'Should Costing' and Why It Doesn't Work for Custom Parts

FACTUREE's innovative costing methods result in an average reduction of procurement expenses by 37%. Learn more about how to streamline your custom manufacturing processes with their solutions.

Accurately forecasting procurement costs is essential for maintaining efficiency and competitiveness in manufacturing. Historically, cost estimation methods like “Should Costing” have been widely adopted across industries to predict the expenses associated with production. However, in today’s more dynamic market where custom parts are becoming increasingly important, the limitations of “Should Costing” are being exposed. This article explores why “Should Costing” falls short and how FACTUREE’s AI-driven costing approach offers a powerful new alternative.

| ℹ️ | Did you know that should costing has its roots in the U.S. Department of Defense? It was developed to help procurement officers determine fair and reasonable pricing for military equipment and services. Today, this practice has been adopted by various industries to optimize costs and enhance supplier negotiations. |

Understanding “Should Costing”

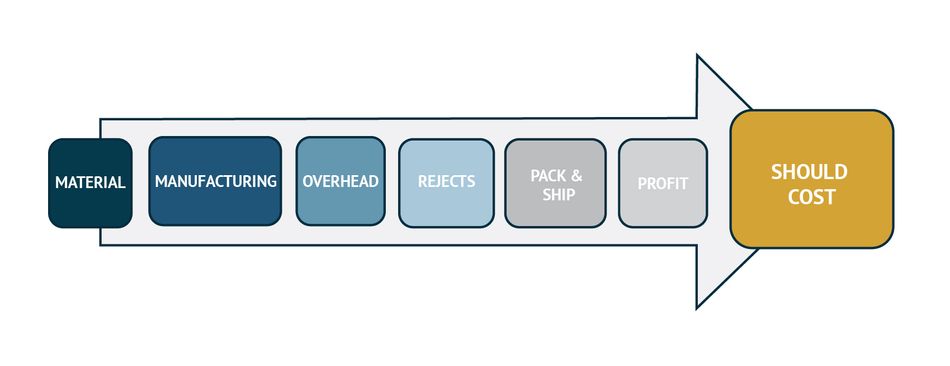

“Should Costing” is a cost analysis methodology aimed at determining the “ideal” cost of manufacturing a product [1]. Specifically, it evaluates costs based on theoretical calculations of material expenses, labor requirements, and production overhead. The method assumes that by understanding these factors, procurement teams can negotiate better prices with suppliers or identify cost-saving opportunities.

While “Should Costing” provides a structured framework for estimating costs, it relies heavily on assumptions, including static labor costs, standard material prices, and predictable production capabilities. For off-the-shelf components, where parameters are consistent, “Should Costing” can be moderately effective. However, custom parts—which are designed for specific applications and often involve unique geometries, materials, and processes—render this methodology unreliable.

Challenges in Applying “Should Costing” to Custom Parts

Custom parts introduce a level of complexity that “Should Costing” cannot effectively address. This complexity arises from factors such as:

- Unique Design Requirements: Custom parts often feature non-standard geometries and design specifications that deviate from typical manufacturing norms. These features may require specialized tools, additional production steps, or unique materials.

- Material Variability: Raw material costs can fluctuate significantly based on market conditions, supplier availability, and required specifications (e.g., purity, strength, or thermal properties). “Should Costing” struggles to account for such variability.

- Process Complexity: Manufacturing custom parts may involve niche techniques like advanced CNC machining, additive manufacturing, or surface treatments. These processes introduce costs that are difficult to predict using “Should Costing” assumptions.

- Supplier Capabilities: Supplier-specific factors such as equipment capabilities, production schedules, and compliance with industry standards play a significant role in determining costs. “Should Costing” often overlooks these nuances.

Ultimately, by relying on idealized cost projections, “Should Costing” can lead to inaccurate estimates. This can cause procurement teams to negotiate based on unrealistic expectations or select suppliers ill-suited to meet the actual production requirements. The consequences include higher-than-expected product costs, delays in delivery, and compromised product quality.

FACTUREE’s Approach: Best Costing (Powered by AI)

Recognizing the shortcomings of traditional costing models, FACTUREE developed a “Best Costing” approach—a predictive, data-driven methodology designed to address the unique challenges of custom part procurement. At the heart of this model lies artificial intelligence (AI) and a robust database of supplier information to enable precise and market-aligned cost forecasts.

FACTUREE’s AI analyzes a wide range of parameters, including part geometry, material properties, supplier production capacities, logistics and delivery timelines, and compliance and auditing requirements. To this end, the model leverages over 600,000 data points per supplier, covering factors like pricing trends, manufacturing capabilities, and historical performance.

With such comprehensive data analysis, FACTUREE’s approach ensures that predictions are grounded in actual market dynamics rather than speculative assumptions. And, with an accuracy rate exceeding 90 percent, FACTUREE’s AI can tackle even the most complex interactions between design, materials, and manufacturing processes.

Importantly, custom part designs are processed anonymously to safeguard intellectual property and minimize the need to share sensitive information with multiple suppliers. A key benefit of the data-driven approach is that it not only streamlines the selection process but also enhances security by limiting the number of potential manufacturing partners that need to be contacted, thereby minimizing exposure and risk

Advantages of the “Best Costing” Approach

The benefits of FACTUREE’s “Best Costing” approach extend beyond accurate pricing. Major advantages include

Cost Savings: On average, FACTUREE can generate savings of 37% in procurement and overhead costs.

Optimized Supplier Selection: By matching parts to suppliers with the right capabilities, the approach enables efficient and cost-effective production.

Reduced Time-to-Market: Automated processes and precise cost forecasts streamline decision-making to accelerate the procurement cycle.

Supply Chain Resilience: The model’s data-driven insights enable manufacturers to respond flexibly to market changes and mitigate supply chain risks.

Get started with Facturee here.

Digitalization in Procurement

FACTUREE integrates its methodology into a centralized digital procurement platform, which digitizes and automates key processes like supplier selection, manufacturing coordination, and post-production services. The platform simplifies procurement by handling all aspects of supplier engagement, from initial consultations to final delivery, effectively eliminating the need for buyers to manage multiple vendors.

As a result of the platform, customers achieve real-time visibility into production timelines and enhanced process transparency, attributes directly facilitated by a designated liaison who is explicitly available to each customer for technical support and queries.

The platform also accommodates a breadth of manufacturing methods, including CNC machining, sheet metal processing, 3D printing, casting, and surface finishing, making it versatile enough for diverse custom part requirements. Read about the full list of services here.

FACTUREE’s procurement model provides substantial advantages in managing supply chains efficiently. Through predictive analytics, manufacturers can swiftly adapt to changes in demand or material availability. The platform mitigates reliance on individual vendors via its extensive supplier network, thus maintaining production continuity. Centralized data and communication tools streamline coordination between stakeholders, enhancing operational efficiency. Importantly, FACTUREE acts as the sole intermediary: customers and manufacturers communicate only with FACTUREE, not each other. They manage the entire process, significantly reducing stress and complexity for their clients. As the exclusive contractual partner, they coordinate all aspects, including quality control. When a customer registers FACTUREE in their system, they gain access to a network of over 2000 potential partners, simplifying their procurement process through a single point of contact

The Future of Procurement

Traditional costing methods like “Should Costing” are ill-suited to the complexities of custom part procurement. Their reliance on static assumptions and theoretical calculations exposes manufacturers to financial and operational risks. FACTUREE’s AI-driven approach provides a robust alternative that leverages real-world data to deliver accurate pricing, cost savings, and streamlined operations.

By adopting FACTUREE’s novel solutions, manufacturers can navigate the challenges of modern procurement with confidence to achieve greater efficiency and resilience. With FACTUREE, the future of procurement is not just smarter—it’s simpler, safer, and significantly more effective.

References

[1] https://www.facturee.de/en/facturee-shows-should-costing-in-procurement-is-not-cost-effective/

[2] https://www.facturee.de/en/