PLA Bed Temperature & Print Temperature Settings

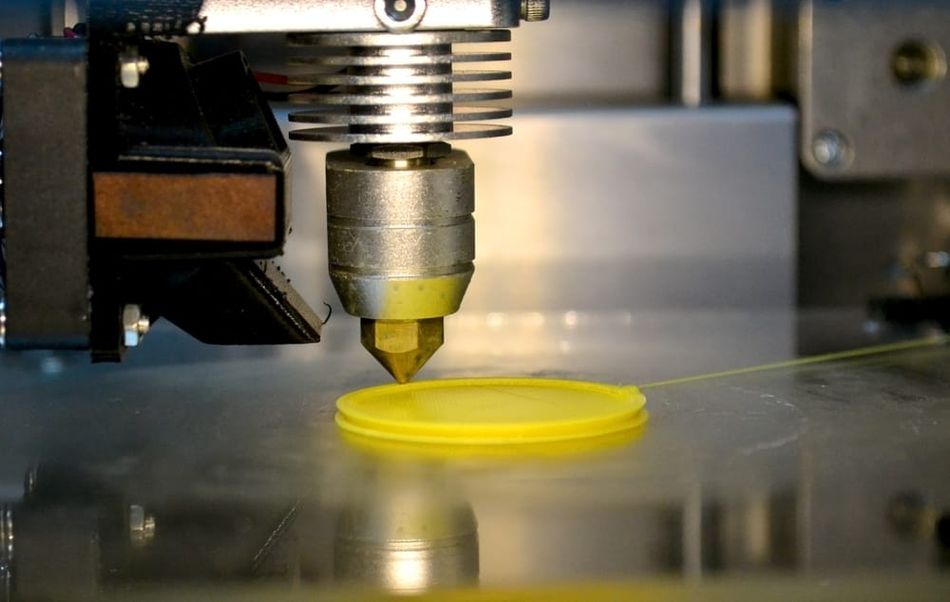

With its low melting point and resistance to warping, PLA is one of the easiest materials to print. However, users should still optimize the PLA bed temperature and nozzle temperature to obtain the best results.

PLA bed temperature and nozzle temperature can be kept low

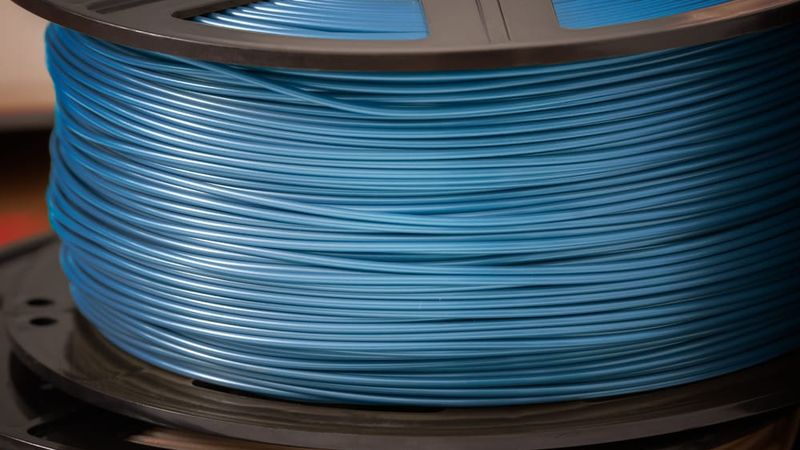

Polylactic acid (PLA) filament is the most popular material for consumer FDM 3D printing, and there are a few reasons why this is so. For one, PLA is highly affordable, meaning users can buy in bulk and iterate designs over and over without worrying about wasted material. Another reason for the material's popularity is the low PLA bed temperature and print temperature: with a glass transition temperature of around 60 °C, PLA can be printed using moderate heat settings without high-end, high-temperature equipment.

That being said, finding the ideal PLA bed temperature and print temperature isn’t always straightforward. Although the material generally requires low temperatures, the ideal range can vary depending on the brand of filament and the type of 3D printing hardware. And, as with other filaments, printing below or above the optimal temperature range can lead to issues like under-extrusion or stringing. Furthermore, the particularly low melting point of PLA makes it susceptible to a range of temperature-related 3D printing issues even after it has been printed.

This article serves as an introductory guide to PLA bed temperature and print temperature settings. It suggests suitable temperature ranges, identifies symptoms of printing at too high or too low a temperature, and offers tips on discovering the optimal temperature range for your specific 3D printing setup.

Thermal Properties of PLA

The thermal properties of PLA play a significant role in its performance during the 3D printing process. One of the key thermal properties of PLA is its glass transition temperature, which is the temperature at which the material changes from a hard, glassy state to a soft, rubbery state. For PLA, this is typically around 60 °C.

Another important thermal property of PLA is its melting temperature. This is the temperature at which the material changes from a solid state to a liquid state. For PLA, the melting temperature is typically in the range of 130–180 °C. This relatively low melting temperature is one of the reasons why PLA is favored in 3D printing. It allows for easier extrusion through the printer nozzle and better control over the printing process.

However, these thermal properties also mean that PLA is not suitable for high-temperature applications. Objects printed with PLA can deform if exposed to temperatures above its glass transition temperature. Therefore, understanding these thermal properties is crucial when 3D printing with PLA, as they directly influence the optimal print and bed temperature settings.

PLA Bed Temperature

One of the key advantages of PLA — especially for beginners — is its ability to be printed without a heated print bed. This makes it suitable even for low-cost printers without heated bed capabilities.

For FDM 3D printing materials generally, a heated bed provides some important benefits. Firstly, it helps with bed adhesion. When the print bed is hotter than the ambient temperature, it allows the first layer of extruded filament to stay soft for longer, giving more time for first-layer adhesion to take place. Additionally, when the heated bed is eventually switched off, the rapid temperature reduction can help facilitate part removal; in some cases, the finished parts will simply “pop off” the build surface. A heated bed can also improve print quality by reducing warping. Parts cool down slower, reducing the severity of contraction and curling.

Due to its low printing temperature, PLA is actually fairly resistant to first-layer adhesion issues and warping, especially compared to common alternatives like ABS. However, using the heated bed of a 3D printer can sometimes lead to better results when printing PLA, especially when the room temperature is on the cooler side or when printing a particularly large part.

If using a heated build plate when printing PLA, a temperature of around 50 °C works best. Cura, the popular slicer application, uses a value of 60 °C on its PLA print profile. Here are some recommended PLA print bed temperature settings from a selection of material manufacturers:

MatterHackers Build Series PLA: 40±15 °C

Fillamentum Extrafill PLA: 55 °C

Ultimaker PLA: 60 °C

Build surface

Note that the heated bed temperature is not the only factor that affects first-layer adhesion. The build surface is equally important: when printing PLA, glass coated with an adhesive like hairspray or glue stick provides good adhesion as well as good print surface quality on the bottom layer. Calibrating the bed level can also improve the adhesion of PLA printed parts on the printer bed.

PLA Print Temperature

When attempting to get the best results from PLA filament, the nozzle or hot end temperature is more important than the bed temp. The print temperature affects the print in several ways: higher temperatures improve material flow, enabling faster printing and good interlayer bonding.[1] However, too high a temperature can result in overly melted extruded layers which then sag and cause part deformation, in addition to other problems like material accidentally oozing from the nozzle. Using the lowest temperature you can get away with can therefore lead to the best visual results.

Compared to other thermoplastic printing filaments, PLA prints best at a moderate temperature, typically around 210 °C. To put that into perspective, that’s around 50 °C cooler than you would use for ABS and 30 °C cooler than PETG. The reason for PLA’s low print temperature is the very low (around 60 °C) glass transition temperature of the material.[2] However, the optimal printing temperature depends on a few different variables. These include the specific filament variety, the printing speed (faster prints require a higher temp), and the nozzle size (larger diameters need a higher temp).

Rather than attempting to compute all these different variables at once, the best way to determine PLA print temperature is to run some test prints, as discussed in the final section of this article.

Most FDM printer users set their PLA print temperature to around 210 °C. Here are some recommended PLA print temperature settings from a selection of material manufacturers:

MatterHackers Build Series PLA: 205±15 °C

Fillamentum Extrafill PLA: 220±10 °C

Ultimaker PLA: 200–210 °C

Recommended reading: PLA vs ABS: Which filament should one use?

PLA Enclosure Temperature

Because PLA requires such low bed and printing temperatures, and since its fumes are non-toxic, it generally does not require a printing enclosure to regulate the ambient temperature or prevent fumes escaping.

In fact, enclosures often have a detrimental effect on PLA prints, with the raised air temperature potentially causing issues such as nozzle jams. Other problems caused by enclosures can include issues with delicate areas like overhangs and bridges, which can become overly soft and cause part failure. That being said, some researchers have found success using environmentally controlled enclosures for the printing of PLA.[3]

If using an enclosure cannot be avoided, try printing PLA with the door of the enclosure left ajar, or, if possible, use exhaust fans in the printer to prevent the enclosure temperature getting too hot.

Symptoms of Too-High Temperatures

Failed or low-quality PLA prints are often the result of overly high bed or print temperatures. Setting these values too high can occur when using the wrong printing profile in your slicer, for instance, or when using a narrower nozzle diameter that requires a lower print temperature than the default settings.

Symptoms of excessive PLA bed temperature:

Elephant’s foot: A common PLA printing issue is when the first few layers of the print are splayed outwards due to being overly melted by the heated print bed then subjected to stress from subsequent layers. Elephant’s foot can be resolved by reducing the PLA bed temperature or disabling the heating function altogether.

Over-adhesion: A heated bed can improve the first-layer adhesion of PLA parts. But setting the PLA bed temperature too high can actually lead to the part sticking too well and requiring extensive scraping to remove it from the build surface. Slightly lower temperatures can maintain adhesion while reducing the need for scraping and prising.

Symptoms of excessive PLA print temperature:

Heat creep: If the nozzle temperature is too high, it can inadvertently melt the filament outside of the designated melt zone, especially when using an all-metal hotend. Heat creep often kicks in midway through a print, after the temperature has gradually risen up the hotend, and results in patchy or incomplete sections.

Sagging: When printed at too high a temperature, PLA parts can droop and sag, particularly during bridging (the printing of unsupported horizontal features). This can often be resolved by reducing the print temperature or by increasing the cooling fan power. Note, however, that excessive cooling can potentially lead to other issues like poor interlayer adhesion.

Oozing and stringing: High nozzle temperatures can lead to inadvertent leakage of the material from the nozzle during travel movements. This issue can be mitigated by reducing the print temperature or adjusting retraction settings.

Recommended reading: 3D printer stringing: How to fix it

Symptoms of too-low temperatures

The low temperature requirements of PLA mean that issues caused by too-low temp settings are less common. However, these issues can still arise in certain circumstances: when using nonstandard PLA filament, when the ambient temperature is especially cool, or when using a wide-diameter nozzle, for example.

Symptoms of insufficient PLA bed temperature:

Poor first-layer adhesion: In rare instances, PLA can fail to adhere to the print bed, leading to a dislodging of the part and ultimate print failure. This issue might be fixed by increasing the bed temp, but other solutions can include lowering the cooling fan power, cleaning the build surface (or introducing an adhesive coating), and bed leveling.

Symptoms of insufficient PLA print temperature:

Under-extrusion: When printing PLA, an insufficient nozzle temperature can lead to under-extrusion, which can manifest itself as holes in the print or a rough surface texture.

Clogs and jams: Insufficient temperatures can lead to insufficient melting of the PLA filament, potentially resulting in clogging of the nozzle and jamming that interrupts the print. These issues can be mitigated by increasing the print temperature or using a wider nozzle.

Recommended reading: How to fix under extrusion: Maintenance and print settings

How to find the best PLA printing temperature

Manufacturers of PLA filament typically provide recommended bed temperature and nozzle temperature settings that are optimized for their unique product. In some cases, however, these recommended settings do not lead to satisfactory results.

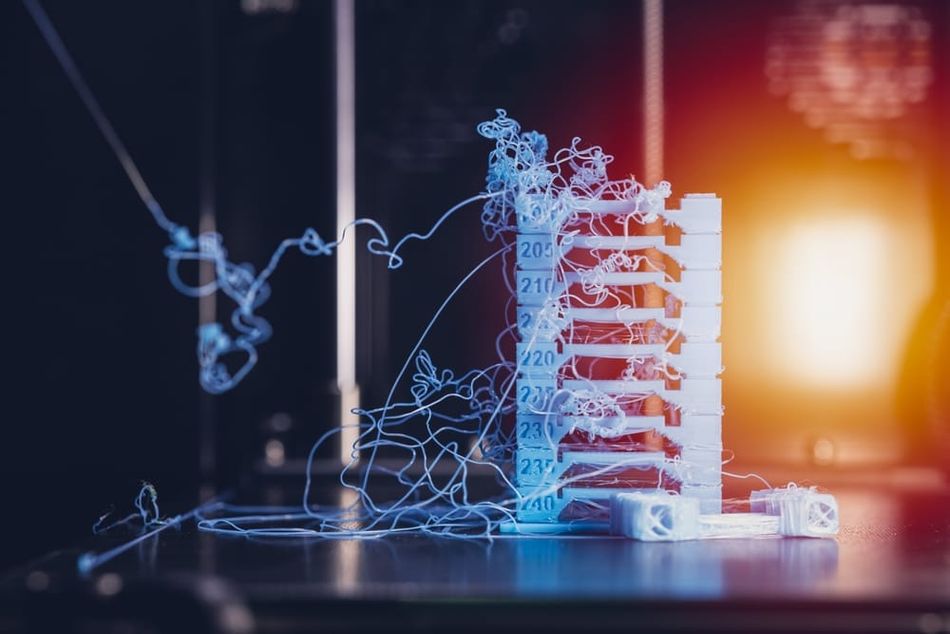

One way to find the best PLA printing temperature for your particular 3D printing setup — printer, nozzle, material, etc. — is to run some test prints and evaluate the results. But instead of printing a selection of ordinary parts, it can be helpful to print a particular 3D model known as a temperature tower.

A temperature tower such as this one consists of several horizontal blocks, each of which is printed at an incrementally higher or lower temperature than the last. The numbers are printed onto the side of the tower (200, 205, 210, and so forth) so the user can quickly identify which block has been printed at which temperature. Each block of the temp tower typically contains features like gaps, overhangs, and fine features, providing a clear picture of the printer’s performance with each different temperature setting.

Of course, printing a temperature tower is a little trickier than an ordinary print, because the slicer must instruct the printer to adjust the temperature at each relevant increment. (Cura users can install and utilize the ChangeAtZ plugin to switch the nozzle temperature at the required intervals along the Z-axis.)

When the temperature tower has finished printing, users can simply visually inspect the print to see which blocks have printed well and which have not. The block with the least stringing or artifacts and the best quality on fine features indicates the optimal print temperature for the material on that specific printing setup.

Conclusion

In general, the best PLA bed temperature is around 50 °C, while the best PLA print temperature is around 210 °C. A printing enclosure is not required and can even have a detrimental effect upon print quality, so exhaust fans should be used if an enclosure must be used. As we have seen, however, different factors — filament brand, nozzle diameter, print speed, etc. — can affect the optimal bed and nozzle temperature range, which makes testing imperative when printing PLA for the first time.

Frequently Asked Questions (FAQs)

Why is my PLA print not sticking to the bed?

If your PLA print is not sticking to the bed, it could be due to a bed temperature that is set too low. Try increasing the bed temperature incrementally and observe the effect on the print. Additionally, ensure that the bed is level and clean, as these factors can also affect bed adhesion.

Why is my PLA print stringy or messy?

Stringiness or messiness in a PLA print is often a sign of over-extrusion, which can be caused by a print temperature that is set too high. Try reducing the print temperature incrementally and observe the effect on the print. Additionally, check the retraction settings on your printer, as incorrect retraction settings can also lead to stringing.

How can I find the optimal print temperature for my PLA filament?

One effective way to find the optimal print temperature for your PLA filament is to use a temperature tower. This is a 3D model that tests different temperature settings in a single print, allowing you to identify the temperature that produces the best results for your specific filament.

Can I use the same temperature settings for all brands and colors of PLA?

While there are general temperature ranges that work well for most PLAs, the optimal temperature settings can vary slightly depending on the specific PLA product. Different brands can have slightly different formulations, and different colors can absorb heat differently. Therefore, it's recommended to experiment with different temperature settings when using a new brand or color of PLA.

References

[1] Vanaei HR, Raissi K, Deligant M, Shirinbayan M, Fitoussi J, Khelladi S, Tcharkhtchi A. Toward the understanding of temperature effect on bonding strength, dimensions and geometry of 3D-printed parts. Journal of Materials Science. 2020 Oct;55(29):14677-89.

[2] Bergström JS, Hayman D. An overview of mechanical properties and material modeling of polylactide (PLA) for medical applications. Annals of biomedical engineering. 2016 Feb;44(2):330-40.

[3] Lugo CA. The Design and Development of an Environmentally Controlled Enclosure for 3D Printers. Widener University; 2022.