Avestec-SKYRON: The Game-Changing Solution for Container Ship Inspections

Flying robots have emerged as an innovative solution for conducting ship inspections.

Container Ship

Container ships play a vital role in global trade by transporting large quantities of goods and commodities across long distances efficiently and cost-effectively. Time efficiency is critical for container ships because it directly impacts the cost and competitiveness of transporting goods by sea. Along with this, inspection is vital for container ships, as it ensures safety, prevents cargo damage, ensures compliance with environmental regulations, and maintains the ship's value. Inspections help ensure that container ships are operating safely and efficiently, protecting both the crew and the cargo being transported.

Contact-based Ultrasonic Thickness (UT) inspections and visual inspections are fundamental methods used to maintain the safety and reliability of container vessels. These inspections can help identify any issues before they become critical and can ultimately help prevent accidents and other incidents at sea. Regular inspection of cargo ships presents unique challenges due to the massive size of vessels making it difficult to access all compartments, structures, and cargo holds. Conventional methods, such as rope access or scaffolding, can be dangerous and time-consuming. Safety is also a significant concern, as inspectors must be trained to work at height and in confined spaces and must be aware of the potential hazards of working on a large vessel.

Dry docking inspection is a prevalent method for conducting regulated inspections of ship vessels. This method involves taking the container ship out of the water and placing it in a dry dock for an in-depth inspection. Although regulations require dry docking at specific intervals, this process can be costly and time-consuming as the container ship is out of service, resulting in lost value. However, if the inspection does not mandate dry docking, a safer and more time-efficient alternative could significantly reduce costs.

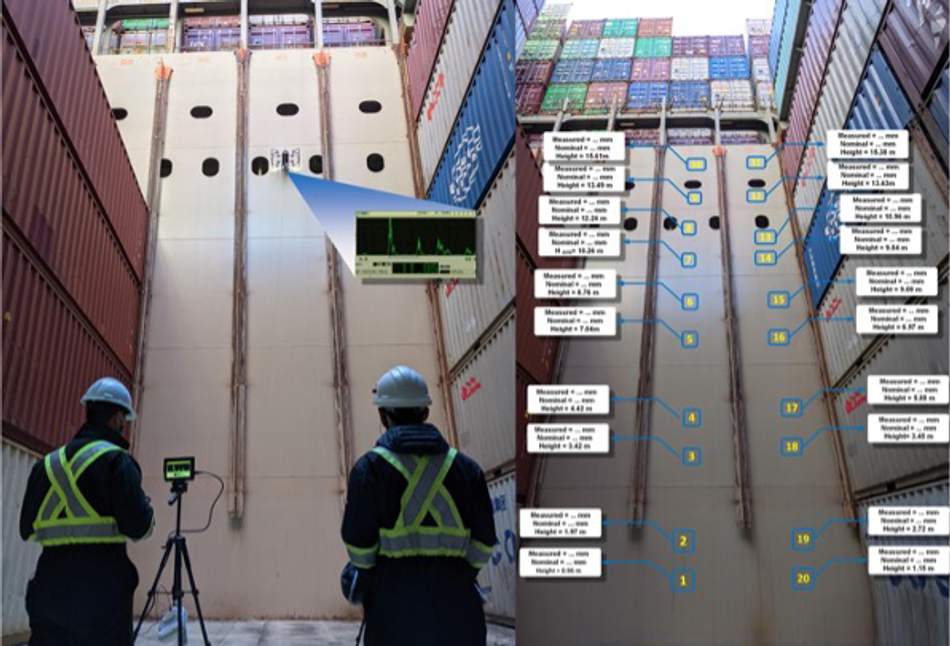

Flying robots have emerged as an innovative solution for conducting ship inspections. Avestec's intelligent flying robot, SKYRON, provides an effective solution to the challenges faced in ship inspections. In a recent inspection, SKYRON conducted UT and visual inspections on a container ship in Vancouver, Canada, on areas such as the aft bulkhead of the cargo hold, cell guides of columns, and waterside hull of the ship. The inspection was carried out while the ship was docking at the port for unloading cargo, making time efficiency critical as the cargo holds are usually refilled with new containers as soon as the unloading is completed. The Avestec crew completed the system setup, safety checks, UT inspection, and close visual inspection in less than an hour.

SKYRON is a highly advanced flying robot that has been designed to carry out different assets' inspections efficiently and accurately. It is equipped with an Olympus 38DL Plus gauge that allows for UT inspections, making it a versatile and multifunctional tool for inspecting ships. In addition to this, the robot is also capable of transforming into a visual inspection flying robot, known as SKYRON VT, which is specifically designed for remote visual inspections and comes equipped with an integrated HD camera that captures high-quality images, a LIDAR range sensor that accurately measures distances, and an advanced lighting system that ensures professional and accurate inspections. These features make the SKYRON VT an ideal tool for conducting detailed and thorough inspections of ships, ensuring that any potential issues are identified and addressed promptly.

The intelligent flying robot measured the thickness of different areas in the cargo ship that may have been corroded or thinned over time. When performing visual inspections, the robot identified any visible defects or damage in the container vessel. Then, the data was captured and analyzed in real-time thanks to Avesoft, a proprietary reporting software that provides an intuitive interface and a dedicated platform for both operators and inspectors, allowing easy access to results by creating automated reports. Overall, the inspection went smoothly, and SKYRON captured 60 UT measurements during 27 minutes of flight time in addition to several high-quality images.

In conclusion, SKYRON is a game-changing innovation in the field of Non-Destructive Testing. With its ability to conduct both ultrasonic thickness and visual inspections using a range of measurement tools, the intelligent flying robot eliminates human risk during inspections, significantly reduces time and costs, and enhances accuracy through data analysis and automation report generation. SKYRON is revolutionizing the way container ships are inspected and maintained, ensuring their safety and reliability.