Embrioded Electronic Textiles: Solving the textile-to-PCB and ecosystem challenges

Mass manufacturing electronic textiles and in doing so combining textile based wiring and sensors with PCB electronics is no easy task. In this article, you will learn about an innovative approach to enable embriodery of PCBs and conductive wiring/sensors in mass produced e-textiles

Mass manufacturing electronic textiles and in doing so combining textile fibers/garments as well as textile based wiring and sensors with PCB electronics is no easy task. A critical manufacturing challenge here has always been the creation of a reliable high-quality connection between textile wiring/sensors and PCBs/rigid components using a mass manufacturing machine. ZSK has innovated to solve this issue for embroidered electronic textiles. This article originally appeared here.

ZSK will be exhibiting in Berlin at TechBlick's event on RESHAPING ELECTRONICS. Please join us and the entire global community on 17-18 OCT 2023. Lear more here https://www.techblick.com/electronicsreshaped

Solving the textile-to-PCB connection issue

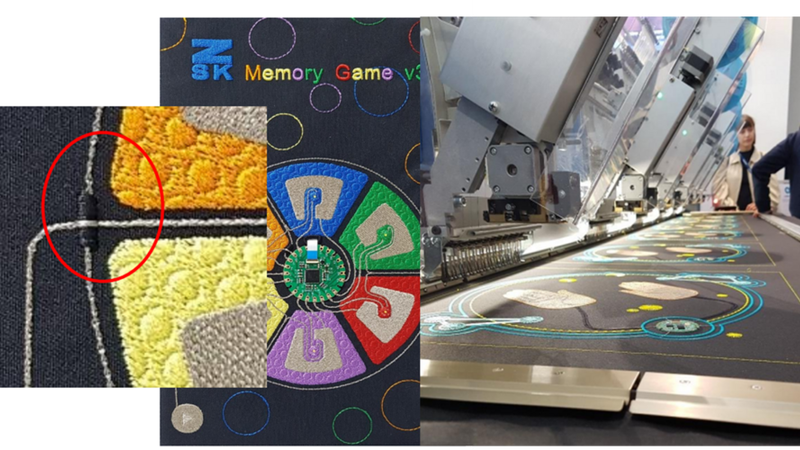

As you can see in slide [1], typically PCBs do not lend themselves well to embroidery of electronics. This is because one often has loose connections, because the high thickness and the sharp edges act as failure points and because the large holes allow movement which loosens the connections. This means that it is not easy to achieve automatic manufacturing with standard PCBs in a reliable way.

This is why - as shown in slide [2] - ZSK developed the ZSK E-Tex-Board, which addresses the above mentioned issues, optimizing the board geometry (hole size, smooth edges, thickness, outer line design, etc) for mass embroidered e-textiles combining textiles wiring/sensors with PCBs.

As shown in slide [3], these special boards are also compatible with automatic placement machines, enabling a fully automatic manufacturing of e-textiles. This is an important step towards the realization of mass embroidered electronic textiles.

These PCBs - together with the ZSK’s F-head for their embroidery machine - enable interesting opportunities. In the F-head, one can embroider the conductive threads with textile/garment to create wiring in the textiles. Using this head, one can also embroider insulating areas as needed, creating cross-overs which vastly improve wiring possibilities in tight spaces.

An example of a full system with embroidered conductive threads [wires] as well as crossovers and a stitched PCBs are shown in slide [3], showing how these innovations bring the entire system together, from conductive yarns to insulating to textile garments to PCBs and electronic components like LEDs etc

Solving the ecosystem issue

ZSK has multiple other embroidery heads for different purposes [K-head for ECG and other sensors based on the moss embroidery and W-head for laying down tubes, fibers etc]. What is however of importance in our view is that they also offer business model innovation

They have correctly realized that the e-textile ecosystem is still immature and full of players each offering only a small part of the full system, which makes it very difficult for a potential end user to develop projects.

To this end, they have launched 3E Smart Solutions - an in-house engineering team - to help companies develop their ideas, prototype them, find manufacturing partners, etc. This fills an important void and we expect will accelerate the development of this industry