Simulation-Driven Design: The Secret to Better Products in Less Time

Article #1 of our simulation series. Simulation tools improve the development process, enabling engineers to deliver better products in less time.

Innovation in product-development is a demanding task. Engineering teams across all industries are continuously facing the challenge to create innovative and increasingly complex products while meeting all kinds of requirements such as target costs, time constraints, regulatory requirements, and improved product performance.

In today's fast-moving world, these requirements are constantly evolving. Fortunately, there is a solution to overcome these engineering challenges, CAE (Computer Aided Engineering) tools. These tools facilitate computerized simulations that can solve all kinds of engineering challenges and help product developers achieve their design goals while reducing costs and time-to-market.

Why use simulation?

Simulation is not a new method. Thousands of engineers and companies have been using various simulation tools to improve their development processes and products for many years. However, for many others, simulation is not leveraged due to implementation costs and efforts or lack of human resources. These engineers and companies have not yet realized that CAE tools can help them develop innovative products while reducing costs and development cycles at the same time. This article demonstrates the benefits of simulation and virtual development processes using two real-life case studies.

The value of a comprehensive simulation-driven design approach is made clear by showing how the modeling and prediction of part behavior can be produced more accurately, as model features and fidelity can be modified to fit the needs of a particular analysis. By importing CAD into CAE-centric analysis software, the user gains more control over the accuracy and speed of analysis.

Examples of a successful implementation of simulation-driven design

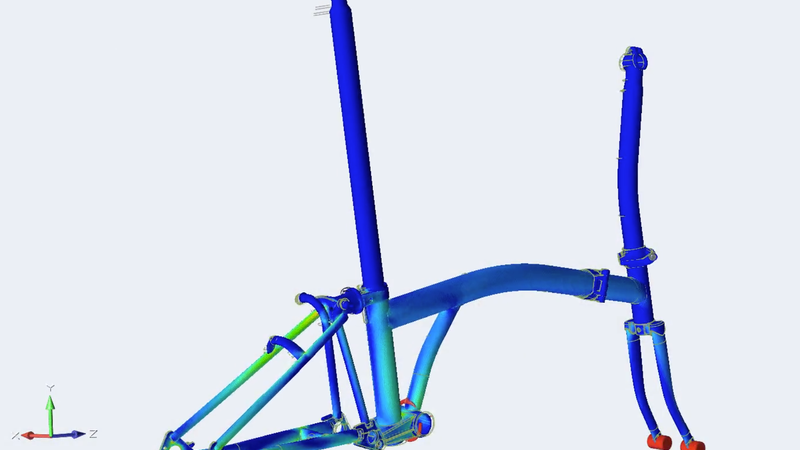

There are countless examples of engineers seeing tangible results in their design process and quality after integrating simulation. Many designers who were using CAD integrated simulation features realized at a certain point that these native tools were not sufficient for what they wanted to achieve. Iconic bike manufacturer Brompton Bike is an excellent example of this.

The Brompton team started with a CAD solution but at one point realized that this would not be sufficient for their needs. Jonathan Heath, Lead Mechanical Engineer Brompton Bicycle describes the evolution to using advanced simulation tools:

"The step we made was moving from an embedded FE system within CAD, which has huge limitations. It had a purpose. But we outgrew that purpose. And moving to a specialized simulation software package gives a more comprehensive FE system - greater flexibility - greater breadth. And that's opened up the mindset, not just of the design engineers, but of management and how we can use this tool on design problems we never really knew we had. We know where the failures are likely to be if we're going to see failures before we start the test cycle. And that improves the design robustness and allows us to move to the next development cycle quickly and with more understanding of the design."

The use cases for a simulation-driven design process are not limited to the bike industry. Similar stories can be found from small startup companies to world-leading providers of passenger transport systems (skiing lifts) such as Doppelmayr. With the application of specialized simulation tools to their development processes, the Doppelmayr engineers were able to increase the lifetime of a seam weld while reducing the length of each component's weld seam by 3.5 meters. In addition to that Doppelmayr also reduced manufacturing time and costs by approximately 10% for the new design.

Other examples come from industrial machinery, heavy equipment, or medical devices. What they all have in common, is that at a certain point in time they had to start applying simulation into their processes, to get products faster to market, increase product quality or performance, or make their products lighter.

As shown in the examples above, increasing innovation, product performance, and customer satisfaction can go hand in hand with reducing development time, manufacturing risks, and overall development costs. CAE tools offer multiple opportunities to drive the development of innovative products from the first concept up to series production.

Linking test, design, and simulation and the implementation of a simulation-driven design process right from the start of a project can tremendously streamline the entire process and thus foster innovation - providing all industries and companies relying on simulation with the most valuable assets of all: the competitive edge to stay ahead in innovative product development and satisfied customers.

Whether you are completely new to simulation or looking to expand your capabilities, the free one-day virtual event, Don't be Late to Simulate, on November 30 is a great way to expand your knowledge. Learn more about using simulation for more efficient and effective product design, hear from startups who are using simulation in their design process and take part in hands-on workshops. Learn more about the event here.

How to apply simulation efficiently with Altair

Altair is one of the leading simulation software providers, they offer solutions to help engineers make the first step to incorporating simulation into their design process.

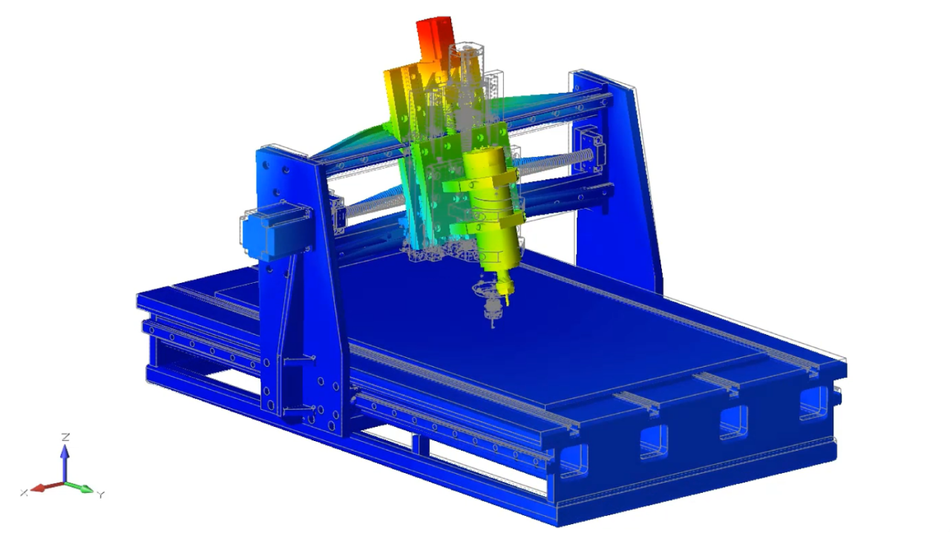

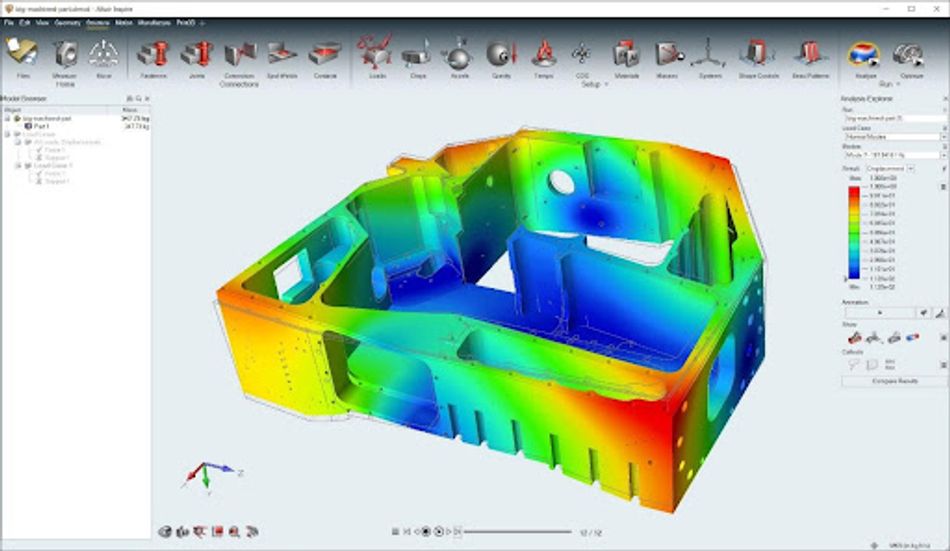

Altair Inspire™ provides intuitive surface modeling and geometry modification tools to help users prepare models for analysis at the fidelity that best suits the analysis detail and solver performance needed at that stage of the development process. This ensures that iteration and comparative studies are possible in early-stage design while offering the flexibility to model at higher fidelity for performance validation and detailed physics assessments.

Altair SimSolid™, is a solver available within the Altair Inspire product. Users can import intricate CAD geometries and assemblies, including connections, contacts, welds, detailed dimensions and angles, and more without model simplification or modification. This solver produces results in seconds to minutes, enabling multiple concepts to be assessed in less time than one typical CAD-based simulation run, shortening the design cycle while increasing the insight into the product's behavior.

Altair SimLab™ offers more detailed multiphysics analyses, including structural, thermal, and fluid dynamics. It has an intuitive user interface that enables geometry to be imported and updated via the bi-directional CAD coupling.

All of these tools are straightforward to learn and can be implemented in whatever your design and development process currently is. Interfacing with all common CAD and CAE tools, Altair offers also a flexible licensing scheme so you can step up your use of simulation without unnecessary investment.

This is the first of five articles in a series about simulation tools sponsored by Altair. Future articles will cover case studies on using simulation in product design, cover workshops on how to get started with advanced simulation software, and explore the applications of multiphysics simulation.

Altair is hosting the free virtual global event, Don't Be Late to Simulate on November 30, 2021: 2:00 p.m. (Paris) and at 8:00 a.m. (New York).

If you are interested in moving from CAD-based simulation to a more robust solution or if you have looking to expand your capabilities, this free to attend virtual event offers a mix of keynotes, case studies, and workshops to help you to be more efficient and effective in how you develop new products.

Article #2 demonstrates why CAD-based Simulation Can Become a Game of Cat and Mouse.

Article #3 is for advanced simulation tools that helped this German startup design a press machine that plays a role in reducing carbon emissions.

Article #4 previews a workshop that will take place at the Don’t be Late to Simulate event on November 30.

Article #5 speaks for the advances in software and increased access to inexpensive compute power means more and more engineers can use Multiphysics analysis to improve their design processes.

About the sponsor: Altair

Altair is a global technology company, which provides software and cloud solutions in the areas of simulation, high-performance computing (HPC), and artificial intelligence (AI). Altair enables organizations in nearly every industry to compete more effectively in a connected world while creating a more sustainable future. Wherever you are and whatever you’re doing, Altair’s solutions surround you – keeping you safer, more connected, and more productive. They can be found in big places and small — on highways, hospitals, and hockey rinks, in stadiums, skyscrapers, and subways, and in banks, bikes, and boats.