Custom Engineered Fans for Reliable Performance in Extreme Environments

Orion Fans developed a custom-engineered fan capable of continuous operation in ozone- and UV-rich environments. The design combines specialized materials, protective coatings, and rigorous validation to ensure long-term reliability and consistent airflow in extreme conditions.

Introduction

Fans are responsible for maintaining the airflow, temperature stability, and system reliability across industrial, commercial, and retail applications. However, when exposed to harsh environmental conditions, fans made with standard materials and coatings degrade fast and fail prematurely. Such demanding applications require fans that are specifically engineered to endure these conditions and perform consistently.

Orion Fans specializes in the design and manufacturing of custom-engineered fan solutions built for harsh and extreme operating conditions. This article explores the technical challenges, engineering approach, and outcomes of designing custom fans for an air purification system that operate continuously in a chamber exposed to extreme ozone and ultraviolet (UV) conditions.

Challenge: When Standards Fail Under Ozone and UV Exposure

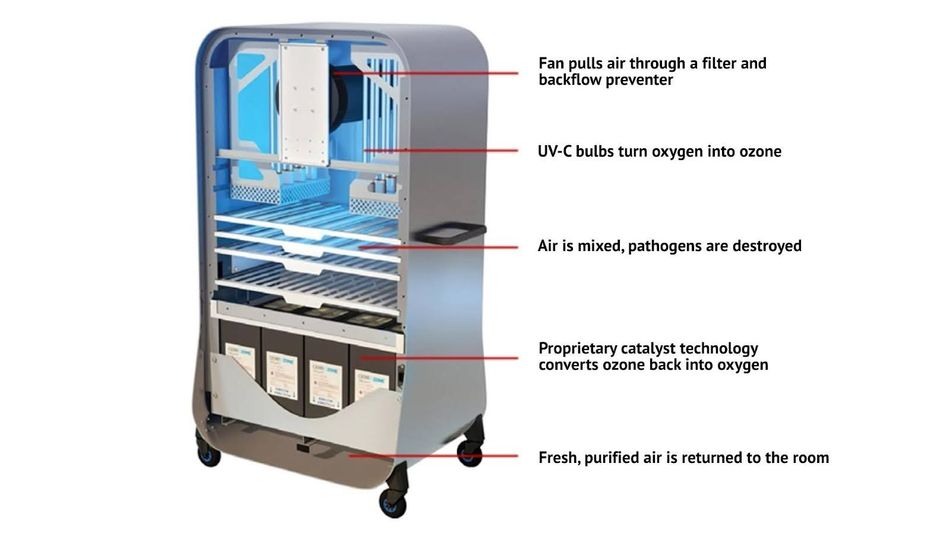

Air purification system fans don’t just move air; they play an active role in the sterilization process. As per the customer’s requirements, the fan was supposed to be positioned in a chamber where ozone and UV were used to neutralize airborne pathogens. The approach was effective for sterilization but proved to be aggressive for the standard fan material used by the customer initially.

The customer tried using standard off-the-shelf fans, but within a matter of just a few weeks, the customer observed clear signs of early fan failure, such as loss of structural integrity and inefficient airflow. The implications went beyond material degradation. The compromised airflow stability reduced the purifier’s ability to effectively sterilize the air, potentially having an impact on user safety.

Commonly used materials in building fan blades, such as Acrylonitrile Butadiene Styrene (ABS), aluminium, and stainless steel, degrade rapidly under continuous ozone and UV exposure. Even materials like Polyamide 66 (PA66), exhibiting excellent strength, rigidity, and chemical resistance, were found to be unfit for this use case. Ozone causes cracking and brittleness in polymers, whereas UV radiation weakens coatings and oxidized metallic surfaces.

The materials suitable for the traditional “harsh environments” failed in this case as they were designed to operate in environments with high amounts of dust, moisture, and chemicals, and not to withstand extreme environments with ozone and UV exposure. Building a fan for this case required a completely different engineering approach.

The challenge was clear: maintain the same form factor, performance, and cost, while achieving the resilience needed for long-term operation in an extreme environment with unusually high oxidative and photochemical stress.

Solution: Engineering a Fan to Withstand Ozone and UV

Overcoming the challenge went beyond replacing materials. It called for a thorough design overhaul and rigorous validation. The Orion engineering team identified the components of the fan that were most vulnerable to ozone and UV degradation and then proceeded to engineer durability into every exposed part of the fan assembly.

Material Innovation and Selection

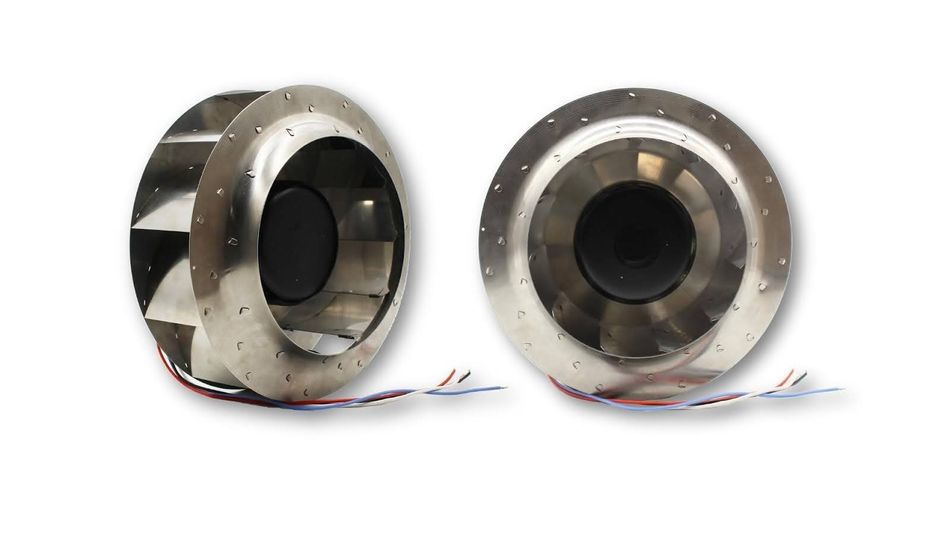

Through accelerated aging tests and material analysis, Orion engineering team selected a combination of 314 Stainless Steel for metal components, Silicone for wire insulation and UV and ozone resistant coatings for the housing. Factors like chemical stability, manufacturability, and costs, were all taken into account while selecting the material for the fans. The team also paid special attention to adhesives and sealants to ensure no outgassing and deterioration under ozone exposure.

Testing and Validation

A small batch of prototype units underwent accelerated life testing inside simulated ozone and UV chambers, replicating thousands of hours of operation. Observations from these tests were shared with the customers to get feedback and guide refinements. The results confirmed that the new material stack successfully managed to maintain mechanical integrity and airflow performance throughout the expected lifespan.

Collaborative Design and Optimization

Enhancing material durability often increases weight, cost, or, in many cases, both. However, with the help of advanced simulation and airflow modelling by Orion, the engineering teams were able to preserve performance efficiency while keeping the impact on the purifier’s overall design and the total cost minimal.

Throughout the development process, Orion’s engineering team worked closely with the customer’s R&D team. This ensured that the trade-offs were carefully managed, and other parameters like airflow curves and mounting geometry were built exactly as per the requirements. The process moved rapidly from concept to production.

Flexible Customization and Deployment

One of the key enablers was Orion’s flexibility throughout the process. The low minimum order quantity (MOQ) requirement allowed the customer to proceed with pilot builds without a large upfront commitment. This flexible, proactive, and collaborative approach resulted in an application-specific fan ready for large-scale production without requiring any redesign of the air purifier from the customer’s end.

“We treated ozone and UV exposure as a design parameter just like dust or moisture,” said Orion’s engineering manager. “That mindset allowed us to find the right materials and validate them quickly.”

Fig. 4: Progression of the air purification system through key development stages

Fig. 4: Progression of the air purification system through key development stages

Results: Proven Reliability, Reduced Waste, and Faster Time-to-Market

The outcome of Orion’s custom engineering process was a fan built specially to perform in a punishing air purification environment.

Technical Outcomes

After a round of rigorous validation, it was confirmed that Orion’s custom engineered fan maintained a life expectancy of 50,000 hours of constant operation under ozone and UV exposure. This is comparable to the life expectancy of standard fans working under normal conditions.

Despite changes in the material and coating, airflow and acoustic performance remained virtually the same. The purifier was able to maintain its sterilization efficiency without requiring any mechanical or software tuning.

In addition to this, the corrosion-resistant material and high-stability polymers, used in the new design, exhibited no measurable degradation after the testing cycles involving fluctuating humidity and temperature. The fan met all the safety standards, ensuring reliable operation at all times.

Business Outcomes

The customer was able to retain the original product concept and design, which helped them avoid additional engineering costs and delays for the market launch. They leveraged Orion’s flexible production and low MOQ facilities to validate their application with a small number of samples before scaling up confidently. The rapid turnaround time of under ten weeks demonstrates the agility of Orion’s custom engineering process while offering the dependability of a global manufacturer.

Sustainability Outcomes

The extended service life of the custom-engineered fan meant fewer replacements over time, leading to lower electronic wastage. The design also prevented unnecessary component scrapping and reduced the environmental footprint associated with redesigning/replacing the failed fans.

Many of the cartons and packaging materials used by Orion are made with over 50% of recycled material, in an attempt to minimize environmental impact.

Conclusion

The project demonstrated how Orion Fans offered reliable performance with custom-engineered fans in extreme environments. Turning challenges into engineering opportunities, the custom solution was able to preserve performance and accelerate time-to-market for the customer.

Manufacturers across industries looking for fans for everyday systems to specialized designs, can get in touch with Orion Fans to get solutions that exactly meet their requirements.