Fetch Mobile Manipulator

The Fetch Mobile Manipulator provides a fully integrated standard platform for mobile manipulation research. Fetch uses a relatively large and capable mobile manipulator (Fetch) to pick items off of warehouse shelves. The back-drivable 7 DOF arm is capable of lifting 6 kilograms, this is a large enough payload to handle the vast majority (90-95 percent) of all items in a typical warehouse.

Technical Specifications

| Weight | 113.3 |

| Height | 1,096 |

| 1,491 | |

| Base footprint | |

| Max speed | |

| Degrees of freedom | |

| 7-DOF arm | |

| Payload | 6 |

| Arm length to gripper mount | 940.5 |

| Max end effector speed | 1.0 |

| Sensors | |

| 2D laser | 25 |

| 220 | |

| 3D RGB-D | |

| IMU (2) | 6 |

| Gripper | |

| Max grasp force | 245 |

| Max gripper opening | 100 |

| Computer | |

| Processor | |

| RAM | |

| Hard drive | 120 |

| Wireless | |

| Speaker | |

| Installed software | |

| Installed applications |

Overview

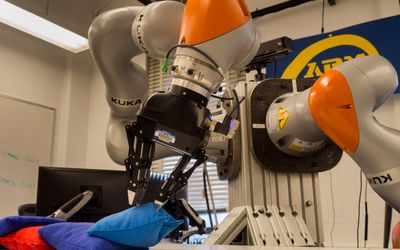

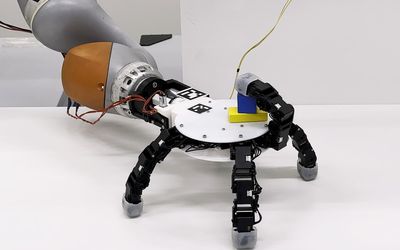

The robot consists of a differential drive mobile base, an arm, a pan and tilt head, a torso lift actuator, and a stan-dalone mobile robot platform. The mobile base includesa SICK laser scanner with a 220 degree field of view and 25 meter range. It's base also includes a base-mounted 3D camera. Fetch includes a head-mounted Primesense Carmine 1.09 depth camera. The gripper is a modularity point, allows custom grippers to be swapped in, but supplied with a default parallel-jaw gripper capable of grasping a wide range of objects. Intel-based computersprovide processing power for navigation, manipulation and perception activities.

The back-drivable 7 DOF arm is capable of lifting 6 kilograms, this is a large enough payload to handle the vast majority (90-95 percent) of all items in a typical warehouse.

The robot is suitable for normal human work environments. Fetch is primarily developed for shelf picking, but the robot is also designed to work well in homes and labs. The arm is designed specifically to be able to reach items on the ground, enabling recovery if an item is dropped during manipulation.

The mobile base is driven by two brushless hub motors in a differential drive configuration. Each hub motor is held in a drop suspension configuration, allowing the robot to keep traction when crossing obstacles, without allowing the robot to sway side-to-side when manipulating on flat ground. Four casters provide stability duringmovement.

Each of the Fetch arm joints are built from a harmonic drive coupled to a brushless frameless motor, mounted inside a custom cast aluminum housing. Each joint has two 14-bit absolute magnetic encoders, one coupled to the joint output shaft, and one coupled to the motor backshaft.

The robot has sufficient battery power to work an 8-hour day. This requirement affects both the battery selection as well as other power-related trade-offs such as the choice of the computer processor and communication buses.

References

Elaborate overview of Fetch's specifications, it's degrees of freedom, and it's measurements.

Introduces the technology, related design, and goes into the Fetch robot design. Describes it's applications, and testing.