of flexible and printed electronics.

Flexible and printed electronics have significantly evolved in the last few decades, bringing several advantages for multiple industries, such as biomedical, automotive, satellites, and more.

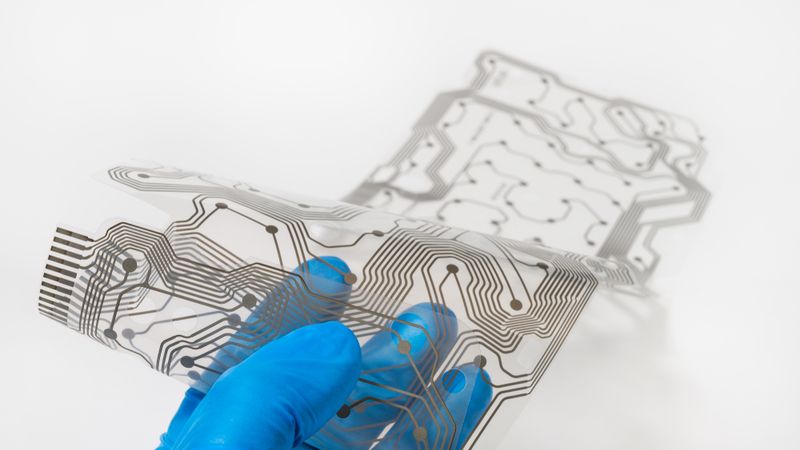

Flexible electronics refers to a class of lightweight printed circuit boards that can be bent, rolled, or even folded without losing functionality. It covers electronic components and devices built on stretchable substrates that can be used in applications such as displays and sensors.

Printed electronics are manufactured by processing combinations of thin layers of functional material (ink) on a low-cost substrate that can be recycled or degraded naturally. This technology has the potential to lead the electronics industry toward e-waste minimization.

Considering the benefits of flexible and printed electronics for different industries, this article explores the current state of these technologies, recent breakthroughs and trends that we can expect to reach the market in the next few years.

Flexible and Printed Electronics Applications

Flexible and printed electronics production is based on industrial techniques such as flexography or screen printing. Printed electronics already enable the production of flexible keyboards, adaptive antennas, interactive books and posters, electronic skin patches, sensors, and more. The printed electronics field has made significant advances, particularly in Radio Frequency Identification (RFID) and sensing labels, contributing to a new solution in smart packaging.

The growth of IoT applications has increased the demand for lightweight and cost-effective technologies that can securely detect, store, and transmit information. Flexible electronics is an ideal solution to fill this gap and satisfy the requirements of these applications.

Latest cutting-edge technology in Flexible and Printed Electronics

Regarding advances in flexible and printed electronics in recent years, printing processes and materials have made significant progress.

Processes

In terms of printing processes, various methods have been used for printed electronics. However, two techniques stand out and have been the main approaches to printing: contact printing and non-contact printing.

In contact-based printing technology, however, structures printed with ink are brought into physical contact with the substrate. Gravure printing, gravure offset, flexography, and roll-to-roll (R2R) printing compose contact printing technologies. Significant progress has occurred in some contact techniques, such as R2R.

In non-contact printing, the solution is dispensed through openings, and structures are defined by moving the substrate support in a pre-programmed pattern. The main non-contact printing techniques include screen printing, slot coating, and inkjet printing. These techniques have received more attention because they are simple, affordable, fast, and adaptable to manufacturing.

Materials

The most promising alternative materials for flexible electronics are organic materials and oxides. Particularly, combining organic and inorganic materials with printing technologies enables the creation of thin, lightweight, environmentally friendly, and economical electronic systems.

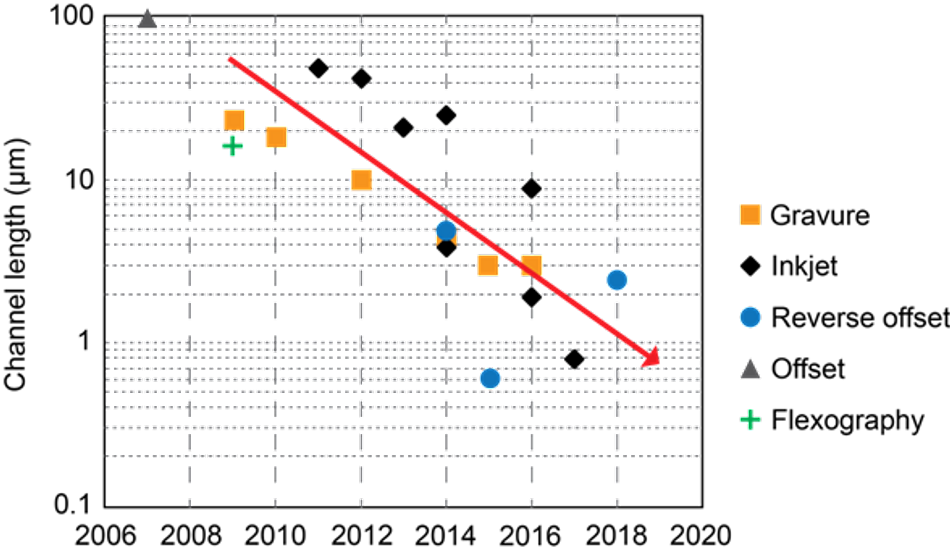

New inks also are needed to advance printed electronics, making it possible to achieve higher electron mobility thin-film transistors (TFTs) with greater uniformity and reliability. TFTs require downscaled electrodes to achieve a high enough switching frequency for wireless communication applications. The downsizing of TFTs is a beneficial factor in flexible and printed electronics applications.

Another aspect is the improved sensitivity of printed sensors achieved through downscaling, such as using interdigitated electrodes. These are manufactured by combining two separately addressable electrode arrays.

Trends and challenges

Despite the significant advances made by oxide-based devices and organic materials, research is still needed to improve the electrical characteristics and increase electron mobility and threshold voltage stability. In addition, reducing the bias and instability of the light voltage are points to be improved to increase the quality of flexible electronic systems.

Applications such as organic light-emitting diodes (OLEDs) and organic photovoltaic diodes (OPV) have already reached a certain level of maturity. However, stability is still a challenge to overcome using them for printing on flexible substrates. Flexible OLEDs have shown promise for display and lighting applications in smartphones. However, there still are issues regarding the materials used, such as low-intensity blue-light fluorescent materials, because high-intensity materials have a reduced lifetime. TFT metal oxide drives OLED displays, but election mobility and photoelectric stability improvements are needed. A possible solution could be doped oxide TFTs. One of the challenges in TFTs is the instability of gate bias voltage and low electron mobility, affecting product efficiency. Silver or other metal-based inks look promising for improving the mobility of these transistors.

Regarding OPVs, it is a proven, stable technology that can operate for tens of thousands of solar hours if protected from damaging oxygen and humidity. It has good stability and low printing cost. However, one of the problems with the technology is that it has a lower efficiency than conventional solar modules. Therefore, it requires further development for OPVs to achieve commercial maturity to be widely used.

IoT can also benefit significantly from flexible, printed electronics. However, to get the most out of it, new energy storage systems are necessary to meet the demand for such applications. Therefore, improved inks and substrates are essential for these technologies' scalability.

What we should expect for the next 5 years

Roll-to-roll (R2R) has the high potential to enable the development of inexpensive, wearable, large-area electronic devices in the coming years. Once the desired improvements are achieved, this technology will be a promising trend for the coming years.

Similar to R2R, 3D printing of flexible electronic systems is also a trend for the coming years. 3D-printed electronics allow complete circuits to be integrated into an object. It will enable the production of wearable electronics, bioelectronics, and personalized healthcare systems. In addition, flexible electronics can integrate electronics and technology to create interactive and functional clothing or accessories by immersing textile electronics.

Flexible and printed electronics are not only prominent in the areas of technology but also in the field of healthcare. Flexible electronic medical devices for remote patient monitoring can be more convenient and comfortable. Tracking vital biometric parameters such as heart rate, movement, and temperature would facilitate digital health.

Following the trends, the use of flexible and printed electronics in modernizing automotive products is present in manufacturers' innovation. Examples include thin-film heaters, flexible backlighting, and capacitive touch surfaces. In addition, it helps improve connection to telecommunications infrastructure through transparent antennas, which is crucial to the concept of the connected car.

Finally, flexible electronics support Industry 4.0. The main focus is on increasingly adopted factory sensors to monitor products and production processes. 3D electronics help sensors adapt to the existing production infrastructure and reduce costs. Vibration and temperature sensors can be fitted to mechanical equipment to observe it and help with predictive maintenance. Asset tracking and leak detection are also applications for flexible electronics in the industrial environment.

Conclusion

Flexible and printed electronics have made products smaller, lighter, and more malleable. In addition, this technology has opened doors to new form factors and different applications, providing biodegradable and recyclable solutions and a solution to electronic waste. The technology is already achieving high quality on an industrial level, with applications in multiple areas.

Among the breakthroughs, more efficient printing processes and materials, such as non-contact and contact printing, have been developed. Regarding trends, the utilization of organic light-emitting diodes (OLEDs), organic photovoltaic power (OPV), and printed TFTs have been a trend. However, some challenges such as instabilities, low efficiencies and improved substrates need to be overcome to solidify these technologies. Despite the challenges, flexible and printed electronics have the potential to significantly contribute to digital health, modernize automotive products, Industry 4.0 and IoT.

References

- https://link.springer.com/chapter/10.1007/978-3-031-21610-7_3

- https://ati.ec.europa.eu/sites/default/files/2021-04/Flexible%20and%20printed%20electronics.pdf

- https://escholarship.org/uc/item/4xz53786

- https://www.mdpi.com/2504-4494/5/3/89

- G. Grau, V. Subramanian, Fully high-speed gravure printed, low-variability, high-performance organic polymer transistors with sub-5 V operation. Adv. Electron. Mater. 2(4), 1500328 (2016). https://doi.org/10.1002/aelm.201500328

- https://onlinelibrary.wiley.com/doi/full/10.1002/advs.201801445

- https://www.idtechex.com/en/research-article/what-does-2023-hold-for-printed-flexible-electronics/28172

- https://www.tapecon.com/blog/how-printed-flexible-electronics-are-shaping-the-future

- https://www.idtechex.com/en/research-article/3d-electronics-an-alternative-to-pcbs/21456