Wire mesh for efficient handling of hydrogen

The role of renewable energy and hydrogen as an alternative energy source is of interest to many modern industries. Hydrogen is cleaner, more efficient and more sustainable than fossil fuels and has the potential to replace them.

The role of renewable energy and hydrogen as an alternative energy source is of interest to many modern industries. Hydrogen is cleaner, more efficient and more sustainable than fossil fuels and has the potential to replace them. A significant contribution to the fight against climate change is therefore within reach. However, there are technical challenges to overcome in the production, transport and storage of the medium.

The quest for sustainability is leading companies such as Haver & Boecker to focus their strategies on renewable energy and green hydrogen. Although abundant, hydrogen is bound in nature and requires efficient processes to release it. This is where research comes in to develop and optimise such processes.

Technological leader in hydrogen technology

Haver & Boecker is actively involved in the development of solutions for hydrogen technology. A key element is wire mesh, which plays a crucial role in both the production and application of hydrogen. The company is continuously working to meet the challenges of handling the medium.

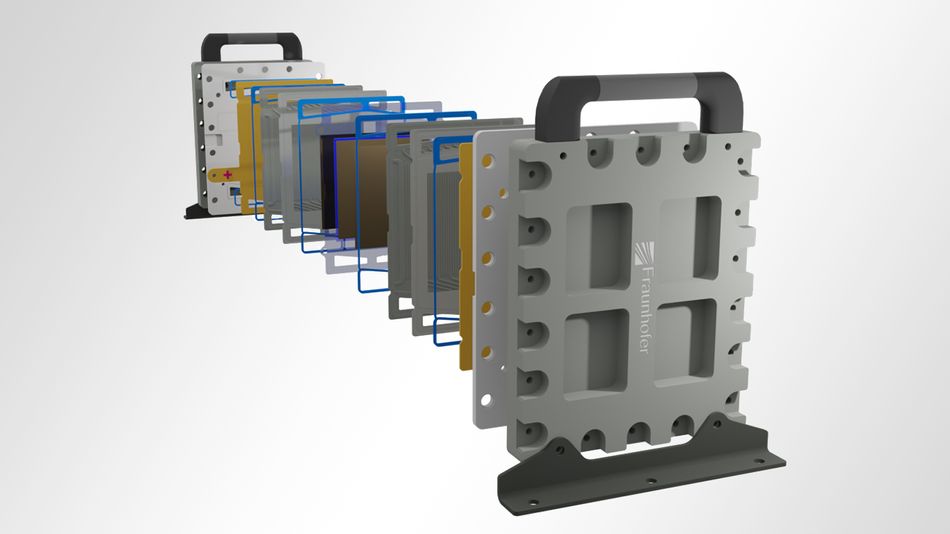

Example of PEM fuel cells

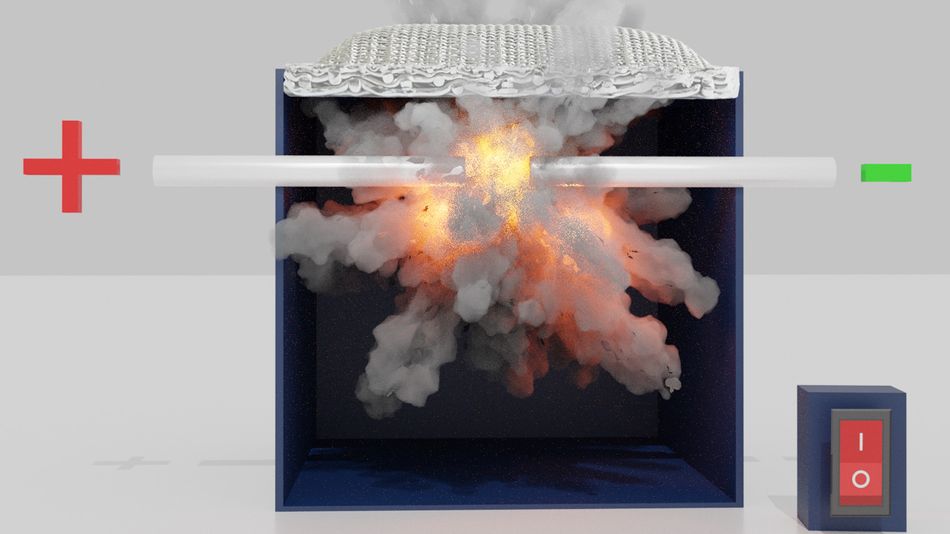

High-purity hydrogen is critical because impurities such as carbon monoxide, sulphur compounds or ammonia can damage the platinum catalysts and reduce their efficiency. Even small amounts of impurities can cause chemical reactions that attack the fuel cell membrane, resulting in reduced performance or complete system failure. Filtering the hydrogen to a high level of purity is therefore essential to ensure durability, reliability and maximum performance.

Haver & Boecker woven wire cloth removes contaminants by filtering out not only chemical particles but also micro-organisms. This ensures a high level of hydrogen purity, which is essential for optimum performance and longevity of PEM fuel cell systems.

Other applications

Wire mesh already plays a vital role in the manufacturing process. It is used in various electrolysis processes such as alkaline, PEM and high-temperature electrolysis. As a component of anodes and cathodes, it makes a significant contribution to efficient and rapid hydrogen production. The following key factors should be highlighted:

- The wire mesh provides a larger surface area for electrochemical reactions. This is particularly important in water electrolysis where hydrogen is produced at the cathode. A larger active surface area results in more efficient and faster hydrogen production.

- The electrical conductivity in the electrodes is improved. This is essential to reduce the resistance in the electrolysis system, which increases the efficiency of hydrogen production.

- The reactants (such as water) are evenly distributed over the electrode. This ensures more efficient use of the electrolyte and prevents local hotspots that could reduce performance.

- The wire mesh provides structural support and durability for the electrodes, which is particularly important to ensure the long-term stability and reliability of the electrolysis system.

The mesh is particularly resistant to the chemical and physical properties of hydrogen, such as its considerable reactivity and the high pressures encountered during transport.

Another advantage is its customisability: the product can be manufactured individually according to specific requirements and specifications, providing a tailor-made solution for different applications. This flexibility makes it possible to configure wire mesh for a wide range of applications, whether for filtration, separation or reinforcement, to meet specific handling and transport requirements.

A look at the future

Haver & Boecker is constantly working to improve the efficiency and safety of hydrogen handling and to further optimise its proven technology. This includes the development of heavy-duty wire meshes for various applications, from electromobility to the chemical industry. Through continuous innovation and collaboration with other companies and institutes, the company is making a significant contribution to the energy transition.