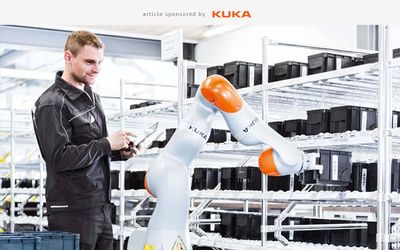

KUKA LBR iiwa

A lightweight robot for delicate assembly work, safety fences make way for Human Robot Colaboration

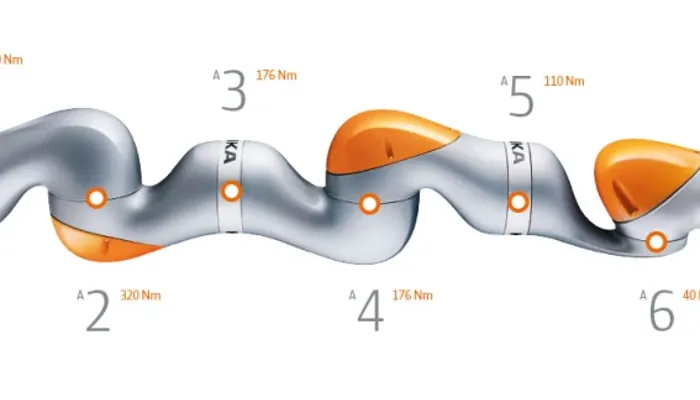

Technical Specifications

| Payload | |

| - LBR iiwa 7 R800 | 7 |

| - LBR iiwa 7 R800 CR | 7 |

| - LBR iiwa 14 R820 | 14 |

| Maximum reach | 800 |

| - LBR iiwa 7 R800 | 800 |

| - LBR iiwa 7 R800 CR | 820 |

| - LBR iiwa 14 R820 | |

| Mounting positions | |

| - LBR iiwa 7 R800 | |

| - LBR iiwa 7 R800 CR | |

| - LBR iiwa 14 R820 | |

| Protection class |

Overview

Quick reactions

Thanks to its joint torque sensors, the LBR iiwa can detect contact immediately and reduces its level of force and speed instantly. Its position and compliance control enables it to handle delicate components without creating crushing and shearing hazards.

Able to learn

The user can choose from three operating modes and program the LBR iiwa via simulation: indicate the desired position and it will remember the coordinates of the path point. Stop for breaks and control it with simple touch commands.

Sensitive

The LBR iiwa with its high-performance servo control is able to detect contours quickly under force control. It establishes the correct installation position and mounts components quickly and with the utmost precision with an axis-specific torque accuracy of ±2% of the maximum torque. The LBR iiwa can also find small, delicate components in next to no time without your assistance.

Independent

The LBR iiwa's controller, KUKA Sunrise Cabinet, simplifies the quick start-up of even complex applications. It gives the operator a third hand and has the LBR iiwa take care of unergonomic, monotonous tasks reliably and independently.

Media flange options

The energy supply system for the external components is hidden in the kinematic structure of the LBR iiwa. Pneumatic and electrical energy supply systems are available. All media flanges have a hole pattern conforming to DIN ISO 9409-1-50-7-M6.

References

Contains elaborate description of the robotic arm, images, and video's. Also describes the multiple applications.

Elaborate brochure describing the technology, technicalities, and specifications.

Recommended Specs

Continue Reading

Could this be the time we say goodbye to robotic awkwardness and hello to seamless motion? This article highlights the groundbreaking concept of whole-body control, a coordinated robotic motion technique that resembles natural movement. Imagine a robot smoothly navigating its environment, performing tasks with grace and precision. This innovative approach allows for improved efficiency and greater versatility in real-world settings.