VOC Sensors: A Comprehensive Guide to Their Applications and Maintenance

Volatile Organic Compounds (VOC) sensors are key in detecting potentially dangerous air quality.

Introduction

Volatile Organic Compounds (VOCs) are ubiquitous in our environment, emanating from a variety of sources such as paints, cleaning supplies, and even certain types of food. The detection and monitoring of these compounds are crucial due to their potential health and environmental impacts. VOC sensors play a pivotal role in this process, providing vital data that can be used to control and reduce exposure to these compounds. These sensors find applications in a wide range of industries, from indoor air quality monitoring in buildings to emission control in industrial processes. Understanding the technology behind VOC sensors, their operation, and their applications can help us appreciate their importance in maintaining a safe and healthy environment.

What are VOCs?

Volatile Organic Compounds, commonly referred to as VOCs, are a group of carbon-based chemicals that have high vapor pressure at room temperature due to their low boiling point. This characteristic makes them volatile, meaning they can easily evaporate or sublimate from their solid or liquid state into the air. VOCs are produced by a wide array of products numbering in the thousands.

Common sources of VOCs include paints, varnishes, wax, and many cleaning, disinfecting, cosmetic, degreasing, and hobby products. In addition, VOCs are released from burning fuel such as gasoline, wood, coal, or natural gas. They are also emitted from certain types of food and beverages.

The health effects of VOCs can vary greatly, from those that are harmless to those that are toxic. Some VOCs, like benzene and formaldehyde, are known human carcinogens, while others can cause eye, nose, and throat irritation, shortness of breath, headaches, fatigue, nausea, dizziness, and skin problems. Prolonged exposure to certain VOCs can lead to liver, kidney, or central nervous system damage, and some can cause cancer.

From an environmental perspective, VOCs contribute to the formation of ground-level ozone, or smog, which can have detrimental effects on the environment and human health. They can also contribute to indoor air pollution, which the Environmental Protection Agency (EPA) lists as one of the top five environmental risks to public health.

Monitoring and controlling VOC levels is therefore of paramount importance. This is where VOC sensors come into play. These devices can detect and measure the concentration of VOCs in the environment, providing crucial data that can be used to control and reduce exposure to these potentially harmful compounds.

VOC Sensor Technologies

VOC sensors are designed to detect and measure the concentration of volatile organic compounds in the environment. There are several technologies used in the design of these sensors, each with its unique working principle, advantages, and disadvantages.

Metal Oxide Semiconductor (MOS) Sensors

Metal Oxide Semiconductor (MOS) sensors are a common type of VOC sensor. They operate based on the principle of change in resistance of a metal oxide layer when exposed to VOCs. The sensor consists of a heating element and a metal oxide layer. When the heating element raises the temperature of the metal oxide layer, it becomes sensitive to gases in the environment.

When VOCs come into contact with the heated metal oxide layer, they react with the surface, causing a change in the electrical resistance of the layer. This change in resistance is proportional to the concentration of VOCs and can be measured to determine the VOC level.

MOS sensors are widely used due to their low cost and ability to detect a wide range of VOCs. However, they have some limitations. For instance, they are sensitive to changes in humidity and temperature, which can affect their accuracy. They also have a relatively short lifespan compared to other sensor technologies, typically around 2 years.

MOS sensors are commonly used in applications such as indoor air quality monitoring and industrial leak detection. For example, they can be used in office buildings to monitor the levels of VOCs emitted from office equipment, cleaning products, and building materials. In industrial settings, they can be used to detect leaks of VOCs from storage tanks and pipelines.

Photoionization Detectors (PIDs)

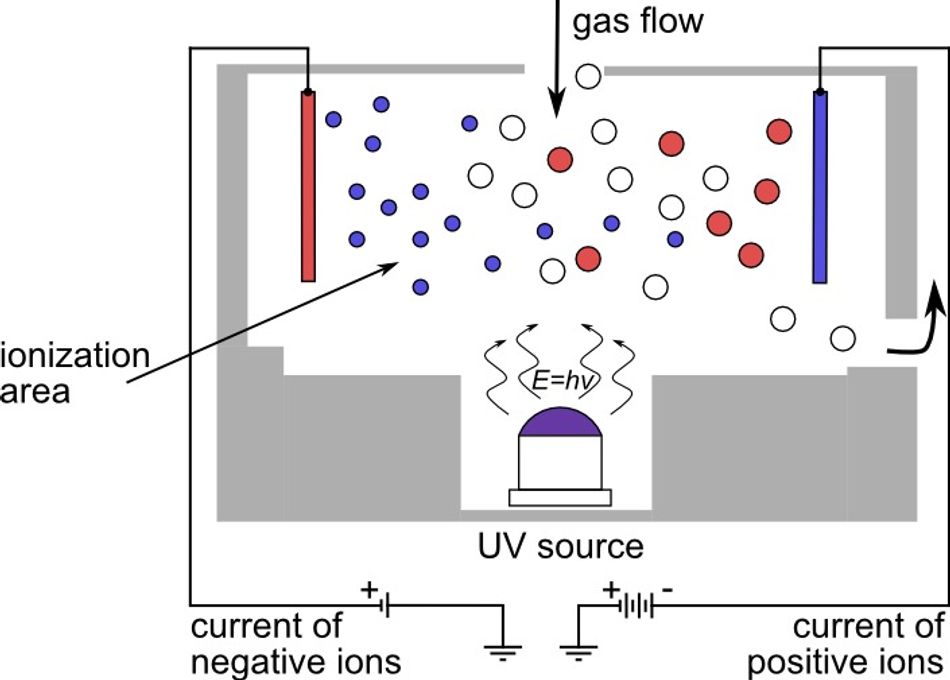

Photoionization Detectors (PIDs) are another type of VOC sensor that operates on a different principle than MOS sensors. PIDs use ultraviolet (UV) light to ionize the VOCs. The ionization process involves the absorption of UV light by the VOC molecules, which results in the ejection of an electron and the formation of a positively charged ion. The concentration of VOCs is then determined by measuring the current produced by the movement of these ions.

PIDs are particularly effective at detecting low concentrations of VOCs, with some models capable of detecting levels as low as parts per billion (ppb). They are also known for their fast response times, often in the range of seconds, making them suitable for applications where rapid detection of VOCs is critical.

However, PIDs also have their limitations. They are not effective at detecting compounds with an ionization energy higher than the UV lamp's energy. This means that some VOCs may not be detected by a PID. Additionally, PIDs can be more expensive than other types of VOC sensors, and they require regular maintenance to replace the UV lamp and clean the ionization chamber.

Despite these limitations, PIDs are widely used in a variety of applications. They are commonly found in industrial hygiene and safety applications, where they are used to detect VOC leaks and ensure worker safety. They are also used in environmental monitoring to detect VOC emissions and contribute to pollution control efforts. For example, PIDs can be used to monitor the air quality in urban areas, detecting VOCs emitted from vehicle exhaust and industrial processes.

Infrared (IR) Sensors

Infrared (IR) sensors represent another technology used in the detection of VOCs. These sensors operate based on the principle of infrared absorption spectroscopy. In this process, VOC molecules absorb infrared light at specific wavelengths, causing them to vibrate. By measuring the amount of light absorbed, the sensor can determine the concentration of VOCs.

One of the key advantages of IR sensors is their high selectivity. Because each VOC absorbs infrared light at a unique set of wavelengths, IR sensors can be used to detect specific VOCs with high accuracy. This makes them particularly useful in applications where it's important to distinguish between different types of VOCs.

IR sensors also offer long-term stability and do not suffer from sensor drift, a common issue with some other types of VOC sensors. This means they can provide reliable measurements over extended periods of time. However, they are not as sensitive to low concentrations of VOCs as PIDs, and they can be more expensive.

In terms of applications, IR sensors are often used in industrial settings where specific VOCs need to be monitored. For instance, they can be used in the petrochemical industry to detect leaks of specific hydrocarbons. They are also used in environmental monitoring, where they can help track the emission of specific VOCs from industrial processes.

Factors Affecting VOC Sensor Performance

The performance of VOC sensors can be influenced by a variety of factors. Understanding these factors is crucial for the accurate interpretation of sensor data and for the design of more effective and reliable sensors.

Temperature and Humidity

Temperature and humidity are two environmental factors that can significantly impact the performance of VOC sensors.

In the case of temperature, it can affect the sensor's sensitivity and response time. For instance, in MOS sensors, the temperature influences the rate of reaction between the VOCs and the metal oxide layer. A higher temperature can increase the reaction rate, leading to a faster response time. However, it can also increase the sensor's sensitivity to other gases, potentially leading to false readings.

Humidity, on the other hand, can affect the sensor's ability to detect VOCs. High humidity can cause condensation on the sensor surface, which can interfere with the interaction between the VOCs and the sensor material. This can result in lower sensitivity and slower response times.

To compensate for these effects, some VOC sensors incorporate temperature and humidity compensation mechanisms. For example, they may include additional sensors to measure the ambient temperature and humidity, and use this data to adjust the VOC readings. This can help to improve the accuracy of the sensor in different environmental conditions.

Despite these challenges, temperature and humidity effects are an active area of research in VOC sensor design, with ongoing efforts to develop sensors that are less sensitive to these environmental factors.

Cross-Sensitivity

Cross-sensitivity refers to a sensor's response to gases other than the target VOC. This is a common challenge in VOC sensor design, as many sensors respond to a wide range of gases, not just the target VOCs.

For instance, MOS sensors, while being able to detect a wide range of VOCs, are also sensitive to other gases such as carbon monoxide and hydrogen. This means that the presence of these gases can cause the sensor to give a higher reading than the actual VOC concentration. This can lead to false alarms or inaccurate measurements of VOC levels.

Similarly, PIDs, despite their high sensitivity to low concentrations of VOCs, can also respond to other gases. For instance, they can be sensitive to moisture and other non-VOC gases that can ionize under UV light. This can lead to overestimation of VOC levels in humid conditions or in the presence of other ionizable gases.

Cross-sensitivity is a significant challenge in VOC sensor design and can affect the accuracy and reliability of the sensor. To address this issue, sensor manufacturers often provide correction factors for common interfering gases. These factors can be used to adjust the sensor readings and improve the accuracy of the VOC measurements.

In addition, research is ongoing to develop more selective VOC sensors. For example, researchers are exploring the use of new sensor materials and designs that can selectively respond to specific VOCs, thereby reducing cross-sensitivity. Despite these challenges, the development of more selective and accurate VOC sensors remains a key goal in the field of gas sensing technology.

Sensor Drift

Sensor drift is a phenomenon that affects the performance of VOC sensors over time. It refers to the gradual change in the sensor's output signal, even when the concentration of the target VOC remains constant. This can lead to inaccurate measurements and reduced reliability of the sensor.

There are several factors that can contribute to sensor drift. One common cause is the degradation of the sensor material due to prolonged exposure to VOCs, humidity, or other environmental factors. For example, in MOS sensors, the metal oxide layer can undergo changes in its chemical composition or structure over time, which can affect its sensitivity to VOCs. Similarly, in PIDs, the UV lamp can degrade over time, leading to a decrease in the ionization efficiency and a corresponding decrease in the sensor's sensitivity.

Another factor that can contribute to sensor drift is the accumulation of contaminants on the sensor surface. This can occur when dust, dirt, or other particles adhere to the sensor, interfering with the interaction between the VOCs and the sensor material. This can result in a gradual decrease in the sensor's sensitivity and response time.

To mitigate sensor drift, regular maintenance and calibration of VOC sensors are essential. Maintenance practices may include cleaning the sensor surface, replacing the UV lamp in PIDs, or replacing the metal oxide layer in MOS sensors. Calibration involves exposing the sensor to a known concentration of the target VOC and adjusting the sensor's output signal to match the known concentration. This process helps to ensure that the sensor remains accurate and reliable over time.

In addition to these maintenance and calibration practices, ongoing research is focused on developing new sensor materials and designs that are more resistant to drift. This includes the exploration of novel materials with improved stability and the development of sensor designs that minimize the impact of environmental factors on sensor performance.

VOC Sensor Calibration and Maintenance

The calibration and maintenance of VOC sensors are critical aspects of ensuring their long-term performance and reliability.

Calibration is the process of adjusting the sensor's output to match a known concentration of the target VOC. This is typically done by exposing the sensor to a calibration gas, which is a gas with a known concentration of the target VOC. The sensor's output is then adjusted until it matches the known concentration of the calibration gas. This process ensures that the sensor's readings are accurate and consistent.

Calibration should be performed regularly to account for sensor drift and other factors that can affect the sensor's performance over time. The frequency of calibration can depend on several factors, including the type of sensor, the specific application, and the environmental conditions. For example, sensors used in harsh environments or in applications where high accuracy is required may need to be calibrated more frequently.

Maintenance of VOC sensors can involve several activities, including cleaning the sensor surface, replacing worn-out parts, and checking the sensor's electrical connections. For instance, in MOS sensors, the metal oxide layer may need to be replaced if it becomes degraded or contaminated. In PIDs, the UV lamp may need to be replaced after a certain period of use.

Regular maintenance can help to prevent sensor failures, extend the sensor's lifespan, and ensure that the sensor continues to provide accurate and reliable measurements. It is important to follow the manufacturer's recommendations for maintenance and to use only approved parts and procedures to avoid damaging the sensor or affecting its performance.

In addition to regular calibration and maintenance, it is also important to monitor the sensor's performance and to take corrective action if any issues are detected. This can involve checking the sensor's output for any unusual or unexpected readings, performing diagnostic tests to identify any potential issues, and taking corrective action to resolve any identified issues. This proactive approach to sensor management can help to ensure that the sensor continues to perform effectively and reliably over its entire lifespan.

Applications of VOC Sensors

VOC sensors find use in a wide range of applications, each with its unique requirements and challenges.

Indoor Air Quality Monitoring

Indoor air quality monitoring is one of the primary applications of VOC sensors. Indoor air can contain a variety of VOCs, originating from sources such as building materials, furniture, cleaning products, and electronic devices. These VOCs can have a significant impact on indoor air quality and can pose health risks if present in high concentrations.

VOC sensors used in indoor air quality monitoring need to be sensitive to a wide range of VOCs, as the composition of indoor air can vary greatly depending on the specific environment. They also need to be capable of detecting low concentrations of VOCs, as even low levels of VOCs can have health impacts over long periods of exposure.

In addition to their sensitivity and selectivity, VOC sensors used in indoor air quality monitoring also need to be compact, low power, and cost-effective, as they are often integrated into consumer devices such as air purifiers, HVAC systems, and smart home devices.

One example of the use of VOC sensors in indoor air quality monitoring is in smart home devices. These devices can continuously monitor the indoor air quality and provide real-time feedback to the user. If high levels of VOCs are detected, the device can alert the user or automatically activate an air purifier or ventilation system to improve the air quality.

Another example is in office buildings and other commercial spaces, where VOC sensors can be used to monitor the indoor air quality and ensure a healthy and productive work environment. By continuously monitoring the air quality, building managers can take proactive measures to improve the indoor air quality, such as increasing ventilation or removing sources of VOCs. This can help to improve the health and well-being of the building occupants and can also contribute to increased productivity and reduced sick leave.

Industrial Emissions Monitoring

Industrial emissions monitoring is another key application of VOC sensors. Industries such as petrochemicals, manufacturing, and waste treatment can emit a variety of VOCs as part of their processes. These emissions can have significant environmental impacts and can also pose health risks to workers and nearby communities.

VOC sensors used in industrial emissions monitoring need to be highly sensitive and selective, as they need to detect and quantify specific VOCs in the presence of a complex mixture of gases. They also need to be robust and reliable, as they are often used in harsh industrial environments where they may be exposed to high temperatures, high humidity, and corrosive gases.

In addition to these performance requirements, VOC sensors used in industrial emissions monitoring also need to meet regulatory requirements. Many countries have regulations that require industries to monitor and control their VOC emissions, and the sensors used for this purpose need to meet certain accuracy and reliability standards.

One example of the use of VOC sensors in industrial emissions monitoring is in the petrochemical industry. Petrochemical plants can emit a variety of VOCs, including benzene, toluene, and xylene. VOC sensors can be used to continuously monitor the concentrations of these VOCs in the plant's emissions, allowing the plant operators to identify and address any emissions issues in real time.

Another example is in the waste treatment industry, where VOC sensors can be used to monitor the emissions from waste treatment processes. This can help to ensure that the waste treatment process is operating effectively and that any VOC emissions are within acceptable limits.

In both of these examples, the use of VOC sensors can help to reduce the environmental impact of industrial activities, protect the health and safety of workers and nearby communities, and ensure compliance with environmental regulations.

Environmental Monitoring

Environmental monitoring is a crucial application of VOC sensors. VOCs are prevalent in the environment, originating from both natural sources, such as plants and wildfires, and anthropogenic sources, such as vehicle exhaust and industrial emissions. These VOCs can contribute to air pollution and climate change and can also have direct health impacts.

VOC sensors used in environmental monitoring need to be highly sensitive, as they often need to detect low concentrations of VOCs in ambient air. They also need to be selective, as ambient air can contain a wide range of VOCs and other gases. In addition, these sensors need to be robust and reliable, as they are often used in outdoor environments where they can be exposed to varying weather conditions and other environmental factors.

One example of the use of VOC sensors in environmental monitoring is in air quality monitoring networks. These networks, which are often operated by government agencies, use VOC sensors to continuously monitor the air quality in urban areas, industrial zones, and other locations. The data collected by these sensors can be used to track air quality trends, identify pollution hotspots, and inform air quality management strategies.

Another example is in climate research, where VOC sensors can be used to measure the concentrations of VOCs in the atmosphere. These measurements can help to improve our understanding of the role of VOCs in atmospheric chemistry and climate change. For instance, some VOCs can react with other gases in the atmosphere to form ozone and particulate matter, which are key components of air pollution and can also influence the climate.

In both of these examples, the use of VOC sensors can provide valuable data that can inform efforts to protect the environment and public health. Whether it's tracking air quality in urban areas or studying the role of VOCs in climate change, VOC sensors play a crucial role in our efforts to understand and manage our impact on the environment.

Conclusion

VOC sensors play a critical role in various applications, including indoor air quality monitoring, industrial emissions monitoring, and environmental monitoring. Their ability to detect and quantify VOCs makes them invaluable tools in efforts to protect public health, manage industrial processes, and understand our impact on the environment. However, the performance of VOC sensors can be affected by factors such as sensor drift and contamination, making regular calibration and maintenance essential. Ongoing research and development are focused on improving the performance and reliability of VOC sensors, with the aim of developing sensors that are more sensitive, selective, robust, and resistant to drift.

Read about how how electronic noses are equipped with an array of chemical sensors that produce electrical signals when they encounter airborne molecules, known as Volatile Organic Compounds (VOCs) here.