Fighting Obsolescence by Aligning with Automotive

Why Is Alignment with the Automotive Industry the Best Defence of Industrial Electronics Against Obsolescence?

It's an unfortunate truth that the industrial semiconductor market lacks the volume necessary to influence global manufacturing priorities. Without much leverage, industrial OEMs need to piggyback on a sector that shares their requirements but commands the necessary economic influence. Between the dominant semiconductor segments, the automotive industry offers the most viable parallel for the industrial sector.

Automotive vehicles and heavy industrial machinery share fundamental engineering characteristics. Both applications require safety assurance, operational lifespans measured in decades, and resilience against environmental conditions that would compromise standard consumer electronics. Because the automotive sector has established robust supply chain mechanisms to address these challenges, industrial manufacturers can fight obsolescence by aligning with automotive component standards and partnership models.

Leveraging the Stability of AEC Standards

Automotive semiconductors occupy a unique position in the global supply chain. They must meet strict, quality and reliability standards well-defined by the Automotive Electronics Council (AEC), including AEC-Q100 for integrated circuits and AEC-Q200 for passive components (1). The industry designed these standards to guarantee that devices operate safely under extended environmental stress, including many of the same conditions that industrial and heavy-equipment systems also endure daily.

When industrial engineers select components that adhere to these automotive qualifications, they effectively secure a product lifecycle engineered for longevity. While data center engineers revise designs every three to five years, automotive product lifecycles last between 15-20 years. Consequently, when an industrial controller incorporates an AEC-qualified microcontroller, the design directly benefits from the longer support timeline.

Beyond technical durability, aligning with automotive provides a safeguard against the economic drivers of obsolescence. Original Component Manufacturers (OCMs) frequently discontinue products when production volumes fall into unprofitable territory. Conversely, AEC-qualified components enjoy support from high-volume, multi-year production runs across diverse vehicle platforms. By integrating these devices, industrial designers access a supply chain supported by the substantial demand of the global automotive industry, which significantly reduces the probability of discontinuation due to unmet revenue targets.

Adopting Automotive Process Discipline

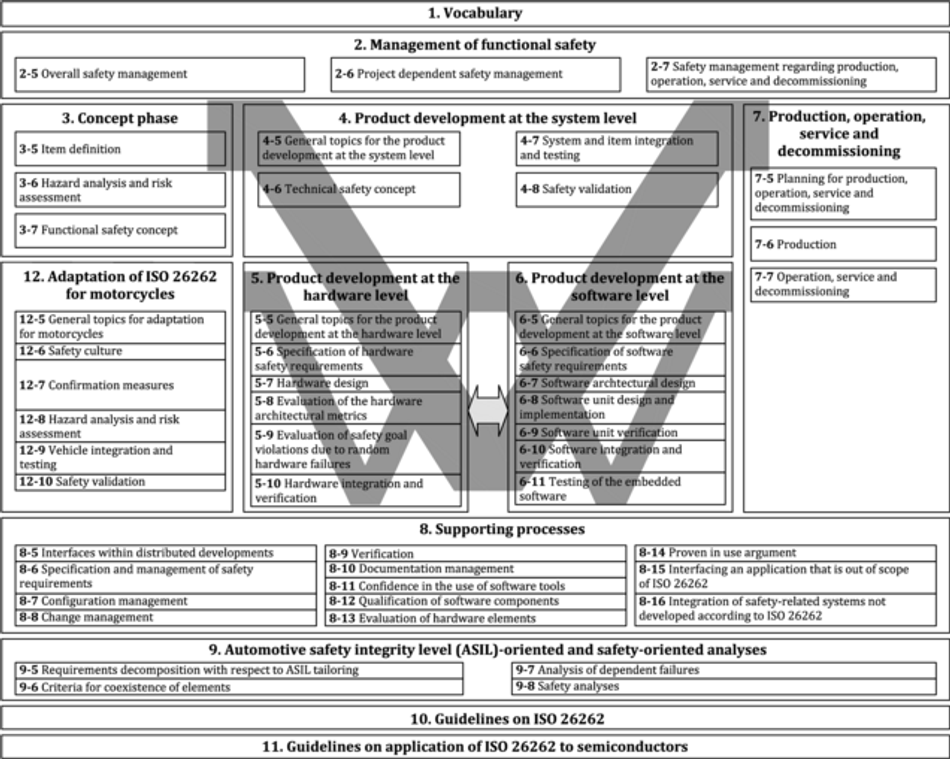

The value of the automotive sector goes well beyond the components themselves. Automotive engineering follows a strict methodology that prioritizes functional safety, as codified in standards such as ISO 26262 (2). Although industrial manufacturers typically operate under different regulatory frameworks, such as IEC 61508, the fundamental requirement for process discipline is mostly the same.

Image credit: ISO(2)

Therefore, aligning with automotive-grade suppliers gives industrial OEMs robust documentation and traceability. AEC-qualified components come with detailed process control data, which proves essential for future reliability validation. And, because automotive programs prioritize stability to minimize risk, they utilize well-characterized packaging and test platforms that aren’t threatened by abrupt retirement.

Rochester leverages these same advantages when extending product lifecycles with internal manufacturing that follows the same quality controls expected of automotive programs, including environmental stress screening, burn-in, and lot traceability. By applying automotive manufacturing discipline to industrial components, Rochester ensures that replicated or remanufactured parts meet the same reliability expectations as their originals.

Supplier Selection as a Risk Mitigation Strategy

Combating obsolescence requires a strategic approach to supplier selection, as OCMs vary significantly in their long-term commitments. While some establish reputations for supporting long-lifecycle industrial and automotive programs, others prioritize the blistering innovation cycles of GPUs, FPGAs, and high-performance computing. Manufacturers of industrial controls introduce considerable risk when they select a supplier focused on short-lifecycle markets.

For example, when a processor family reaches its end of life, the resolution rarely involves a simple component swap. Engineers must often rewrite firmware, revalidate hardware layouts, and retest for global certifications. These processes can take years of engineering effort and significant capital expenditure. Companies can avoid this scenario by selecting and proactively engaging with suppliers that show a proven track record of stability.

As an authorized partner to over 70 OCMs, Rochester monitors hundreds of product roadmaps and identifies lifecycle risks early. Our relationships include both fabless and vertically integrated OCMs, garnering a uniquely industry-wide perspective. In that way, Rochester can advise customers on component selection, inventory preservation, and risk mitigation in ways that individual OCMs cannot.

Case Study: NXP and TK Elevator

Proactive engagement is necessary because the obsolescence decision within an OCM occurs long before the customer receives an LTB notice. Rochester’s long-term manufacturing, die banking, and licensed production capabilities provide continuity. We acquire design data, test programs, and original wafers directly from OCMs, allowing them to continue manufacturing devices long after the original supplier exits.

For example, when NXP discontinued the P80C592 microcontroller, TK Elevator was in a major predicament (3). They relied heavily on this MCU for their elevator designs, and losing that component wouldn’t require re-engineering their control systems, incurring substantial costs and logistical delays.

Rather than accepting the discontinuation, the supply chain adapted through licensed manufacturing. Rochester Electronics intervened by acquiring the original design IP and test data directly from NXP. Assuming full responsibility for production, Rochester engineered, qualified, and manufactured a device identical in form, fit, and function to the original. Because the solution constituted a licensed replication using original specifications, it integrated with existing hardware and software without modification.

A Collaborative Way Forward

Industrial manufacturers need to recognize that, while they can’t dictate the direction of global semiconductor investment, they can strategically position themselves within the market. By aligning their BOMs with components meant for the automotive sector, industrial OEMs can realize a more stable lifecycle.

Partnering with Rochester helps OEMs translate that predictability into practical supply continuity. By maintaining 100% authorized inventory, preserving discontinued die, and replicating obsolete devices under license, Rochester provides industrial customers with a stable foundation in an otherwise unpredictable semiconductor landscape.

References

1. http://www.aecouncil.com/AECDocuments.html

2. https://www.iso.org/obp/ISO-26262-9:2011(en)

3. https://www.rocelec.com/news/thyssenkrupp-elevator-nxp-p80c592