Alicat Scientific doubles production to support skyrocketing COVID-19 ventilator demand

The fastest flow controller manufacturer in the world doubles production to support skyrocketing COVID-19 ventilator demand for mass flow meters, mass flow controllers, and pressure controllers.

The Business

Alicat Scientific is a pioneer in the manufacturing of mass flow meters, mass flow controllers, and pressure controllers, for gases and liquids. Alicat is part of Halma, a global group of life-saving technology companies.

Task

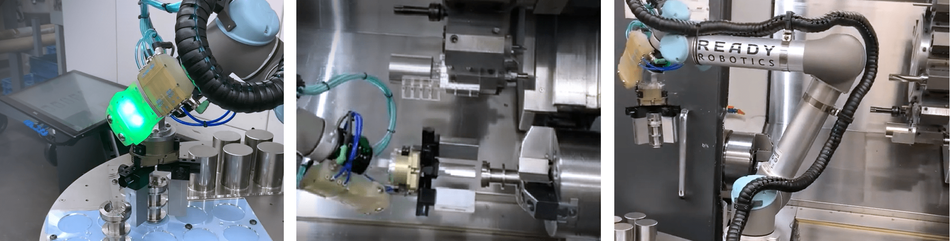

Tending a Takisawa LA 250 YS Lathe

The Challenge

Alicat Scientific sought an automation solution that would allow them to meet their steadily growing demand. Despite increasing their workforce, they’d hit a wall in overall throughput. With cycle times exceeding 45 minutes, machining components on their lathe had become a chokepoint for the rest of their operations. In order to meet demand, they needed to be able to run overnight, when skilled labor is most difficult to come by.

Although they were already looking to automate, COVID-19 related demand increased the urgency at which they needed a solution in production. They couldn’t afford to wait for weeks or months to get a solution designed. And they also couldn’t risk implementing a solution they would be unable to manage in-house and risk downtime. Alicat also needed a solution that could be implemented rapidly by their own people to limit exposure.

From unboxing to training and setup, this was one of the easiest operations I’ve ever experienced in the world of machining. More than that, our machinists actually found it fun!

Greg Camron, Machine Shop ManagerAlicat Scientific

The Solution

After extensive research into the available options, including industrial and collaborative robot manufacturers and custom integrators, Alicat Scientific selected a Forge-powered automation solution from READY. Rapid deployment and ease-of-use were critical decision factors for them. It was also important that their chosen solution was one that they could maintain and troubleshoot themselves - in order to minimize downtime and dependency on third-parties.

The solution consists of a complete hardware package, including robot arm, shipped to Alicat in a crate. What differentiates the READY solution is that everything from the robot arm to the pneumatics is controlled by Forge/OS and programmed with READY’s Task Canvas visual programming application. Alicat got an automation solution they could quickly program and easily maintain with their existing team. Although their machinists hadn't previously programmed an industrial robot, they were able to program their lathe automation task without so much as a training class. In addition, they were able to uncrate and fully deploy their automation task in just three days - with no outside support.

This (automation bundle from READY) solved a critical chokepoint in our ventilator component manufacturing, allowing us to meet COVID-19-related demand that would have been impossible before.

Greg Camron, Machine Shop ManagerAlicat Scientific

The Results

Alicat Scientific received, trained, programmed, deployed, and achieved full ROI in 30 days. Within 8 hours they were comfortable programming automation with Task Canvas. Within three days they had their lathe fully automated. After 10 days they were running lights out. Within 30 days their READY automated solution had already paid for itself.

Automating with READY allowed Alicat to boost output by 74% by adding a “lights out” third shift on weekdays, and another two “lights out” shifts on the weekend. This solution allowed them to achieve constant production on a critical production task. Without automation, machining bobbins for ventilators would have been the bottleneck in their operation, but automating with READY enabled them to expand throughput. Automation enabled them to aggressively scale up production in support of the COVID-19 response.

Highlights

74% boost in output - on a task that would have been a chokepoint

This solution has performed beyond our expectations. From programming it ourselves in three days, to running lights out in 10 days, to paying for itself in the first month - we couldn’t be more pumped. We’re looking for the next task to automate!

Greg Camron, Machine Shop ManagerAlicat Scientific