Enhancing Assembly Efficiency with OMRONs XW4M/XW4N Push-In Terminal Block PCB Connectors

OMRONs XW4M/XW4N push-in terminal block PCB connectors are designed to simplify wiring, inspection, and maintenance while supporting consistent performance in industrial systems.

AI-Generated Image by Google Gemini 3 Pro

In industrial manufacturing, the pressure on assembly and maintenance teams continues to rise with the introduction of every new product. Production lines are expected to handle higher product variety and fast changeovers while sticking to strict delivery times, often with fewer experienced operators. In such a situation, even small inefficiencies in wiring or connector handling may add up to lost time, operator fatigue, and rework.

Operators interact with connectors on a regular basis during assembly, inspection, installation, and maintenance. Yet, a lot of conventional connectors in the market require excessive insertion force, awkward tool usage, repeated retightening steps, and lack clear pin markings. OMRON addresses these challenges with its XW4M/XW4N Series Push-in Terminal Block PCB Connectors, which are designed with ease of use, predictable handling, and workflow efficiency as a core focus.

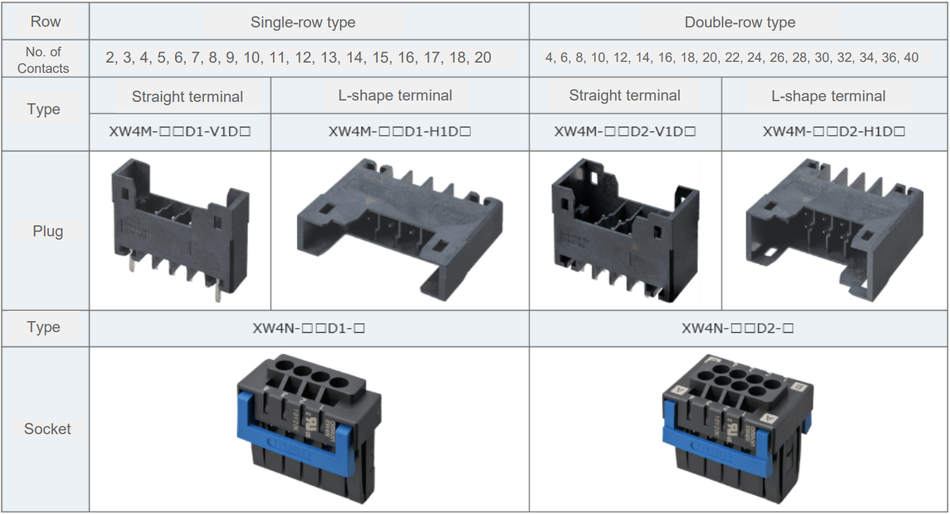

OMRON’s XW4M/XW4N Lineup Overview

OMRON’s XW4M/XW4N family of Push-in Terminal Block PCB Connectors is a flexible platform rather than a one-size-fits-all solution. It makes it easy for design, production and maintenance teams to standardize on a signal connector concept while still accommodating different layout and wiring requirements.

The lineup consists of two complementary products:

- The XW4M series, which serves as the plug side

- The XW4N series, which serves as the socket side

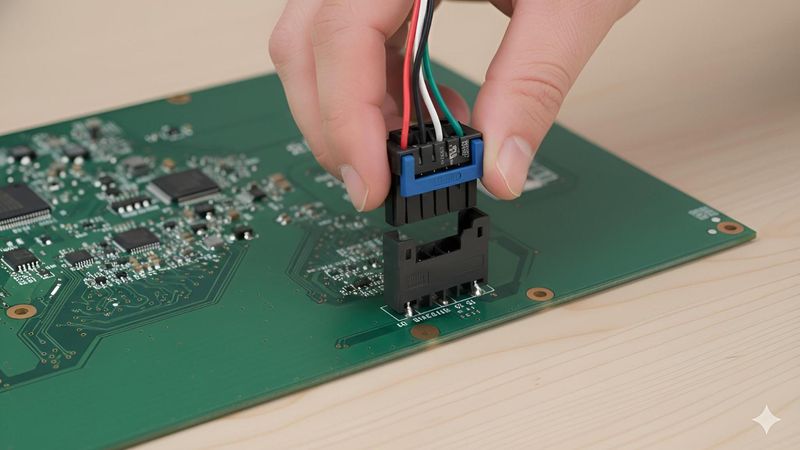

Together, they form a connector system that supports repeated mating and unmating cycles without compromising on handling comfort or electrical stability.

The connectors support different signal densities and enclosure constraints. The products are available in both single-row and double-row variants, covering a range of contact counts from low-pole connections for simple I/O to high-density interfaces for complex control/signal routing. With this capability, engineers can scale designs without having to switch connector families, which simplifies part selection and inventory handling.

Both straight and right-angled terminal options are available for increased mechanical flexibility. Designers can choose the orientation that fits their board layout and cable routing strategy.

The XW4M/XW4N range also includes accessories such as coding keys that prevent incorrect mating, short bars for circuit bridging, and dedicated release tools. These additions enhance assembly safety, make system configurations clear, and enable easy testing for multi-connector or high-mix environments.

Core Features

OMRON’s XW4M/XW4N series stands out by focusing on how the connectors are actually used, instead of just the specifications. Several design features work together to reduce effort and limit errors.

Dual-Spring Structure for Low Effort and High Reliability

The uniquely designed dual-spring internal structure for the connectors drastically reduces the force required for insertion or removal when handling the connectors. Despite the ease of use it offers, the connector delivers consistent electrical contact that does not depend on the operator’s strength or tightening technique.

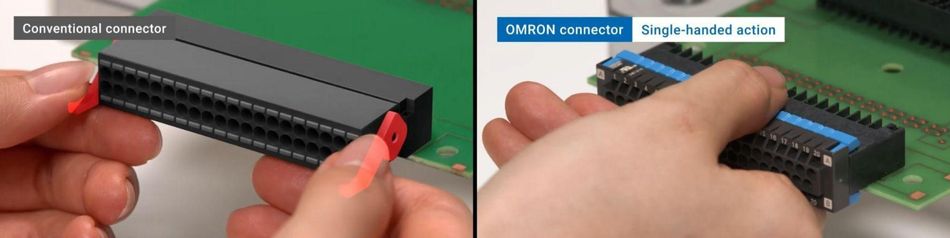

One-Hand Operation for Confined or Busy Workspaces

XW4M/XW4N connectors come with a release lever that is positioned such that insertion and removal can be performed with just one hand. This offers a practical advantage where technicians may be working in narrow spaces or supporting other elements with the other hand.

Hands-Free Wiring Support

Wiring often needs more precision than force. The XW4M/XW4N connectors feature release holes that can hold and release a screwdriver in place, keeping terminals open while the technician inserts the wire. This hands-free approach is especially useful when dealing with ferrules, bundled wires, or tight bend radii.

Using the same release holes, technicians can access the connector points for performing continuity checks even when wiring is completed. There is no need for unnecessary disconnection and reconnection anymore.

Standard Pin Number Markings

XW4M/XW4N connectors come with clear markings which eliminate the need for additional PCB silkscreen labels or external markings to save board space and preparation time.

Reflow-Compatible Mounting

The connectors support through-hole reflow mounting, which reduces the dependency on manual soldering and aligns well with automated PCB assembly processes. The connectors can be smoothly integrated into existing manufacturing lines without having to add additional special handling steps.

How These Features Translate Into Daily Benefits

Features only matter when they create visible improvements in everyday work. The XW4M/XW4N connectors deliver value across multiple roles on the shop floor and beyond.

Benefits for Assemblers and Technicians

For assembly teams, physical effort and wiring speed are the primary concerns. By eliminating the need for any tightening tools or torque checks, wires can be terminated quickly and consistently. Compared to round or Y-shaped terminals, push-in terminals save up to 60% wiring time by eliminating screwing operation.[1] Being able to mate the connector with one hand with a low-insertion force reduces strain, and can make a meaningful difference for workers during long shifts.

Benefits for Design Engineers

From the perspective of design engineers, XW4M/XW4N supports cleaner layouts and predictable integration. Built-in pin markings make documentation easy and eliminate the need to reserve space on PCBs for labelling.

The availability of multiple pole counts, row configurations, and terminal orientations enhance reusability of the same connector concept for different products.

Benefits for Maintenance Teams

Maintenance teams have to partially disassemble, test and re-assemble the connections under time pressure. Easy insertion, removal and availability of test points means these tasks can be fast and less disruptive. Over a long period, reduced handling steps also reduce wear on both the connector and the cable.

Benefits for Procurement and Operations

Standardizing a connector family simplifies procurement and inventory planning. Fewer part variations result in less overhead during procurement, while improved wire-efficiency reduces the operational costs per unit. Over time, faster assembly and maintenance workflows also support more stable production schedules and reinforce operational efficiency.

A thoughtful connector design can instill productivity across the entire lifecycle of industrial products.

Applications Across Industrial Equipment

As OMRON XW4M/XW4N connectors focus as much on usability as on electrical stability, they naturally fit into a wide range of industrial equipment where wiring density, ease of inspection, and serviceability matter.

In PLC based systems, these connectors simplify I/O wiring and signal distribution. The clear markings and push-in terminations reduce wiring times during initial setup and make modifications easier later when configuration changes or new module additions are required.

For servo drives and robot control systems, multiple signal and power lines are routed into compact enclosures. The availability of different pole counts and right-angled options help manage space constraints in such applications. Single-hand operation is particularly useful when cables need to be supported and access is limited.

The connectors are also well suited for custom automation machines where high-mix production and frequent reconfigurations are a part of normal operation. Reduced wiring efforts and predictable handling help teams adapt quickly without delays.

Across these applications, the XW4M/XW4N series provides a consistent wiring experience.

Practical Design That Strengthens Everyday Productivity

In industrial systems, connectors are often treated as a small detail, but their overall impact on assembly, inspection, and maintenance workflows is anything but small. As the same steps are repeated thousands or millions of times, the design choices that reduce effort and uncertainty have a massive impact on productivity and work quality.

Teams evaluating connectors for their next design can explore more by visiting: OMRON XW4M/XW4N 3.5mm-Pitch Push-In Terminal Block PCB Connectors.

References

[1] OMRON Corporation. User-Friendly XW4M/N Push-in Terminal Block PCB Connectors. Jan 2026. Available from: https://components.omron.com/us-en/sites/components.omron.com.us/files/ds_related_pdf/G150-E1.pdf