Hybrid Analog-Digital Control for 50 W-1 kW Power Converters by ROHM's LogiCoA™

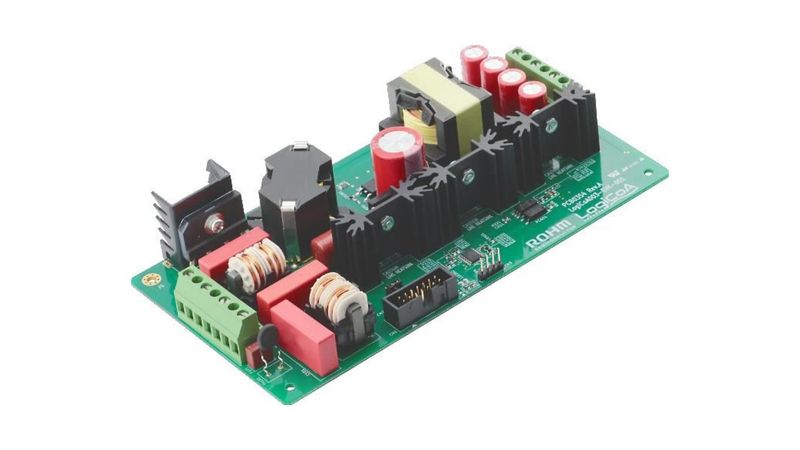

Conventional microcontrollers make digital control impractical in 50 W-1 kW power supplies due to cost and power demands. ROHMs LogiCoA™ overcomes this with a hybrid, event-driven design that adds calibration, logging, and software flexibility for efficient, scalable power electronics solutions.

Introduction

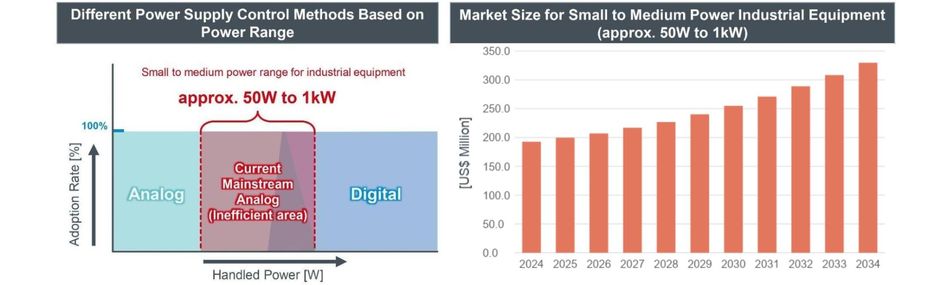

Power electronics is evolving rapidly, with increasing demand for smarter, more efficient, and scalable power supply solutions. While digital control promises these capabilities, its adoption has been slow in the small-to-medium power range (50 W to 1 kW) due to the cost and power demands of conventional microcontrollers. As a result, analog control continues to dominate this segment, offering low cost and low power consumption but limited functionality.

This article explores how ROHM’s Logic and Control Architecture (LogiCoA™) architecture addresses this long-standing challenge. By combining analog efficiency with digital flexibility, LogiCoA™ makes advanced digital control practical in the volume zone of industrial equipment. The sections that follow explain the limitations of existing solutions, introduce the hybrid approach behind LogiCoA™, and highlight the new possibilities it creates for cost, performance, and design flexibility.

Challenges of Applying Digital Control to 50 W-1 kW Power Converters

Microcontrollers for digitally controlled power supplies are not a novel concept - many semiconductor manufacturers have long offered solutions in this space, and they’re already integrated into a wide range of applications. What sets LogiCoA™ apart is its innovative approach to overcoming persistent limitations that conventional microcontrollers had yet to resolve.

The issue lies in the fact that existing digital control microcontrollers are expensive and consume significant power. Consequently, they are primarily applicable to high-power areas in industrial equipment power systems, where the output exceeds 1kW. However, they are challenging to utilize in the small-to-medium power range of approximately 50 to 1kW, which represents the volume zone.

Even in low to medium power range power systems, there is a strong demand to leverage the advanced functionalities unique to digital control power supplies. However, due to cost and power consumption issues, the adoption of digital control power supplies remains hesitant.

Table 1: Features of analog-controlled power supplies vs. digitally controlled power supplies.

Parameter | Analog Control | Digital Control |

Cost | Excellent - No need for CPU | Neutral - Requires high-speed CPU/DSP (higher cost) |

Power Consumption | Excellent - Low (Icc = 3mA to 5mA) | Negative - High (Icc = 100mA to 150mA) |

Functions | Negative - Low functionality, cannot support complex functions | Excellent - Can add advanced features like calibration and log acquisition |

Revamping the Configuration of the PWM Control Loop

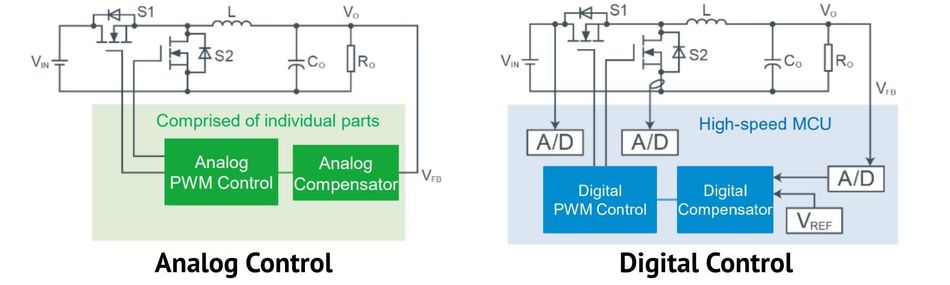

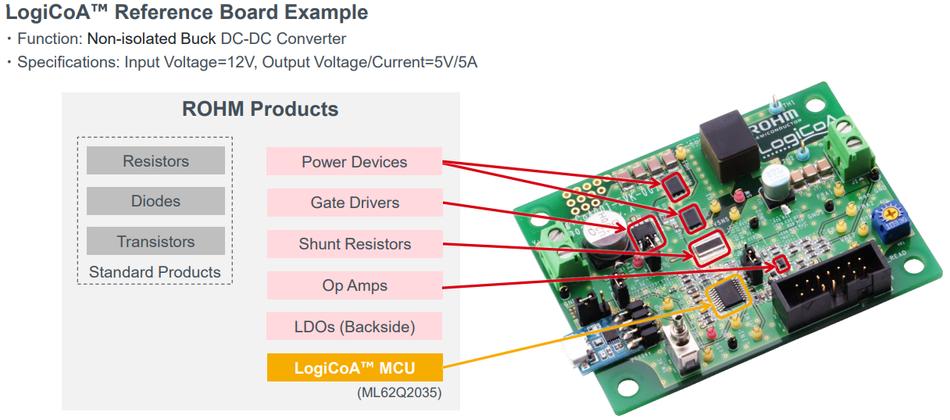

The cost and power consumption issues that existing microcontrollers for digitally controlled power supplies faced were resolved by LogiCoA™ through the hybrid of analog and digital technologies. Generally, digitally controlled power supplies utilize A-D converters and CPU/DSPs to construct PWM control loops. To minimize the delay time within these control loops, high-speed A-D converters and high-performance CPU/DSPs are essential.

However, this has been the main cause of high costs and significant power consumption. To address this, LogiCoA™ revamped the configuration of the PWM control loop. Instead of using high-speed A-D converters, it utilized external analog compensators, such as error amplifiers.

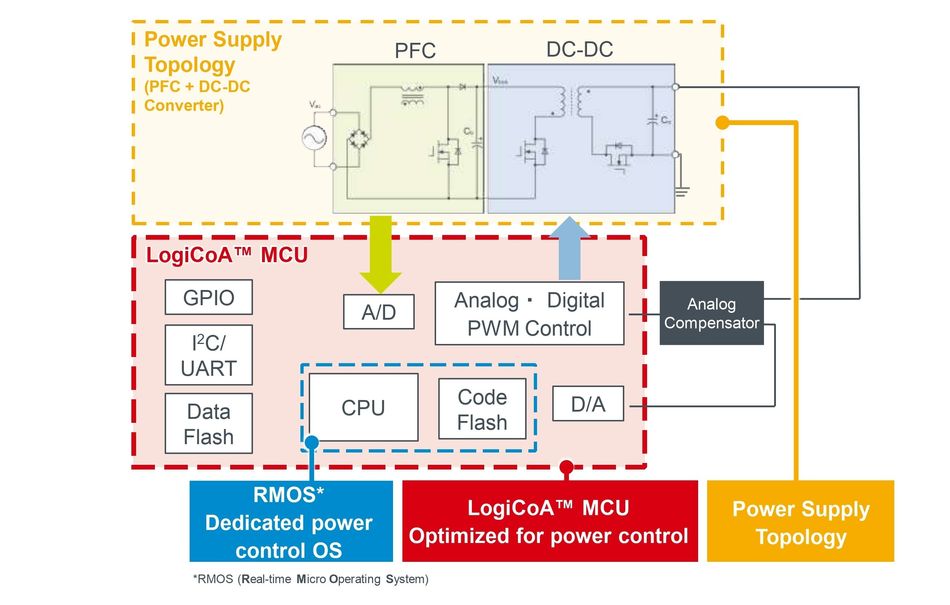

The processing of PWM control is executed by an analog-digital PWM control circuit consisting of built-in comparators and timers. Analog signals input from the analog compensators are used as triggers for high-resolution timers, allowing the duty cycle of PWM signals to be controlled on each clock signal cycle without involving the CPU. Since control is initiated upon receiving signal input from the analog compensators, this method is referred to as "event-driven."

The impact of revising the PWM control loop configuration has been tremendous. Compared to using existing microcontrollers for digitally controlled power supplies, costs can be reduced to about one-third to one-fourth, and power consumption can drop to about one-thirtieth. This breakthrough has paved the way for applying digital control to power systems in the small-to-medium power range for industrial equipment.

Equipped with logging and calibration functions

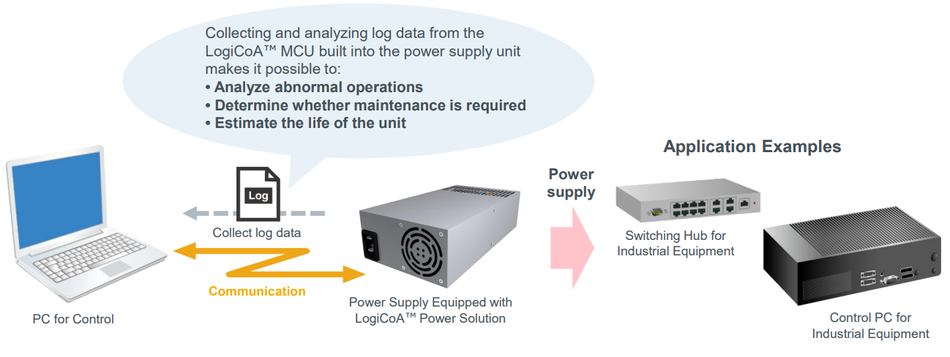

While LogiCoA™ integrates a CPU on the IC, it takes a unique approach by excluding the CPU from the real-time PWM control loop calculations. Instead, the CPU operates in the background, handling tasks such as power supply startup and shutdown, input/output monitoring, current sensing, and managing external communications - based on user-defined software routines. This architecture improves efficiency and enables several advanced features that are characteristic of digitally controlled power supplies. The following sections highlight these distinctive capabilities:

The first advantage is the ability to adapt to various power topologies through software modifications. Typically, analog-controlled power ICs only support a single topology, requiring power supply manufacturers to prepare numerous product variants, which increases the burden of inventory management. However, with LogiCoA™, a single device can accommodate multiple topologies, significantly reducing the challenges of inventory management.

Another key feature is the ability to finely adjust circuit elements using the calibration function. Circuit elements such as ICs, power devices, and transformers used in power systems often have variations in their characteristic values. As a result, circuit design must include sufficient margins relative to the ratings of each element. This leads to larger dimensions for circuit elements, higher voltage resistance requirements, and subsequently, larger and costlier power systems. By utilizing LogiCoA™’s calibration function, these variations can be fine-tuned - allowing for smaller margins and enabling the miniaturization and cost reduction of power systems.

Real-time power control with ROHM’s RMOS

The software side of LogiCoA™ is powered by ROHM’s proprietary real-time operating system, Real-time Micro Operating System (RMOS), which is provided free of charge. RMOS supports two “state transition control modules,” enabling simultaneous control of PFC circuits and DC-DC converters - or two DC-DC converters. To simplify development, sample code is available for various topologies, and operating parameters can be easily configured using an Excel-based tool.

Local user support throughout Europe is handled by ROHM's Application and Technical Solution Center in Willich, near Düsseldorf, Germany. Additionally, a dedicated support division for LogiCoA™ in Japan is equipped to provide assistance. This ensures that users in Europe can adopt the technology with confidence.

Conclusion

LogiCoA™ represents a massive shift in digitally controlled power supply design. By offloading real-time PWM control to an analog-digital circuit and reserving CPU resources for background tasks, it achieves dramatic reductions in cost and power consumption without sacrificing functionality. Features such as topology reconfigurability, calibration, and log acquisition further enhance system performance while reducing design complexity and size.

Together with ROHM’s RMOS operating system and dedicated global support, LogiCoA™ provides a practical path to digital control in the critical 50 W to 1 kW power range. This hybrid approach bridges the gap between analog and digital control, and sets a new standard for scalable, efficient, and intelligent power management.

Explore ROHM’s LogiCoA™ solutions and start designing today.

*LogiCoA™ is a trademark or registered trademark of ROHM Co., Ltd.

This article was contributed to and edited by Ravi Rao.