Unique 3D vision technology for high-throughput plant phenotyping

Plant phenotyping has reached a new level! Wageningen University & Research developed a novel technology to determine the size, shape, color, and overall architecture of plants in milliseconds, using Photoneo MotionCam-3D & 3D Instant Meshing SW.

High-throughput plant phenotyping with novel 3D vision

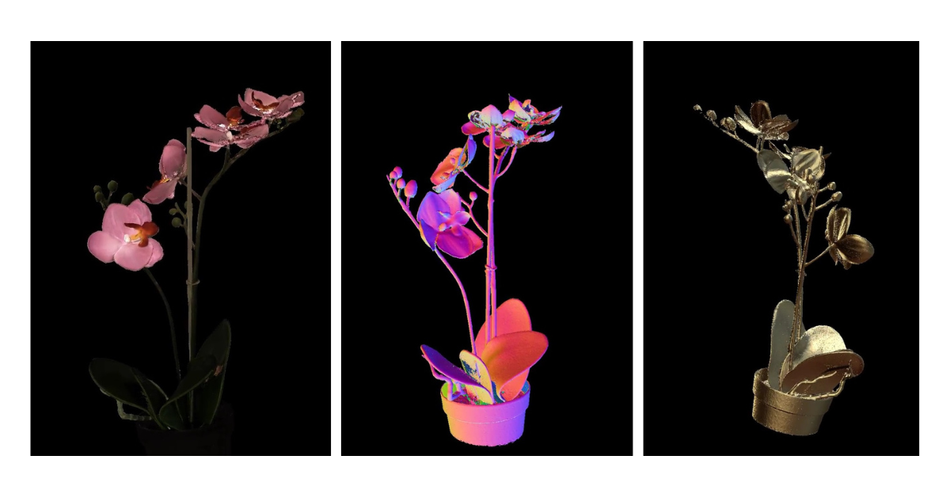

Wageningen University & Research developed MARVIN technology for high-speed plant phenotyping, seedling sorting, and other bulk quality assessment and sorting applications for the agricultural sector. For fast and high-quality scanning and 3D model creation of plants, they use Photoneo 3D camera MotionCam-3D Color and 3D Instant Meshing software. The combination of these two technologies enables fast and high-detail 3D model creation in motion, providing 3D data, color, and texture of plants at an exceptional speed.

Partner:

Wageningen University & Research

Challenge:

Wageningen University & Research has a fully automated greenhouse where they screen large amounts of plants for shape and color characteristics. For this, they developed MARVIN Gen2 – a high-throughput plant phenotyping device that generates 3D models of plants and accurately determines the size and shape of their leaves and stems plus the overall architecture in milliseconds.

Until recently, they used a machine vision solution that could only scan certain types of plants. To solve this challenge, they decided to use Photoneo MotionCam-3D Color, which can provide 3D models in higher resolution and with color information.

Solution:

MotionCam-3D Color + 3D Instant Meshing

The solution uses multiple MotionCam-3Ds attached to a robotic arm, which can rotate 360 degrees around a plant. The cameras can also move up/down and be angled in different directions. This enables our partner to scan both small plants, such as young cabbage plants, as well as taller, flowering orchid plants.

The solution uses MotionCam-3D model S to capture as many details of small plants as possible. In contrast to a 3D scanner, which constantly needs to stop to take 3D scans, MotionCam-3D can slowly rotate around the plant at a constant speed, which saves time.

The key part of the solution is the construction of 3D models based on multi-angle scans from multiple MotionCam-3Ds. Photoneo 3D Instant Meshing software enables fast, high-detail 3D model creation in motion with texture and color.

3D Instant Meshing is part of Photoneo 3D Meshing solution. It brings a big shift to 3D model creation as it enables users to create 3D models from a continuous stream of 3D scans taken by MotionCam-3D Color.

The flexibility of the MARVIN system makes it easy to set it up and recalibrate. All plant species are different, which requires different camera angles to create a good 3D model. The setup makes it possible to scan both small as well as big plants.

Discussion:

Higher quality 3D models enable users to extract more accurate information from the models. This enables the tracking of the growth of plants over time. It provides deeper insights and thorough understanding of plant development over time, which will result in a boost in data-driven plant science.

Note: This application has been developed for greenhouse use, where the effects of wind and sun are minimal.

Would you like to discuss your use case with Photoneo? Contact them here.