High-Bandwidth Automotive Connectivity with GEMnet Connectors by TE Connectivity

Building the Data Backbone of Vehicles with GEMnet Solutions by TE Connectivity — combining Multi-Gigabit Bandwidth, Robust EMI Shielding, and Automotive-Grade Durability

Modern vehicles are evolving into mobile computing platforms where vast networks of sensors, displays, and control systems interact in real-time. This has converted automobiles into interconnected ecosystems that constantly capture, process, and transmit large volumes of data. In this regard, modern cars depend on reliable, high-throughput connectivity to function as intended.

The global automotive sensors market is projected to grow from approximately $29 billion in 2025 to $35 billion by 2027, at a compound annual growth rate of about 10.1%. 1 As vehicles incorporate more sensors and real-time systems, the volume of data they generate and process is outpacing the capabilities of traditional network infrastructures. Meeting this challenge requires a new generation of connectivity solutions capable of handling high data rates with robustness and efficiency. This article discusses how TE Connectivity’s GEMnet differential connector systems fulfill the data transmission requirements in modern vehicles by providing robust, high-speed communication links that support advanced sensing, visualization, and infotainment systems.

The Bandwidth Explosion in Modern Vehicles

Modern vehicles generate and process massive volumes of data as they integrate multiple high-resolution cameras, radar, LiDAR, and advanced display systems. These components continuously stream high-definition data to support safety features, driver assistance, and immersive infotainment.

Cameras are among the most data-intensive sources. The global vehicle camera market, valued at around $8.8 billion in 2023, is expected to reach $22.5 billion by 2032. Advanced driver-assistance and vision-based safety features are among the few causes for such growth. Moreover, the average camera counts per vehicle have risen from 2.6 in 2021 to a projected 4.6 by 2027, with experimental prototypes already employing 11-12 cameras. Fully autonomous models may rely on 20 or more cameras, along with radar and LiDAR arrays, to ensure comprehensive environmental awareness. 3, 4, 5

Moreover, HD cameras are also extending into new areas, such as 4K and 8K dashcams. For instance, the 4K dashcam market is forecasted to grow to $2.54 billion by 2029, at a CAGR of roughly 11%. 6 Similarly, LiDAR and radar sensors are becoming more precise and frequent. Large-format infotainment and passenger displays also require continuous video transmission.

These developments have altered vehicle data requirements to the extent that previous generations of cars could rely on megabit-scale communications. Still, today’s connected, partially autonomous platforms require multi-gigabit throughput and highly deterministic transmission performance. This dependency on high-bandwidth data flows is making traditional communication protocols obsolete.

Why Legacy Architectures Fall Short?

Conventional automotive communication architectures were not designed for the data-intensive use cases. Technologies such as 1 Gbps Ethernet, CAN, or traditional Low Voltage Differential Signaling (LVDS) were adequate when vehicles transmitted only control messages or limited multimedia content. However, these systems encounter performance ceilings when required to handle continuous 4K or 8K video streams from multiple sensors. When these networks are pushed beyond their capacity, latency, jitter, and buffering increase, leading to inconsistent data transmission. The disruptions can compromise real-time perception systems, where slight delays in video or LiDAR data can affect functions such as lane-keeping assistance or collision avoidance.

The limitations extend to physical interfaces as well. Interface-specific limitations compound the issue. For instance, although HDMI connections are capable of high-resolution transmission, these are bulky, fragile, and unsuited to withstand the vibration, temperature fluctuations, and moisture typical of automotive environments. Similarly, LVDS lacks scalability for higher-resolution video. Its bandwidth ceiling and short transmission distance restrict its use in multi-camera or high-resolution applications, and increasing cable count also adds to harness complexity and weight. Therefore, these legacy interfaces cannot provide the throughput, robustness, or scalability required for advanced automotive systems, which demand communication links that combine high bandwidth, low latency, and environmental durability.

The GMSL Technology

Gigabit Multimedia Serial Link (GMSL) is a high-speed SerDes-based interface developed to meet the bandwidth and reliability needs of modern vehicle electronics. It enables the simultaneous transmission of video, control data, and power through a single lightweight coaxial or shielded twisted-pair cable. This means that multiple signal paths and bulky connectors are not needed.

GMSL helps manufacturers lower material costs and improve overall system efficiency by reducing cable count and weight. Moreover, the streamlined harness design also improves assembly flexibility and allows engineers to route high-speed links efficiently across constrained vehicle architectures.

Another significant advantage of GMSL technology is its resilience to electromagnetic interference (EMI). Its differential signaling design minimizes crosstalk and ensures stable signal integrity in the electrically noisy environments of modern vehicles. This results in reliable, low-latency data transmission essential for safety-critical functions such as camera-based driver assistance, real-time perception, and infotainment systems. GMSL is becoming a go-to choice for OEMs and Tier-1 suppliers developing high-bandwidth automotive networks due to its robustness, scalability, and compact architecture.

However, even with GMSL’s efficiency and scalability, automotive engineers still face several integration challenges. These are not limitations of the GMSL protocol itself but rather the practical engineering hurdles that OEMs may face when implementing it in real-world vehicle environments.

Engineering Challenges with GMSL Networks

Designing a robust network around GMSL has multiple hardware-level challenges. For instance, a major challenge can be harness complexity as engineers need to balance flexibility with durability and keep overall cable weight to a minimum. In large vehicle platforms, routing multiple high-frequency cables through tight spaces without introducing signal crosstalk or mechanical strain can become difficult.

EMI management and shielding are also critical. The same high-frequency signaling that enables multi-gigabit throughput also makes the system more susceptible to interference from electric motors, battery systems, and other vehicle subsystems. Maintaining clean signal integrity usually requires specialized shielding materials and grounding strategies.

Similarly, engineers must select between coaxial and shielded twisted pair (STP) cabling depending on space constraints, EMI tolerance, and cost considerations. In each case, cable compatibility or ensuring impedance matching between cables and connectors is essential to preserve signal integrity at high frequencies.

Connectors in GMSL networks should maintain consistent electrical performance despite constant vibration, temperature cycling, and exposure to humidity or contaminants. If not properly engineered, connectors can become the weakest link in the network, leading to signal loss, intermittent failures, or long-term reliability issues.

In most implementations, the connector ultimately defines the reliability and bandwidth consistency of the entire GMSL link, making high-performance connector systems vital for ensuring long-term stability and compliance with automotive standards. In many cases, the connector becomes the critical bottleneck if not engineered correctly.

TE Connectivity GEMnet: Built for Automotive Data Demands

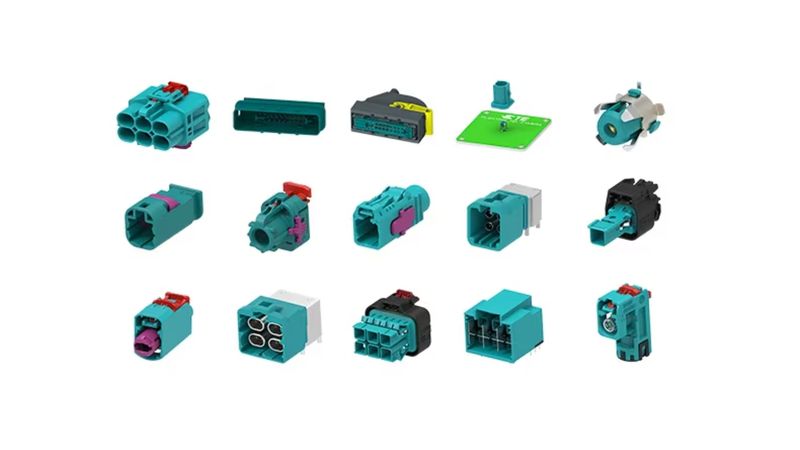

Addressing the physical integration challenges of GMSL networks requires connector systems that can deliver both electrical precision and mechanical durability. TE Connectivity’s GEMnet differential connector systems are engineered specifically for these requirements. They provide consistent performance in high-speed SerDes applications such as GMSL, A-PHY, and other multi-gigabit automotive data links.

The GEMnet architecture is optimized for differential-pair transmission up to 15 GHz, enabling data throughput of up to 56 Gbps. This bandwidth capacity supports the requirements of modern automotive sensing and visualization systems, including high-resolution cameras, LiDAR modules, and infotainment displays. The connectors maintain controlled impedance across mating interfaces, which minimizes signal reflections and ensures reliable transmission in extended cable runs.

The GEMnet designs are mechanically robust as each connector is built to tolerate continuous vibration, temperature cycling, and exposure to contaminants common in automotive environments. Their compact and lightweight construction reduces the overall harness mass. The housings and terminal materials are selected for long-term stability under thermal and mechanical stress, preventing micro-fretting and maintaining low contact resistance over the vehicle’s lifetime.

Moreover, GEMnet connectors provide strong electromagnetic shielding to limit radiated and conducted noise. This feature helps preserve data integrity in the dense, interference-prone electrical ecosystem of modern vehicles. The system’s modular configuration also allows engineers to scale their designs to different data-rate requirements or system architectures without extensive redesign.

TE Connectivity’s GEMnet series provides engineers with a foundation for implementing next-generation automotive networks by combining signal fidelity, environmental resilience, and design flexibility. When we integrate these connectors into GMSL-based systems, they address many of the practical challenges that otherwise limit performance.

Application Areas: Where GEMnet Shines?

The combination of high bandwidth, compact form factor, and strong shielding performance allows GEMnet connectors to be integrated across a wide range of automotive systems. For instance, they are used in advanced driver-assistance systems (ADAS), where multiple high-resolution cameras and radar units generate continuous data streams that need to be transmitted without latency or frame loss. GEMnet connectors maintain signal integrity across these links, supporting precise, real-time environmental perception required for adaptive cruise control, lane-keeping assistance, and collision-avoidance functions.

In infotainment & passenger display systems, GEMnet supports high-quality video transmission for 4K and 8K displays distributed throughout the vehicle cabin. Its low insertion loss and controlled impedance ensure stability of high-definition content over long cable runs. Similarly, in digital dashboards and head-up displays (HUDs), GEMnet connectors provide the reliability needed to convey critical driver information instantaneously and without data distortion.

In AR/VR-based cockpit systems, real-time rendering and low-latency data delivery are important. GEMnet connectors support the transmission of large visual datasets while maintaining resistance to interference. Their consistency allows designers to implement immersive interfaces and driver-monitoring technologies without compromising reliability.

Future-Proofing Automotive Connectivity

The ability to manage vast visual and sensor information with precision and reliability is becoming central to modern automotive design. In this environment, GMSL provides a solution for high-speed, low-latency communication across complex and advanced in-vehicle networks.

The long-term reliability of these systems depends not only on the communication protocol but also on the physical components that support it. In this regard, connectors and cabling help maintain consistent bandwidth and shielding performance across the vehicle’s lifetime. TE Connectivity’s GEMnet connector systems address these requirements by providing the mechanical durability and electrical performance needed to sustain high-frequency data transmission in demanding automotive conditions.

Manufacturers can create vehicle architectures that support future generations of high-resolution sensors and data-driven systems by aligning proven GMSL technology with robust connector designs.

Engineers and OEMs interested in exploring these solutions can find TE Connectivity’s GEMnet connector systems available through Mouser Electronics. For detailed specifications and ordering information, visit Mouser’s TE Connectivity product page.

References

- Tajammul Pangarkar (2025) Automotive Sensors Statistics 2025 By New Sensing Tech. [Online] Market.US. Available at: https://scoop.market.us/automotive-sensors-statistics/ (Accessed on: October 20, 2025)

- TE Connectivity GEMnet Multi-Gig Differential Connectors [Online] Mouser Electronics. Available at: https://www.mouser.com/new/te-connectivity/te-gemnet-differential-connector-systems/ (Accessed on: October 20, 2025)

- Automotive Electrical & Electronics / Automotive Camera Market. [Online] Fortune Business Insights. Available at: https://www.fortunebusinessinsights.com/industry-reports/automotive-camera-market-101912

- Vehicle Cameras Market Analysis & Forecast: 2025-2032. [Online] Coherent Market Insights. Available at: https://www.coherentmarketinsights.com/market-insight/vehicle-cameras-market-4341 (Accessed on: October 20, 2025)

- Anne-Françoise Pelé (2023) Cameras, Radars, LiDARs: Sensing the Road Ahead. [Online] EETimes Europe. Available at: https://www.eetimes.eu/cameras-radars-lidars-sensing-the-road-ahead/ (Accessed on: October 20, 2025)

- 4K Dash Cam Global Market Report 2025. (2025) [Online] The Business Research Company. Available at: https://www.thebusinessresearchcompany.com/report/4k-dash-cam-global-market-report (Accessed on: October 20, 2025)