Rapid Tooling in Development of Automotive Interiors & Exteriors

A single automobile has about 30,000 parts, counting every part down to the smallest screws. Therefore, the process of developing an automobile would be a voluminous task, which could even take thousands of people a couple of years.

Photo by Erik Mclean on Unsplash

A single automobile has about 30,000 parts, counting every part down to the smallest screws. Therefore, the process of developing an automobile would be a voluminous task, which could even take thousands of people a couple of years. From automotive project initiation to mass production, every automotive company follows its own R&D procedures, which generally comprises market research, vehicle concept design, engineering design, prototype testing and production ramp-up.

Market Demand

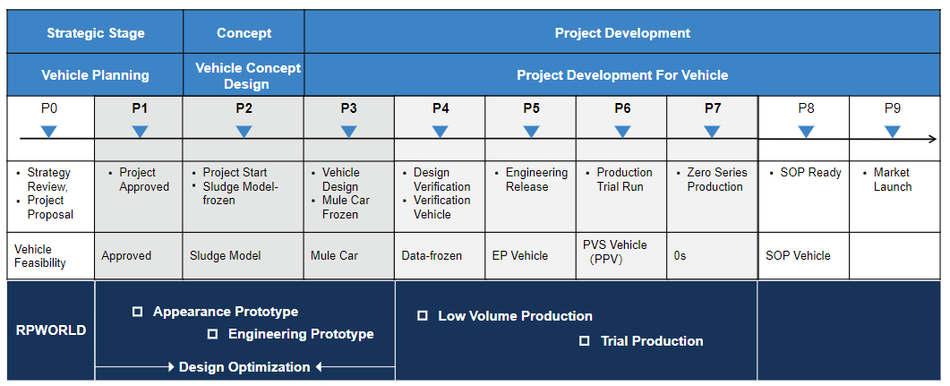

The design of interiors and exteriors as a link of automotive design, is an important part of automobile engineering data, and consists of front end, door panel, roof, instrument panel system, side trim etc. A large number of prototypes will be needed during the development process for structural testing, material testing, road testing, etc. The figure below is the R&D flowchart of an automotive company (P0-P9). RPWORLD provides rapid tooling service that applies to injection molding parts made of thermoplastic materials in chart stage P4-P7.

Rapid Tooling Introduction

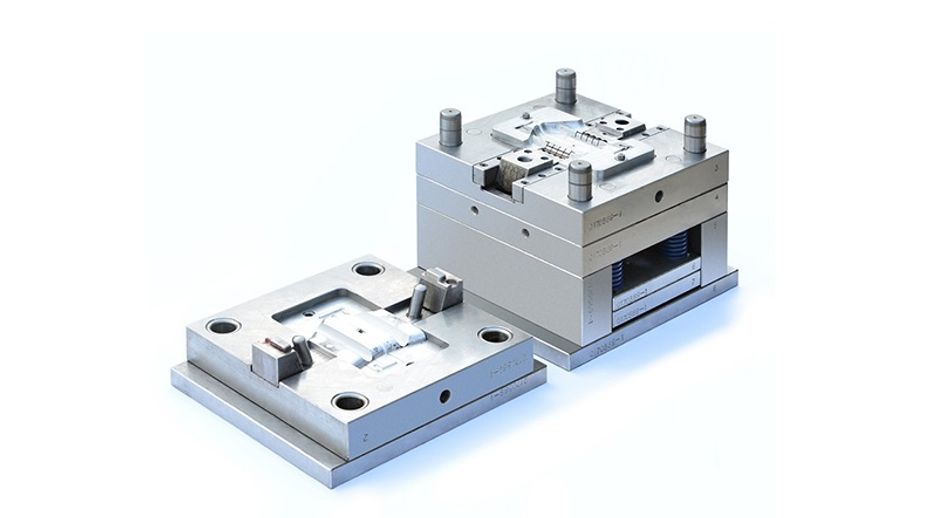

Ranging from a few parts to thousands of parts, the part quantity needed from an automobile company is varied at different development stages. Even more, most of the molds are one-off requirement, and the followings should be met: real materials (close or similar to materials used in mass production), high dimensional accuracy, and maximum reduction of 3D features. Therefore, RPWORLD launches rapid tooling service in responsive to the automotive customers’ requirements. Based on traditional tooling, RPWORLD’s rapid tooling is simplified as the following:

- Adopt cold runners, one mold for one part or multiple parts, reducing slightly the production efficiency;

- Materials of mold core is P20/#45/aluminium alloy, which will not be thermally treated, and even can be produced directly on mold base to create the one-piece part;

- Use manual inserts and sliders as much as possible, replacing automatic slider;

- Utilize the top-out system or manual demolding;

- The cooling system is designed according to the specific product and as simply and practically as possible;

- Combining with multiple processes, engineers take full advantages of each process. For example, conducting CNC machining, and manual removal of gate and burrs after injection molding process for those high precision parts; Implementing painting finishing for those parts of high-quality surface treatment.

Comparison of Rapid Tooling with Other Processes

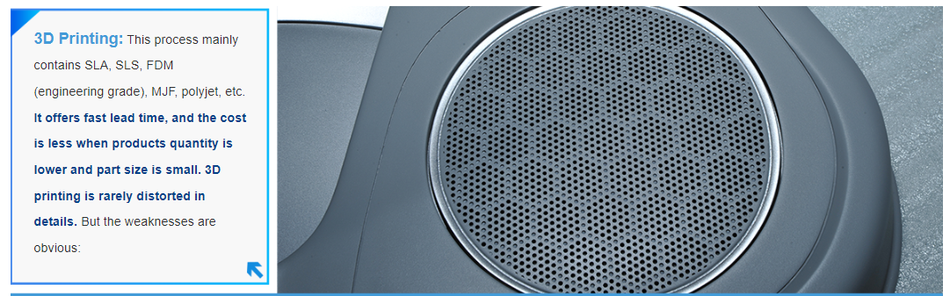

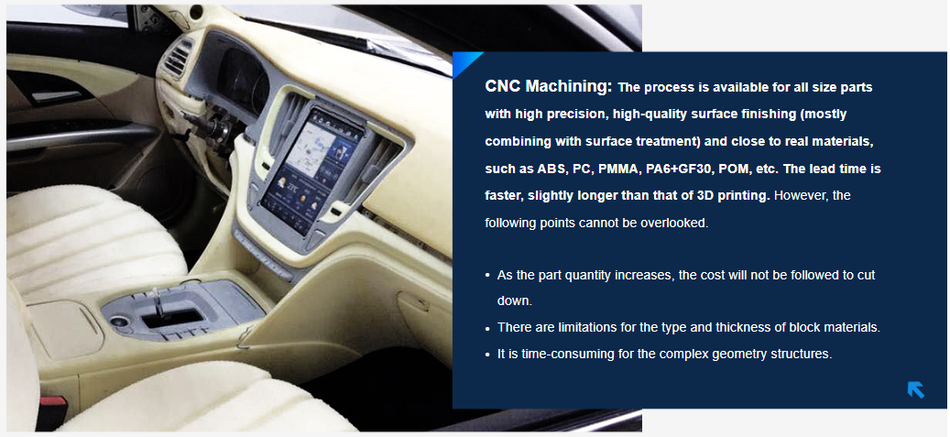

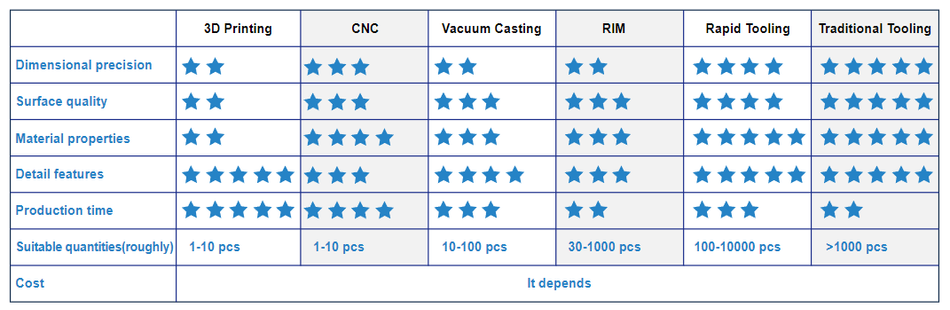

There are variety of choices of manufacturing processes for different customers and different stages of product development. In general, the processes are 3D Printing, CNC Machining, Urethane Casting, RIM, Rapid Tooling and Production Molding, etc.

- It is suitable for small size products. Because the machine for large size parts is costly and lower in parts quantity.

- The accuracy of 3D printed parts is average. Perhaps there’s severe shrinkage on dimensions, and surface quality is average. The high-quality finishing on 3D printed parts is costly.

- The material of 3D printed parts is limited. Take FDM for instance, which offers more material choice, but the material is not highly compacted and the material properties in the XYZ directions are anisotropic, resulting in a far difference in actual product performance.

Traditional Tooling: Compared with rapid tooling, the traditional tooling is more precision, better on surface quality. But it applies only for high-volume production.

Rapid Molding Application

Many international companies have launched rapid molding, which is slightly different from ours. 3D printed mold is currently popular internationally, which offers quick turnaround times, but has more restrictions. Take the ABS injection molded molds of a manufacturing supplier for instance, the lead time of mold is only one week and the cost is less, but the products are required to be small size, simple structure, lower precision and larger demolding angle (greater than 5° is recommended). The die life is within 20 times, and surface quality is poor. This type of mold is mostly applied to medical devices and instrumentation industries, only available for the application of material testing, and fast lead time should be met. It is rarely used in automotive interiors & exteriors.

There are also international companies that offer molds made of aluminum alloy. We all have the close turnaround times, but surface treatment of RPWORLD is finer than that of other companies. The reason probably is that they have made subtraction such as no water-cooling system in mold and less polishing on the mold surface. In addition, RPWORLD’s molds of aluminum alloy is more financially effective. The part of reason is that the labor costs of developed countries are higher, contributing to higher cost on their products.

RPWORLD also provides rapid tooling made of #45/P20 materials, the lead time is around 3-4 weeks, and the cost is close to aluminum alloy molds. But aluminum alloy mold is not applicable for every situation, and is not cost-effective for the products of complex geometry structure. For example, too much ribs on interiors and exteriors will cause overload for EDM; The low modulus of elasticity of aluminum alloy material makes the mold rigidity insufficient and brings problems to the injection molding production, especially for the large-size products; The poor welding performance of aluminum alloy will greatly increase the project risks if the mold is required to be modified in future.