Power Architecture for AI Data Centers: The Shift Toward HVDC Distribution

AI workloads are pushing the power demands of server racks beyond the practical limits of 48 VDC distribution. With current levels reaching several MW, data centers using traditional architectures face insurmountable power losses, making the shift toward HVDC distribution a necessity.

The AI Power Bottleneck: Why the Data Center Power Architectures Must Change

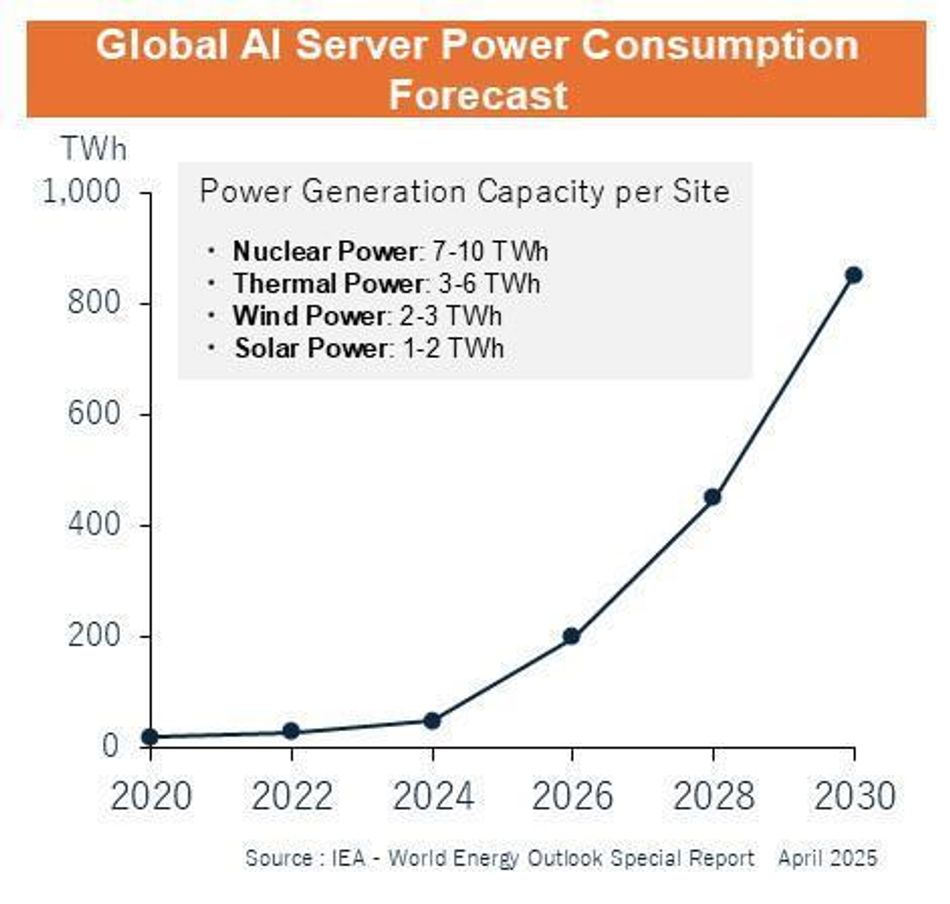

New data centers are being built around the world, with server racks being packed tightly to maximize compute per square meter.

Now, the methods for supplying power to these server racks are facing urgent reevaluation. The reason is the explosive increase in the amount of electricity consumed by a single server rack. Traditionally, power consumption of several hundred kW was the norm. However, it is predicted to reach around 1 MW by the late 2020s and around 10 MW in the not-too-distant future.

The driving force behind this surge is the expanding demand for AI processing. Graphics Processing Units (GPUs), which are essential for AI processing, consume enormous amounts of power. NVIDIA's B200 GPU, based on their Blackwell architecture, consumes up to 1200 W of power. An AI server housing dozens of these GPUs consumes dozens of times more power than conventional servers. Furthermore, as the processing power of next-generation GPUs improves, their energy consumption will continue to grow. Consequently, the power demand of AI server racks is skyrocketing.

When the power consumption of a server crosses the 1 MW mark, using the traditional 48‑volt DC (48 VDC) power supply method results in extremely large supply currents. Supplying 1 MW at 48 V requires a current of approximately 20,000 A, and at 10 MW the current reaches about 200,000 A.

With such massive currents, significant power is lost even within the power distribution wiring (busbars) as copper loss (I²R loss), which increases with the square of the current and becomes impossible to ignore as power levels rise.

For example, if the total resistance of the vertical busbars running inside a rack is assumed to be 1 mΩ, and the current splits among units along the way, the effective resistance can be approximated as about one‑third of the total. In this case, even when supplying 1 MW, the busbar losses reach roughly 130 kW, meaning more than 10% of the supplied power is lost in the wiring. At the 10 MW scale, this loss ratio could exceed 50%.

Reducing these losses requires busbars with extremely low resistance, which in turn necessitates the use of large amounts of copper. This leads to challenges not only in terms of cost and weight but also resource consumption and environmental impact, factors that pose major issues in building AI data centers.

Increase Voltage to Reduce Current: High Voltage Direct Current (HVDC) Systems Are Now Mandatory

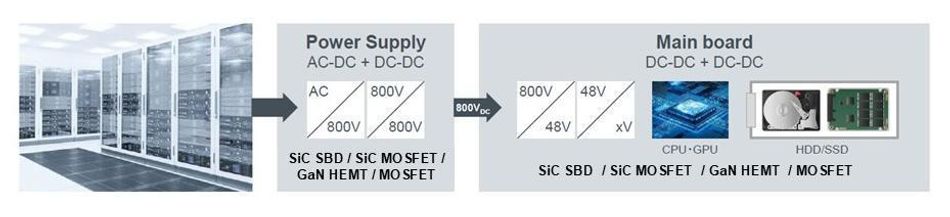

Therefore, the existing 48 VDC power supply system is no longer sufficient. A new system must be introduced. Currently, two proposed systems exist. One supplies power at +800 VDC; the other supplies power at ±400 VDC. Both fall under the category of High Voltage Direct Current (HVDC) systems.

Provided the power remains constant, raising the voltage will decrease the current. For example, if the power supplied to a server rack is 1 MW, raising the voltage to 800 V reduces the current to 1250 A. Since power loss in a busbar is proportional to the square of the current, increasing the voltage from 48 V to 800 V reduces the current by a factor of 48/800. This decreases power loss to 1/278 of its original level, enabling a significant reduction in the amount of copper required. For this reason, the adoption of HVDC is expected to accelerate in the coming years.

Leading IT infrastructure companies, primarily Big Tech, are currently accelerating their efforts to commercialize 800 VDC and ± 400 VDC systems. NVIDIA is a prime example of a company driving the 800 VDC initiative. To bring 800 VDC to practical use, the company is building an extensive ecosystem that involves semiconductor manufacturers, power supply vendors, and data center power system integrators.

On the other hand, the Open Compute Project (OCP) is the primary advocate for ±400 VDC. Founded in 2011 by Meta Platforms (formerly Facebook), OCP is a non-profit community dedicated to open-sourcing data center hardware designs for industry-wide collaboration. Companies like Meta and Google have already developed power systems for server racks that support ±400 VDC.

Comprehensive Power Semiconductor Portfolio for HVDC Systems

As power supply methods change, further optimization of power supply system/circuit configurations becomes essential. Whether 800 VDC or ±400 VDC, optimizing power supply systems/circuits is essential. For a server rack consuming 1 MW, improving conversion efficiency by just 2-3 percentage points saves 20-30 kW of power, which is a significant margin that cannot be overlooked.

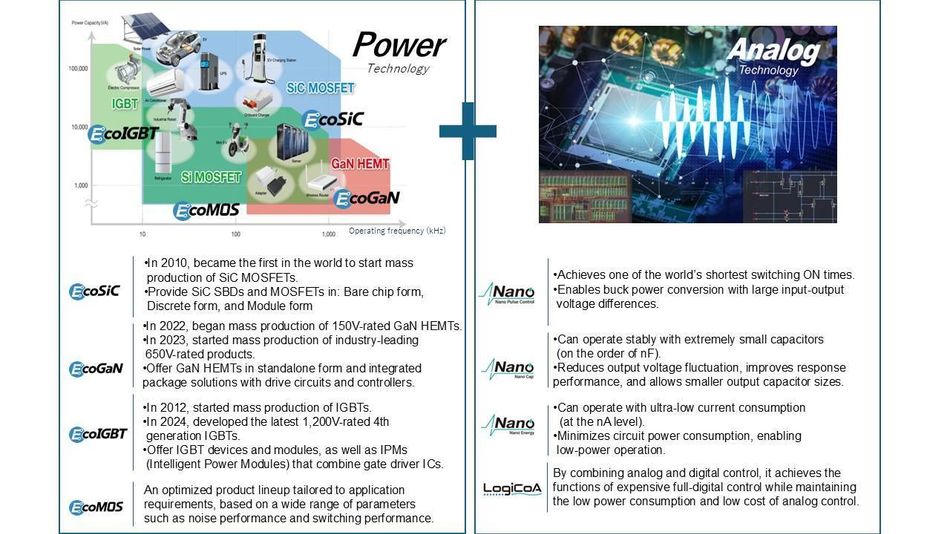

To address this, ROHM is committed to supporting power supply manufacturers and data center system integrators in their optimization efforts.

ROHM offers a comprehensive lineup that includes power semiconductors, analog ICs such as power supply control ICs and DrMOS (Driver + MOSFET), and passive components like resistors and optical semiconductors. This enables efficient optimization of power supply circuits. In practice, prototypes of power supply circuits required for 800 VDC and ±400 VDC have already been developed, achieving high efficiency and miniaturization.

ROHM has also established a strategic partnership with Germany’s Infineon Technologies.[1] Under this collaboration, both ROHM and Infineon provide SiC power MOSFETs housed in identical, standardized packages. By leading the effort to standardize power semiconductor packaging, ROHM ensures a more stable supply chain. This allows users, such as power supply manufacturers, to easily secure reliable second-source products.

Achieving High Efficiency and Increased Power Density

ROHM has already completed simulations of circuits/systems power optimized for HVDC power supplies such as 800 VDC and ±400 VDC. Here are the practical examples of the same:

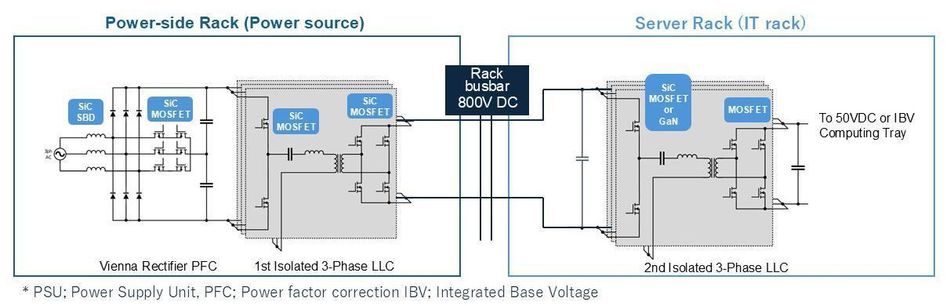

The first example is a 20 kW to 30 kW PSU designed for power-side racks. It converts a three-phase AC input of 230 V to 430 V into an 800 VDC output. In this application, achieving high power conversion efficiency is paramount.

ROHM recommends a circuit configuration that combines a Vienna rectifier with an isolated three-phase LLC resonant converter. In the Vienna rectifier, the 3rd-generation SiC Schottky barrier diodes (SCS240KE2 are used as boost diodes, while the 4th-generation SiC power MOSFETs (SCT4013 series/SCZ4008DTB) serve as the midpoint switches. Furthermore, the isolated three-phase LLC resonant converter also incorporates these 4th-generation SiC MOSFETs (SCT4013 series/SCZ4008DTB). This optimized combination achieves an outstanding conversion efficiency of approximately 99%.

The second example is a PSU for IT server racks. This circuit converts an 800 VDC input into a 50 VDC output. To fit within the limited space of a server rack, exceptionally high power density is required. ROHM offers two recommended circuit configurations for this application.

The first is an isolated three-phase LLC resonant converter. By utilizing our 4th-generation SiC power MOSFETs (SCT4018 series/SCZ4006KTA/SCZ4011KTA) on the primary side and Si power MOSFETs (RS7N200BH) on the secondary side, it is possible to achieve a power density of 7.8 W/cc at a switching frequency of 100 kHz.

The second proposal further enhances performance by splitting the 800VDC input into two parts and connecting isolated three-phase LLC resonant converters in series. By adopting GaN HEMTs (GNP2025TD) on the primary side and increasing the switching frequency to 500 kHz, the power density can be doubled to 15 W/cc. Both configurations deliver an impressive conversion efficiency of approximately 99%.

The Power Supply Architecture Required for AI-Scale Data Centers

As suggested earlier, the rapid proliferation of AI has caused power consumption in server racks to skyrocket, pushing traditional 48 VDC power delivery to its physical limits. To overcome these challenges, high-voltage DC systems, such as 800 VDC and ±400 VDC, have emerged as the definitive solution.

However, simply increasing the voltage is not enough; comprehensive optimization and higher efficiency across the entire power circuit are essential. Thanks to advancements in next-generation power semiconductors like SiC and GaN, alongside innovative control technologies, architectures that achieve both high efficiency and high power density are becoming a reality. HVDC and advanced circuit technologies are now the two essential pillars supporting the next generation of data centers.

Visit ROHM’s Servers and Data Centers page to learn how ROHM is shaping the future of efficient, scalable data center infrastructure.

References

[1] Infineon Technologies. Infineon and ROHM collaborate on silicon carbide power electronics packages to enhance flexibility for customers [press release]; 2025 Sep 25. Available from: https://www.infineon.com/press-release/2025/INFXX202509-149

[2] ROHM Co., Ltd. ROHM delivers high-performance power solutions aligned with NVIDIA 800V HVDC architecture [press release]. ROHM Co., Ltd.; 2025 Jun 12. Available from: https://www.rohm.com/news-detail?news-title=2025-06-13_nvidia