Understanding the Connector Landscape: Types and Design Trade-offs

This article outlines the main connector types used in electronic systems and the design trade-offs engineers must consider when selecting them.

Why Connectors Matter More Than Ever?

In the architecture of modern electronic systems, active components like integrated circuits (ICs) and complex printed circuit boards (PCBs) are mostly discussed in conversation regarding innovation. These elements are valued for their processing power and logic capabilities. However, the reliability and performance of electronic systems are also dependent on the electromechanical interfaces that connect them. Connectors quietly define the operational limits of system performance, durability, and manufacturability, and serve as the interfaces for signal and power transfer.

Industrial trends are raising the importance of connector selection. For instance, miniaturization is enabling higher functionality in smaller form factors, requiring connectors to support greater contact density without compromising performance. This requires design considerations like signal integrity, heat dissipation, and mechanical retention. Similarly, modular design approaches are becoming more common, enabling faster development cycles and easier customization but increasing reliance on robust, repeatable interconnections.

Another factor influencing connector design and selection is ruggedness without excessive weight. Portable equipment, industrial systems, and mission-critical applications all require connectors that can withstand mechanical stress, vibration, and environmental conditions. Supply chain considerations, including availability of specific materials, lead times, and the need for stable sourcing during long product lifecycles, also influence connector choices.

This article aims to map the broader connector landscape, outline common connector types, and explore the key design trade-offs engineers must evaluate when selecting interconnect solutions.

The Connector Landscape at a Glance

Connectors provide detachable, repeatable interfaces between electrical and mechanical subsystems. They allow systems to be assembled, serviced, upgraded, and modularized without redesigning the underlying hardware, in contrast to permanent interconnects such as solder joints or welded terminals.

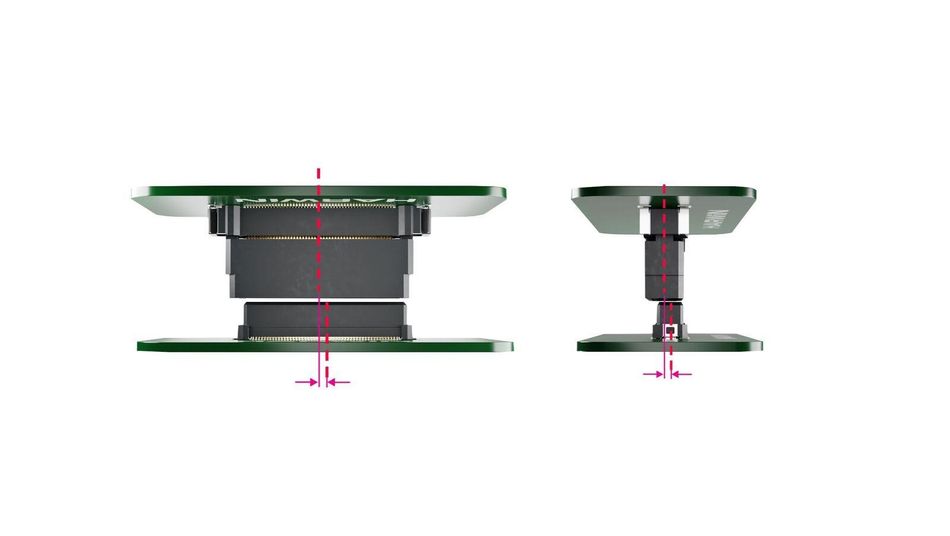

Connectors can be classified into different categories based on how and where they interface within a system. For instance, board-to-board and wire-to-board connectors are used in compact electronics to link PCBs or connect external wiring to internal circuitry, supporting dense layouts and layered system architectures. Cable connectors act as the bridge between subsystems or external equipment and are common in industrial automation, automotive harnesses, and medical devices requiring flexibility and routing freedom.

Similarly, RF and microwave connectors are designed to maintain controlled impedance and minimize signal loss at higher frequencies, supporting reliable operation in communication, sensing, and radar systems. In contrast, power connectors are optimized to distribute electrical energy safely and efficiently, often prioritizing current capacity and secure mating over signal density. Circular and rectangular connectors, on the other hand, represent form factors rather than specific electrical functions. Each form factor offers distinct advantages in sealing, contact arrangement, and mechanical locking, which is why both are found across multiple industries.

Industry-specific requirements influence which connector categories are selected. For instance, electric vehicle systems usually require high-voltage capability, thermal stability, and compact power distribution. Industrial and embedded systems often prioritize ruggedness, electromagnetic interference control, and consistent performance over many mating cycles. Similarly, aerospace and medical applications introduce additional constraints related to size, weight, and assumptions about acceptable risk and redundancy.

Design Trade-Offs and Selection Criteria

Connector selection involves several trade-offs. Engineers balance competing constraints, where improving one parameter can introduce limitations on another. Understanding these trade-offs early in the design process helps avoid downstream issues related to reliability, manufacturability, and long-term performance.

Size vs. Current-Carrying Capacity

In compact devices, connectors are expected to deliver the same or higher power levels within a smaller footprint. Reducing pin size and spacing increases resistance and limits heat dissipation, potentially constraining the allowable current. Therefore, designers should consider not only nominal current ratings but also thermal rise under real operating conditions, particularly in densely packed assemblies with limited airflow.

Weight vs. Robustness

Weight reduction is a primary need in aerospace, portable instrumentation, and wearables applications. However, lighter housings and thinner contacts can reduce mechanical strength and tolerance to handling or misalignment. Engineers usually have to decide where robustness can be selectively reduced without compromising functional reliability.

Contact Density vs. Reliability

Higher contact density enables greater functionality and reduces the connector count, simplifying system architecture. At the same time, a tighter pitch increases sensitivity to contamination, misalignment, and manufacturing tolerances. Concentrating more contacts into a smaller area increases the impact of individual contact failures. Therefore, consistent contact force and alignment are also important considerations when selecting the connector.

Mating Cycles and Durability

Not all connectors are designed for repeated use. Some are optimized for permanent or semi-permanent connections, and some are expected to withstand thousands of mating cycles without degradation. Contact wear, loss of spring force, and surface damage accumulate over time, so expected mating frequency directly impacts connector selection, especially in test equipment and modular systems.

Material Choices

Material selection affects electrical performance, as well as mechanical stability. Contact materials should balance conductivity with resistance to wear and corrosion. Housing materials influence strength, weight, and dimensional stability. Shielding materials also contribute to signal integrity and noise suppression.

Ease of Assembly and Maintenance

Connector design influences how easily a product can be assembled, inspected, and serviced. Features such as polarization, tactile feedback during mating, and tolerance to handling errors reduce assembly time and risk. From a lifecycle perspective, connectors that simplify replacement or reconfiguration can lower maintenance costs and improve overall system uptime.

Environmental and Application Constraints

The operating environment significantly impacts connector design. In aerospace and automotive systems, vibration and shock are constant considerations. Connectors used in such applications are expected to maintain contact integrity under dynamic loads without fretting or loosening. Locking mechanisms, contact spring forces, and housing stiffness are all influenced by these requirements.

Medical applications introduce different constraints as medical devices may need to withstand repeated sterilization cycles, exposure to cleaning agents, or contact with biological materials. In such cases, material compatibility and surface finishes become central to connector selection. Designers also consider patient safety and regulatory expectations. Moreover, materials in patient-contact or near-patient applications should meet biocompatibility requirements.

Industrial and defense systems are often exposed to extreme temperatures, humidity, dust, or chemical agents. Connectors used in these environments mostly require sealing solutions to prevent ingress and materials that maintain performance across wide temperature ranges. High-speed, sensitive electronics further increase complexity due to electromagnetic interference and compatibility requirements. Poorly chosen connectors can become sources of noise or signal degradation.

These environmental constraints show the importance of material engineering, including metallization processes and contact plating strategies. Such considerations determine whether a connector performs consistently over its intended lifespan or becomes a point of failure.

The Role of Standards and Compliance

Connector selection is dictated by rigorous regulatory, safety, and industry standards. Industry and regulatory frameworks such as EN9100D/AS9100D define structured requirements for quality management, traceability, documentation, and process control. Connector choices should align not only with functional needs but also with the certification expectations of the overall system.

Standards are necessary for ensuring interoperability across complex supply chains. They define common expectations for performance, testing, and manufacturing discipline, reducing uncertainty when components are sourced from multiple vendors or integrated into larger platforms.

Manufacturers such as Harwin develop a broad range of connector types intended for use across different applications while adhering to relevant standards. For instance, Harwin’s connector families adhere to EN9100D / AS9100D globally recognized quality management system (QMS) standard for the aviation and defense industries. This allows designers to select components that align with both technical requirements and compliance obligations. Standards also contribute to supply-chain predictability, which is critical for long-lifecycle products in aerospace, defense, and regulated medical markets.

Looking Ahead - From Fundamentals to Innovation

Connectors are designed around trade-offs in size, weight, power handling, materials, and environmental conditions. A clear understanding of the connector trade-offs enables engineers to balance these factors early in the design process. This helps avoid redesign cycles, improves overall system reliability, and simplifies integration with other components.

In this sense, connector choice carries the same weight as decisions made about active electronic components. It influences how reliably power and data move through a system, how easily that system can be assembled or serviced, and how well it performs over its intended lifetime. Engineers looking to explore connector solutions designed with these trade-offs in mind can find additional technical resources and application-focused options on Harwin’s website.

References

1. Harwin. [Online] Available at: https://www.harwin.com/ (Accessed on December 10, 2025)

2. Harwin. [Online] Wevolver. Available at: https://www.wevolver.com/profile/harwin (Accessed on December 10, 2025)

3. Types Of Electrical Connectors. [Online] Connector Supplier. Available at: https://connectorsupplier.com/connector-basics-three-types-of-electrical-connectors/ (Accessed on December 10, 2025)