Former coal miners learn to deploy lights out production in 2.5 weeks

Manufacturing faces a significant skilled labor shortage, which is expected to reach 3.5 million unfilled advanced manufacturing job openings by 2025.

The Business

Based in Paintsville, KY, eKAMI is a Haas Technical Education Center (HTEC) that is teaching former coal miners, and others seeking career advancement, CNC machining and other advanced manufacturing skills.

Task

Training future manufacturing professionals in advanced manufacturing.

The Challenge

Manufacturing faces a significant skilled labor shortage, which is expected to reach 3.5 million unfilled advanced manufacturing job openings by 2025. The industry needs more workers armed with the advanced manufacturing skills. Kathy Walker founded eKAMI, a Haas Technical Education Center, to address this need and also create opportunity for former coal miners who had been left behind by evolving energy policy.

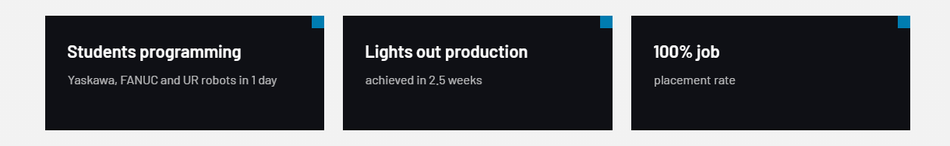

Over their first few years, eKAMI has trained over a hundred workers on CNC machine programming and operation, as well as other advanced manufacturing skills. Despite a 100% job placement rate, Kathy Walker realized that eKAMI must extend the skills of their graduates to include the ability to design, program, deploy, and manage robotic automation. These skills would multiply the impact that each graduate would have at their future employers, and ensure a bright future for eKAMI graduates.

However, the robotic landscape is extremely fragmented, with 70+ robot OEMs, each with its own difficult-to-learn programming language. Learning to program basic skills on any robot can take weeks, and require base programming knowledge like C+ or Pascal. This wasn’t a workable solution for eKAMI, as it would require greatly increasing the length of their 16-week training course in order to give their students basic robot programming skills - with just ONE robot brand! eKAMI needed a solution that would allow them to rapidly train their students to program multiple brands of robots, and also learn the related components of automation: automated workcell design, parts presentation, safety, programming and troubleshooting robotic automation, etc.

The Solution

When the eKAMI team discovered READY Robotics they knew they might have found the solution. READY’s Forge/OS enables operators to program multiple brands of robots from a single platform. With intuitive, flow-chart-based programming, Forge/OS drastically reduces the learning curve, enabling anyone to learn basic programming skills in under a day versus the weeks it takes with each robot’s native programming language. More than that, Forge/OS programming skills transfer to multiple top robotic brands, enabling students to become proficient programming Yaskawa, FANUC and other top brands in just a few days. It was clear to eKAMI leadership that building their automation education around Forge/OS would allow students to quickly expand their skillset to include robot programming. Equally importantly, it would also free up enough time for the students to learn the other skills necessary to successful design and deploy automation. READY was already hard at work on educational materials for their customers, and were happy to build and teach a 3-week automation course for eKAMI.

Whether you have some knowledge or zero knowledge with robotics, anyone can be easily taught how to run robots (with Forge/OS).

"Kaylee Maynard" - eKAMI Graduate

Within a couple of hours of robot time I was doing it (programming robots)!

"Mike Cepeda" - eKAMI Graduate

The Result

In August the eKAMI Haas Technical Education Center graduated their first class of students, skilled in both CNC machine programming and operation, as well as automation design, programming and deployment. With a 3-week automation add-on to their 16-week CNC course, this class of eKAMI graduates are able to program machine tools as well as deploy lights out production. Best of all, 3 weeks of automation didn’t just teach them the most basic of robot programming skills that they might have learned through a robot OEM. Instead, they learned how to evaluate potential automation projects, how to design an automated workcell, how to solve parts presentation, how to design and fabricate end-of-arm tooling, how to seamlessly integrate robots with machine tools, how to program robots and deploy automation, how to optimize automated workcells to maximize output, and how to achieve lights out production. With the help of Forge/OS and READY’s automation training curriculum, this class of eKAMI graduates is the first of many that will have the skills needed to help usher in the future of US manufacturing. One where automation is common across manufacturers of all sizes, and one where US manufacturing is once again a global manufacturing leader.

If I can do it, anyone can program robots with Forge/OS!

"Tim Miller" - eKAMI Graduate

Highlights

Former coal miners upskilled into automation experts in 3 weeks