Industry Impact of Extended Date Codes

Blind adherence to the 'two-year' date code has had unexpected impacts on the industry.

Understand the Future of Component Traceability with Our Latest Whitepaper

The semiconductor industry drives advancements across critical sectors such as aerospace, medical devices, automotive, and industrial automation. But despite semiconductors' transformative impact, the industry's logistics pose significant challenges, particularly in maintaining the continuity and reliability of supply chains. Traditional methods, notably the "two-year date code," have increasingly failed to meet the modern demands for traceability and quality assurance.

We are pleased to have partnered with Rochester Electronics to launch the white paper: Beyond Date Codes: The Importance of Traceability in Semiconductor Reliability and Supply Chain Resilience.

Download the full whitepaper below.

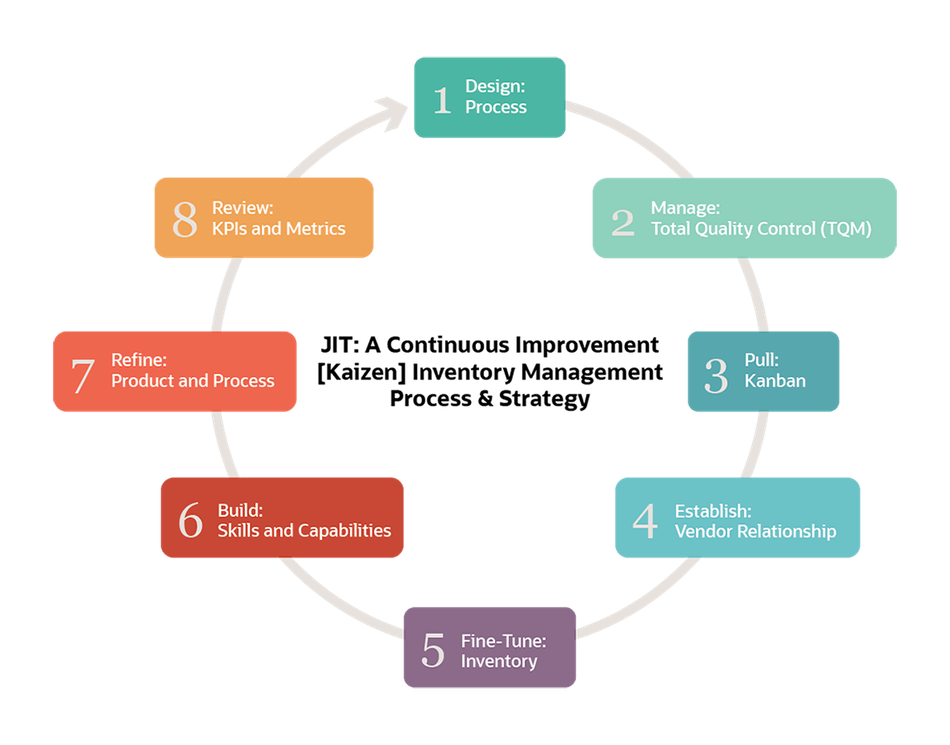

The semiconductor industry’s long adherence to the two-year date code as a standard for component usability has had an outsized influence on financial models, supply chain logistics, and procurement policies. Part and parcel with the just-in-time (JIT) inventory management philosophy, the date code constraint was initially intended to streamline operations, minimize excess inventory, and mitigate perceived risks associated with older components. However, recent global disruptions—most notably the COVID-19 pandemic—have exposed the vulnerabilities of such a rigid framework.

The Just-in-Time Model and the Two-Year Date Code

The two-year date code has remained an industry staple largely due to its alignment with JIT supply chain practices. JIT prioritizes lean inventory management by minimizing storage costs, reducing excess stock, and aligning procurement with real-time demand. This approach has proven effective for industries where high inventory turnover is a primary metric of efficiency but has inadvertently reinforced the perception that components older than two years are less viable.

The flow of a Just-In-Time inventory management strategy. Image credit: Oracle Net Suite

For example, the semiconductor distribution sector heavily relies on turns ratios, a metric that quantifies how often inventory cycles through a distributor’s stock within a given year. Large distributors often achieve turns ratios ranging from 6x to 12x annually, indicating that stock is replaced every one to two months [12]. As a result, components older than two years are often seen as financial liabilities rather than viable assets despite technical evidence supporting their long-term usability.

While effective for short-lifecycle products, this emphasis on rapid inventory turnover has had unintended consequences for industries requiring long-life semiconductors. Aerospace, medical devices, industrial automation, and automotive applications often depend on components that remain operational for 25 years or more. The reliance on arbitrary date code constraints in these sectors has, therefore, led to unnecessary component scrapping, procurement difficulties, and supply chain inefficiencies.

Lessons from the COVID-19 Pandemic

The semiconductor shortages that emerged during the COVID-19 pandemic provided a real-world stress test for the industry’s reliance on the two-year date code. As supply chains collapsed and lead times for new components stretched to over a year, manufacturers were forced to reconsider their restrictions on older inventory.

Historically, OEMs and contract manufacturers maintained rigid policies against procuring components exceeding a specific date code threshold. However, the pandemic necessitated an exceptional shift in procurement practices. Industries that had previously imposed strict date code limitations found that properly stored, older inventory authorized distributors with controlled storage environments performed identically to newer stock.

This period highlighted the flaws in the JIT model and demonstrated the resilience benefits of strategic inventory reserves. While JIT optimizes short-term efficiency, it leaves supply chains vulnerable to disruptions, shortages, and geopolitical instability. The pandemic forced manufacturers to embrace extended date codes and proved that long-term semiconductor storage is both technically viable and essential for operational continuity.

Despite these lessons, many in the industry have already begun reverting to pre-pandemic procurement models. A lasting, structural reevaluation of date code limitations is necessary to build more adaptive, resilient supply chains that can withstand future disruptions.

Challenges of Adopting Extended Date Codes

While the technical feasibility of extended date codes is well-documented, shifting industry norms require overcoming entrenched perceptions, regulatory constraints, and logistical challenges.

Industry Resistance and Legacy Perceptions

Skepticism surrounding older components remains pervasive despite empirical evidence demonstrating their reliability. Many stakeholders, particularly in contract manufacturing and procurement, have relied on historical concerns over solderability degradation and oxidation to justify date code restrictions. However, controlled storage environments, advances in moisture-resistant packaging, and JEDEC-compliant storage standards have effectively mitigated these risks.

Convincing the industry to move beyond legacy concerns requires a shift in education and awareness. Procurement teams must recognize that date code alone is not a reliable indicator of component viability. Instead, emphasis should be placed on storage conditions, traceability records, and quality assurance measures, all of which provide a far more accurate assessment of component integrity.

Regulatory and Contractual Constraints

In industries such as aerospace, defense, and medical devices, regulatory frameworks often impose strict date code limitations under the assumption that older components introduce increased failure risk. For example, many government contracts specify maximum date code thresholds, limiting procurement flexibility. Updating these frameworks to reflect modern storage and traceability capabilities will require collaboration between regulatory agencies, industry groups, and component manufacturers.

Reevaluating Testing Requirements

A common misconception is that extended date codes necessitate additional testing. In reality, properly stored components do not require further verification beyond standard industry quality checks. However, for components where storage conditions are unknown or where inventory exceeds the timeframe of existing reliability data, manufacturers may conduct additional assessments such as solderability testing, X-ray inspection, and electrical parameter verification. These measures are precautionary rather than required for all older components.

Opportunities for a More Resilient Supply Chain

Beyond addressing technical concerns, an industry-wide shift toward extended date codes presents significant operational and financial advantages.

A more flexible approach to date codes would increase inventory availability during supply chain disruptions and allow manufacturers to access a broader range of fully traceable, high-quality components. Authorized distributors specializing in long-term semiconductor storage are well-positioned to facilitate this transition and ensure that stored inventory remains compliant with JEDEC and AS6496 standards.

Extending the usability of older, properly stored components would also reduce electronic waste and lower procurement costs. Each year, millions of dollars worth of semiconductor inventory is discarded due to arbitrary date code constraints despite meeting all functional and reliability criteria. By adopting a data-driven, traceability-backed approach to extended date codes, the industry could recover significant value while improving supply chain sustainability.

Finally, modern traceability systems, including IoT and RFID technologies, provide an additional safeguard that allows manufacturers to verify that components have been stored under compliant conditions. These systems offer a level of data transparency that further supports the adoption of extended date codes.

A Path Forward for Semiconductor Inventory Management

The two-year date code originated from a combination of legacy manufacturing constraints, JIT supply chain philosophy, and financial turnover metrics. While once a pragmatic approach to inventory management, this rigid constraint no longer reflects the realities of modern semiconductor manufacturing, controlled storage, and traceability capabilities.

As a leader in long-term semiconductor storage and traceability, Rochester Electronics provides an alternative to wasteful inventory turnover practices by ensuring that every component remains fully traceable, compliant, and reliable, regardless of the date code. The future of semiconductor inventory management lies in evidence-based decision-making, where storage conditions, not arbitrary time constraints, determine component viability.

References

https://www.ti.com/lit/wp/slva304/slva304.pdf?ts=1737699355450

https://rocelec.widen.net/s/pxdp2p9tdd/futureproofingaerospacewhitepaper_eng

https://shop.ipc.org/ipcjedec-j-std-033/ipcjedec-j-std-033-standard-only/Revision-d/english

https://www.sciencedirect.com/science/article/abs/pii/S0925527320302358