Agile Industrial Robot Grippers with Topology Optimization & Metal 3D Printing

Preziosa Francesco SRL & Add-it redesigned the grippers of their in-house press brake bending robotic cell for metal 3D printing. The final design was ready for application in just 4 days, increased system reliability, bypassed a supply chain bottleneck, and enabled lights-out manufacturing.

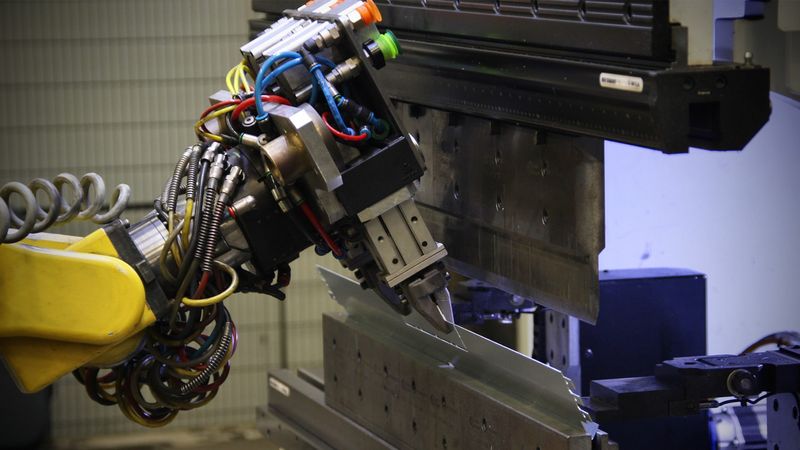

Close-up of the robot with the redesigned gripper in action

This article was first published on

ntopology.comIntroduction

Preziosa Francesco SRL is a manufacturer of sheet metal cabinets based in Bergamo, Italy. They have been leading the Italian market for the past 40 years. Marco Preziosa, the company’s CEO, takes pride in the quality of the products that come out of their factory. He also values his company’s flexibility to customize their standard line to their customers’ specific needs.

The engineers of Preziosa Francesco SRL are always on the lookout for the latest technologies that can improve its processes and workflows and enable them to stay competitive. Today, in the core of their activities lies a robotic cell and an automated press brake bending machine. Yet, this investment worth hundreds of thousand euros is at stake because of a relatively cheap part: the robotic end effector’s gripper.

Robotic grippers are custom components that often need to be changed to meet the requirements of a custom sheet metal job. Preziosa Francesco SRL partnered with Additive Italia (Add-it, for short) to redesign their robot grippers for metal Additive Manufacturing. Add-it is a design consultancy specializing in simulation-driven engineering and generative design.

In this case study, we document how Preziosa Francesco and Add-it used the advanced engineering capabilities of nTopology to create a reusable design workflow for robotic grippers. This way, they improved the system’s performance and bypassed a supply chain challenge.

Practical Robot Gripper Design Challenges

Preziosa Francesco uses a Fanuc M710-iC robotic arm to load metal sheets onto their automatic press brake bending machine, orient and maintain their position during the bending operations, and then store the parts in the appropriate baskets.

The system is equipped with two metal grippers to handle the part during bedding operations. The production team at Preziosa Francesco was facing three main technical challenges related to this simple component. These challenges directly influenced the quality of their products and the productivity of their system:

The standard flat grippers were too slippery. Due to inefficient traction between the sheet metal and the original CNC machined gripper, sheet metal moving during bending, reducing the accuracy of the end product.

The standard grippers were not agile enough. Due to their size, the sides of the gripper were in danger of colliding with the machine at certain bending angles, causing the system to stop.

Manufacturing custom grippers was too slow. Ideally, a different gripper should be used for different sheet thickness and blank size. Outsourcing the job to a CNC machine shop would take at least two weeks, which is unacceptable.

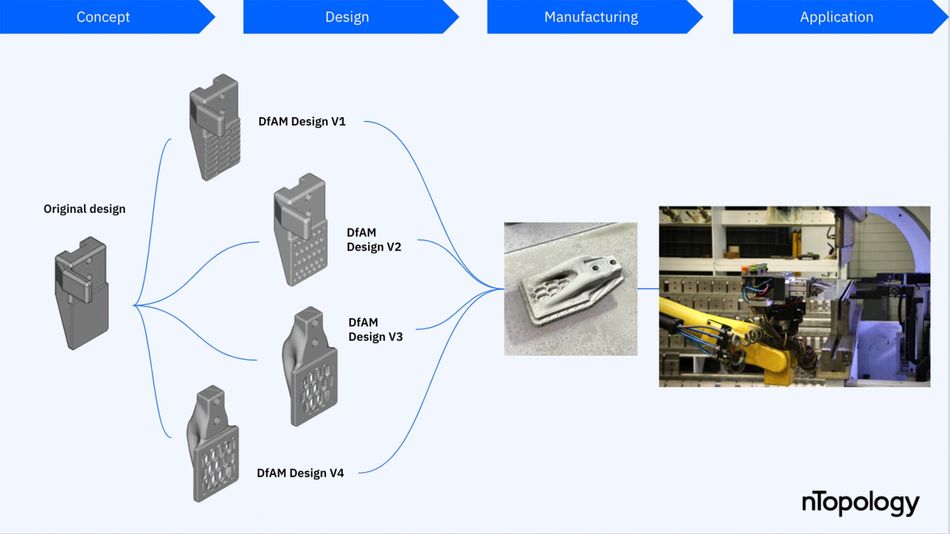

End-to-end Design & Digital Manufacturing Workflow

To overcome these challenges, the engineers of Add-it re-designed the gripper for Additive Manufacturing. They selected metal 3D printing in 17-4 PH stainless steel with Desktop Metal’s Studio System as the manufacturing process due to its ability to quickly produce metal parts in-house.

The team also considered polymer 3D printing as an option but quickly moved away from this solution. For heavy-duty industrial applications, a polymer gripper would wear quickly, loosening the clamping efficiency and reducing the accuracy of the process over time. In this application, repeatability was essential.

A primary goal for this project was to create a process that could be easily replicated. A reusable design process would allow the team to modify the gripper quickly and adjust it to the specific needs of each manufacturing job. This way, the team could create an end-to-end digital manufacturing workflow.

nTopology was a natural choice for the engineering team. “We immediately decided to start this project with nTopology due to the variety of grips that we could make,” mentioned Gianluigi Rossi, the lead design engineer of this project.

Increasing Grip Force using Lattice Structures

Friction is often not enough to ensure a good grip, especially when precise positioning under high loading conditions is required. A common way to increase grip — and hence the reliability of the bending process — is to add a traction pattern to the robot gripper. The grooves of a traction pattern cause the softer material to deform (in this case, the aluminum sheet), mechanically interlocking the parts together and increasing grip.

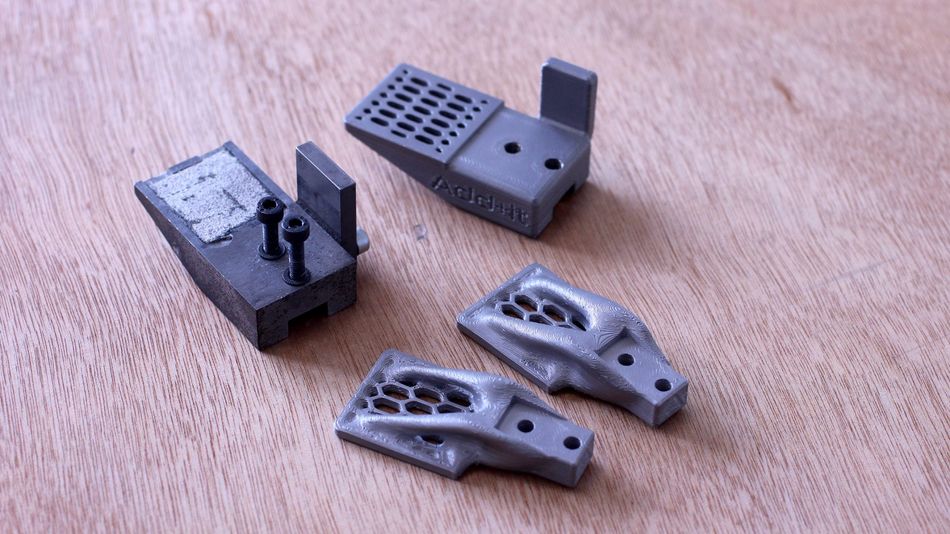

The engineers of Add-it experimented with two initial design variations. First, they consolidated the assembly of the gripper and the stop reference into a single component. Then, they applied two different patterns to the gripper: grooves created using a surface lattice and honeycomb-like perforation pattern. The goal of this conservative DfAM redesign was to test the accuracy of the metal 3D printing process.

They found through testing that the honeycomb-like perforation pattern provided better traction and was easier to manufacture using metal 3D printing. This design was used as a basis for the later iterations.

What stood out to the team during this project was the speed of iterations. They moved from concept to application in less than 4 days. This rapid momentum was enabled to a large extent by the design capabilities of nTopology.

“Shifting from classic CAD software to nTopology is a radical leap. I interfaced with another way of working and thinking. This software can open new paths, such as reusing the same workflow for other geometries and sharing it with colleagues. This is a unique time-saving in the working environment. In one afternoon, we managed to make the component we needed. In a few minutes, we could change the type of grip and produce a part that was ready to manufacture.”

Gianluigi Rossi, Design Engineer, Add-it

Topology Optimization to Design More Agile Robots

The closer the gripper can reach the press brake, the safer and more repeatable the process can get. However, even small variations in sheet thickness can cause the gripper to collide with the machine tool at certain angles, resulting in stops. Replacing the standard gripper with a more slender design expands the robot’s safe zone and increases its agility.

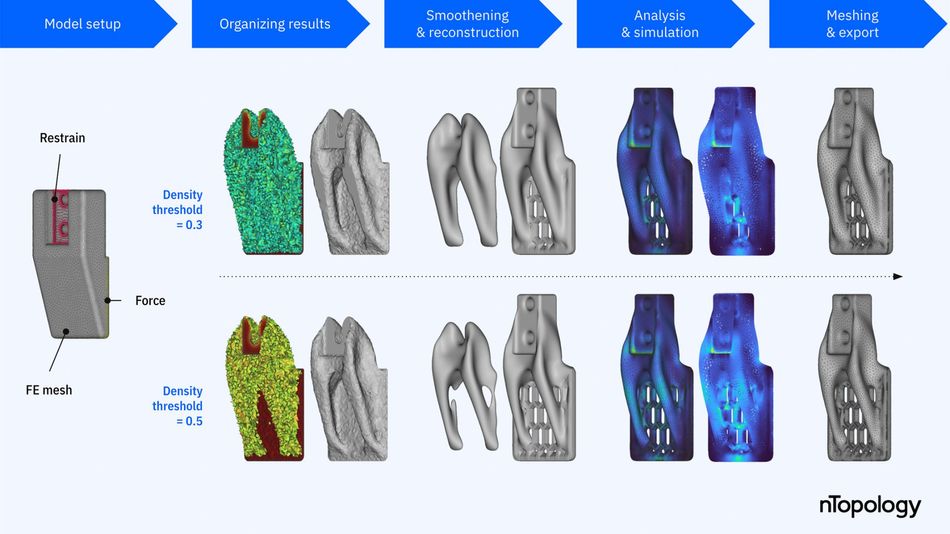

This was the objective of the second design iteration. The engineers of Add-it used nTopology’s built-in topology optimization capabilities to generate a gripper with optimized geometry. The primary goal was not to reduce the part’s weight but to create a design with similar performance — stiffness, grip force, weight — but a smaller footprint.

The topology optimized gripper enabled the system to perform more delicate robotic operations and handle smaller metal sheets. “We estimated the space that we needed to save in the volume of the clamps. It was a matter of a few millimeters. Still, it was a few millimeters that counted in this application,” Rossi notes.

The team designed and 3D printed two variations of the topology optimized gripper using two different levels for the density threshold. Using nTopology, Rossi automatically reconstructed and smoothened the topology optimization results, bypassing a time-consuming manual step that is common in other software. Since the team didn’t have to recreate the part geometry manually, multiple variations could be generated with only a few clicks.

In fact, when Add-it first started using nTopology, they used to import results of third part topology optimization tools in nTopology — like Altair Optistruct® — just to take advantage of the software’s automated reconstruction capabilities. Now, the Add-it team is using nTopology for all their topology optimization needs due to its streamlined workflows and greater level control.

Ensuring Process Reliability with Reusable Design Processes

Every unforeseen change in the design has an impact on the quality of the end product. In the case of the gripper, even a few millimeters can make your process reliable or unreliable. The more flexible you are at adapting your tools to an ever-changing environment, the better the chances to succeed as a business.

For Preziosa Francesco, the redesigned gripper greatly improved process reliability. By eliminating stops, it unlocked lights-out manufacturing and the full utilization of their robotic manufacturing system.

Additionally, the ability to produce the parts they needed in-house in a few days enables Preziosa Francesco to adapt their system on short notice. They can also revisit their processes when necessary. The reusable design workflows created in nTopology were the missing link for taking full advantage of its Desktop Metal Studio System’s manufacturing capabilities.

“If you don’t have a very repeatable process, you are forced to run production only during the day. It is very economically difficult to have these machines operate during day-shift only. Theoretically, you can have a very clever production system. But if it doesn’t work as intended because of a cheap part, an investment worth hundreds of thousands is at stake. nTopology allowed us to use robotic manufacturing our Desktop Metal Studio System to its full potential.”

Marco Preziosa, CEO, Preziosa Francesco SRL

The Next Steps

With the new grippers proving their value in action, Preziosca Francesco SLR and Add-it are now looking to replicate this process of other applications. For example, they are designing clamp replacements and spare parts for the company’s punching machine.

As for improvements on the existing workflow, the engineers of Add-it are now investigating how to create a new topology optimized version of the gripper that is twice as long while remaining durable and reliable. This way, they would generate a customizable clamping tool that is even more maneuverable and flexible.

This article was first published on the nTopology blog.