Sidekick: A Low-Cost Open-Source 3D-printed liquid dispensing robot

A low-cost open-source 3D-printed desktop robot for microplates liquid dispensing.

Technical Specifications

| Minimum Area | 275 mm x 215 mm x 161 mm |

| Reachable area | 131 mm x 176.5 mm |

| Microcontroller | Raspberry Pi Pico |

| Power: 5 V USB | |

| 3D printed parts | Material: PETG or PLA |

| Armature | 2 DOF parallel manipulator with a four bar linkage system |

| four 3D-printed arms; connected at each joint by 10 mm ball bearings | |

| Microplate | single 96-well SBS microplate |

| Motor | 2 NEMA 17 pancake stepper motors |

| 12 V at 1A per phase | |

| Holding torque: 11 N/cm | |

| Motor Driver | TMC 2209 |

| Pump System | positive displacement pumps (Lee Company) |

| 12-volt square wave | |

| 10 uL variants (LPMA1250110L) | |

| Pump controller | ULN2803A Darlington Array |

Overview

This tech spec was submitted by Keesey Rodolfo as part of the University Technology Exposure Program.

Problem / Solution

Automation alone improves productivity, more so when combined with artificial intelligence. Research on this collaboration has marked up in material science and chemistry. But as studies grow more complex, demand for better experiment tools arises. One instrumental device in chemical experiments is liquid handlers, which come with quite a price reaching up to tens of thousands of dollars. And while open source hardware tries to reduce this gap, it is hard to outsource the materials needed. Likewise, there are concerns about construction and maintenance costs as it takes long hours to build one. This issue increases the actual system cost while reducing the opportunity for device adoption.

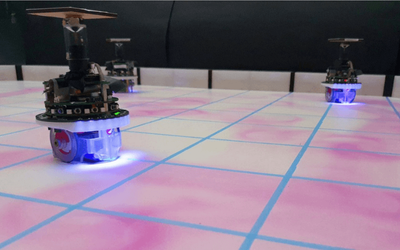

Integrating an easy access laboratory automation in liquid handling, developers initiate the forming of a desktop liquid dispenser called the Sidekick. This armature-based system features a 3D-printed chassis in hopes of reducing mechanical complexity and dispenses 10 uL liquid increments using four solenoid-driven pumps. At only $710, Sidekick narrows the cost issue while being easy to build and maintain, open-sourced, and matching compatibility standards with Society for Biomolecular Sciences (SBS) microplates.

Design

Armature-based system

In Sidekick, the cartesian movement system is replaced with an armature-based system to simplify the overall assembly of the device. The 3D printing of the chassis also eliminates the sourcing of materials while reducing its cost by using Polyethylene terephthalate (PETG) or Polylactic acid(PLA). The user can also customize the device depending on the functionality requirements.

The transition to an armature-based design lowers the number of parts but increases the capacity of printable components. The four-bar-linked parallel manipulator, inspired by drawing robots, simplifies the mechanical complexity to optimize build time, machine size, and cost. This parallel configuration allows the mourning of the driving motors to the base of the linkage system—resulting in weight and footprint reduction of the device. There are only 19 parts needed to assemble the machine within four hours at only $152. Along with the armature working area, Sidekick measures 275 mm long, 215 mm wide, and 161 mm high. The device can work in space-limited areas with high position accuracy given its home system and stepper motors.

Pumps

The four various pumps dispense four different liquids at 10uL increments. These micropumps are advantageous as there is no need for calibration, thus reducing both initial and maintenance costs. In case of damage, replacement is easy since they are modular. If the flow rate needs adjustment, adding other open sources to the device is possible. However, Sidekick cannot perform liquid aspiration that could have allowed serial dilution.

Commercial pumps from the Lee Company show the best performance while being nonchemical reactive. A 12-volt square wave energizes the device to trigger the dispensing increment upon being energized and unenergized. These polyether ether ketone (PEEK) and fluoroelastomer (FKM) pumps are calibration-free, thus providing reliable performance while being user-friendly. A downside of these pumps is their lack of aspiration capability, as they can only draw liquid from a fixed reservoir.

Tubings

The 1/3200 ID PTFE tubing carves the path from the source reservoir toward the target area. This narrow tubing decreases dripping as it has a reduced cross-section. It is also flexible and can reduce resistance within the armature during the bending of the tube upon liquid travel.

Motors

Using NEMA 17 stepper motors, precision at a small footprint is within reach. The motor is set to a 0.9° step-angle, setting the baseline angular resolution requirement of Sidekick. This micro stepping likewise allows larger angular resolution, where a 1.8-degree stepper can be used to further reduce cost. The test results show a 1mm precision in centering the end effector given the 0.9-degree step at ⅛ micro-stepping. The low armature resistance in the motor also eliminates loss in closed loop controls and the likelihood of the device skipping steps.

For motor control, TMC 2209 proves to be the best candidate when it comes to thermal, accuracy, and noise. These drivers offer high stepping capabilities at almost zero noise. Joined with two limit switches that mark the motor armature’s default position, the module drives precision and accurate motion. Given future considerations of removing the need for such limit switches, the drivers installed with stall protection allow feedback checking, which can increase reliability.

Software

Raspberry Pi Pico controls Sidekick under the MicroPython program. Calculations performed on the Pico mirror the armature angular position. The program also incorporates text commands via a serial port that can control the device using any programming language. With such features, the user can command simple instructions, like identifying the pump to use, the volume of dispersion, and location targeting, and infuse G-code common subsets.

The Raspberry Pi Pico-controlled Sidekick runs on a 5V USB bus, whereas the stepper motors run on a 12V, 5A supply. The unused pins of the Pico serve as routes for additional hardware depending on the user's needs. All of the components are PCB mounted-designed in Fritzing.

References

A research paper describing the challenge, design, and outcome of the research.