Revolutionizing Confined Space Inspections: A Safer, Faster, and Cost-Effective Approach

The inspection of confined spaces within the Non-Destructive Testing (NDT) industry presents numerous challenges, ranging from safety concerns to the substantial costs and extended downtime associated with traditional inspection methods.

The inspection of confined spaces within the Non-Destructive Testing (NDT) industry presents numerous challenges, ranging from safety concerns to the substantial costs and extended downtime associated with traditional inspection methods. Conventionally, these methods often entail the laborious task of setting up scaffolding, introducing not only elevated risks to inspectors but also a costly and time-consuming process that can reduce overall productivity for asset owners.

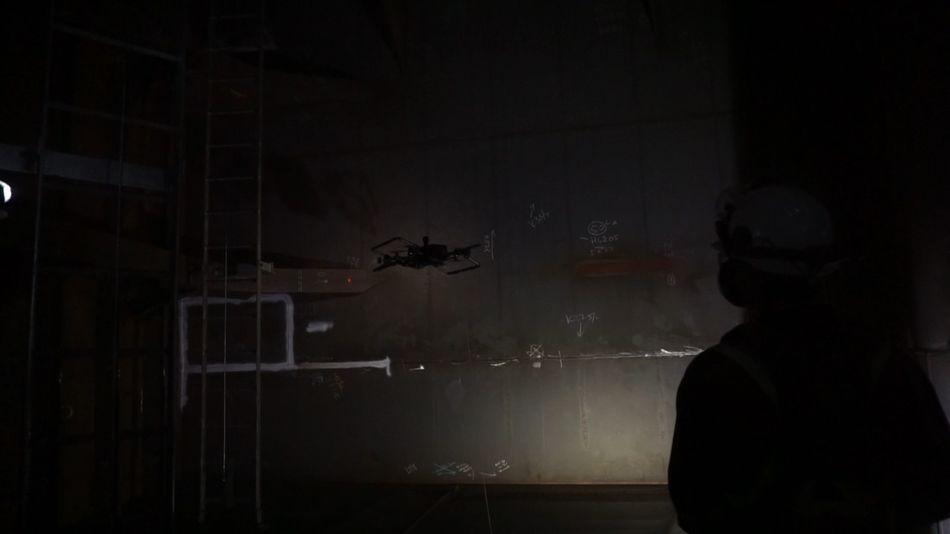

Transitioning from a human-centric model to a robotic solution is a welcomed shift for asset owners and inspection service providers, primarily due to the enhanced safety it offers. SKYRON, an intelligent flying robot, emerges as a groundbreaking solution that addresses the challenges of inspecting confined spaces head-on. The shift is primarily driven by the heightened safety benefits offered by robotic solutions compared to human inspectors facing risks of heat exhaustion and various other dangers while navigating the complexity of confined spaces.

Robotic solutions, exemplified by SKYRON, not only serve as a safety net for inspectors but also prove to be significantly more time-effective. By minimizing setup times and eliminating the need for human intervention in precarious spaces, SKYRON expedites the inspection process, completing it in a fraction of the time required by traditional methods. This not only enhances safety but also brings about a revolutionary shift in the overall efficiency of confined space inspections, allowing for more inspections to be conducted in a shorter timeframe.

SKYRON, an intelligent robot with an extensive track record of inspecting confined spaces, ranging from confined spaces in Floating Production Storage and Offloading units (FPSOs) to the interiors of flare stacks and tanks, offers a unique advantage in this domain. Its rapid deployment eliminates the need for inspectors to physically maneuver inside confined spaces, providing a layer of safety that is unparalleled.

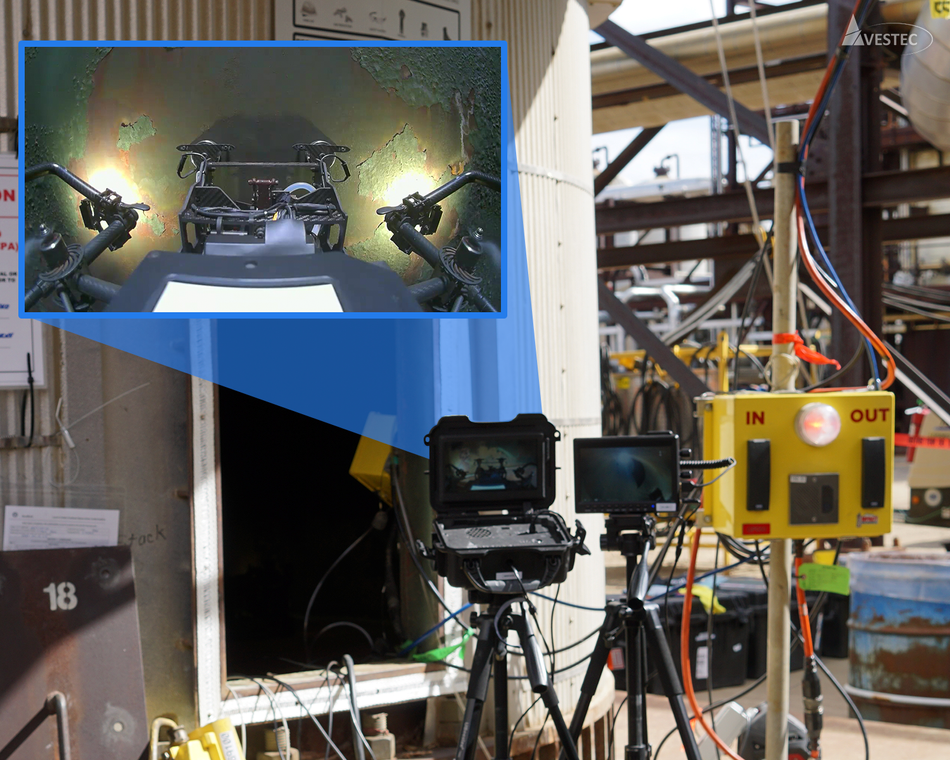

In addition to its remarkable safety features, SKYRON's standout capability lies in its non-entry Ultrasonic Thickness (UT) inspections. This crucial feature distinguishes SKYRON from other inspection methods, as it enables a thorough assessment of structural integrity without the need for human entry. Furthermore, the inclusion of a First-Person View camera empowers the pilot to operate SKYRON from a safe distance, providing real-time visual feedback. This not only ensures the safety of inspectors but also makes SKYRON an ideal solution for navigating through the tight confines of narrow spaces, where traditional inspection methods would pose significant challenges.

SKYRON's versatility extends beyond safety and efficiency through its innovative Interchangeable Payload System. This feature allows SKYRON to adapt to various inspection needs by seamlessly switching between different payloads. For instance, it can effortlessly transition from Visual inspections to Ultrasonic Thickness (UT) measurements, providing a comprehensive assessment of confined spaces. This adaptability ensures that SKYRON is not limited to a single inspection type, making it a dynamic and multifunctional tool for industries with diverse inspection requirements. The ability to tailor its payload according to specific inspection objectives enhances SKYRON's value and makes it an indispensable asset in optimizing the inspection process for different applications.

The smart tether system further contributes to the efficiency of the inspection process, ensuring unlimited fly time and eliminating the need for battery changes during inspections. This feature not only enhances the longevity of inspections but also prevents disruptions, making SKYRON an invaluable asset for continuous and uninterrupted operations.

In summary, SKYRON represents a revolutionary advancement in confined space inspections, providing a safer, faster, and more cost-effective alternative. This intelligent robotic solution effectively addresses the challenges associated with traditional methods, ensuring the well-being of inspectors and raising the efficiency of confined space inspections to unprecedented levels. As industries evolve, SKYRON stands as a beacon of innovation, reshaping the landscape of confined space inspections for a safer and more efficient future.