Extending the pot life of silicones to several months: LEDs, 3D printing and beyond

How to extend the pot life of silicone without change in properties for applications in 3D Printing, LED lighting, LED backlights, and others

This article was first published on

www.techblick.comHow to extend the pot life of silicone to several months without changing its material properties? Ulrich Trog [Ulrich.Trog@joanneum.at | JOANNEUM RESEARCH] explains in this article how this is possible

JOANNEUM RESEARCH offers the formulation of the appropriate compound based on feasibility studies of the silicones used by its customers. Licences for the Supresil™ technology are available.

Platinum (Pt)-cured silicones are gaining in popularity, emphasising addition curing over traditional peroxide methods. This process ensures purity and efficacy, resulting in products with increased strength and superior aesthetics. The rise of Pt-curing marks a significant shift in silicone manufacturing techniques, promising unmatched quality and durability in a variety of applications. When crosslinking is initiated, the curing process starts almost immediately and the resulting silicone typically has a pot life limited to a maximum of a few hours at room temperature. This places significant practical and technological limitations on its use:

- short processing time

- anufacturing waste

- difficult reproducibility

- inflexible manufacturing process

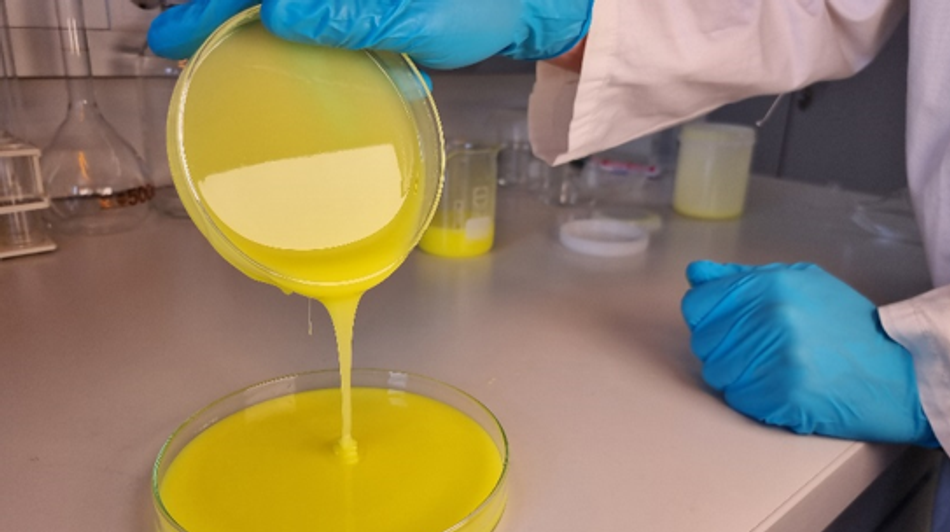

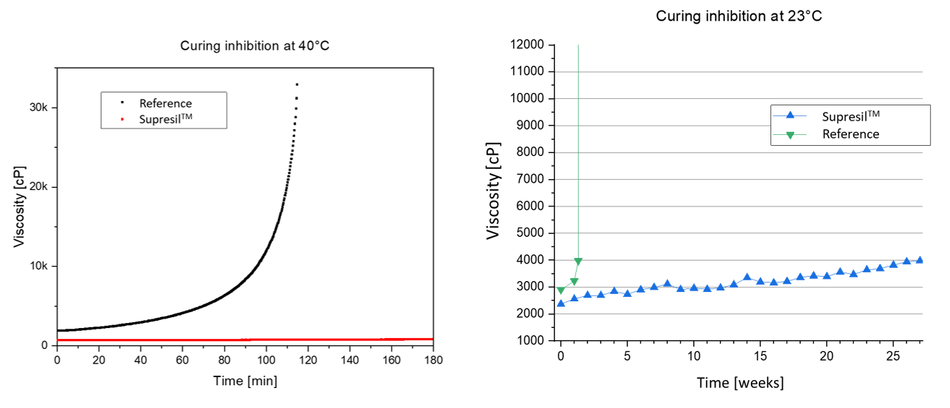

Our patented formulation greatly increases pot life via reversible inhibition of the crosslinking via hydrosilylation. After deposition, the inhibitors evaporate easily. Normal crosslinking occurs at mild temperatures, even below 80 °C, leading to a fast and complete curing.

Join the Future of Electronics RESHAPED event in Boston on 12 & 13 June 2024. Learn more https://www.techblick.com/electronicsreshapedusa

Benefits

- reduces production costs: the pot life of silicone mixtures can be extended to several months and beyond

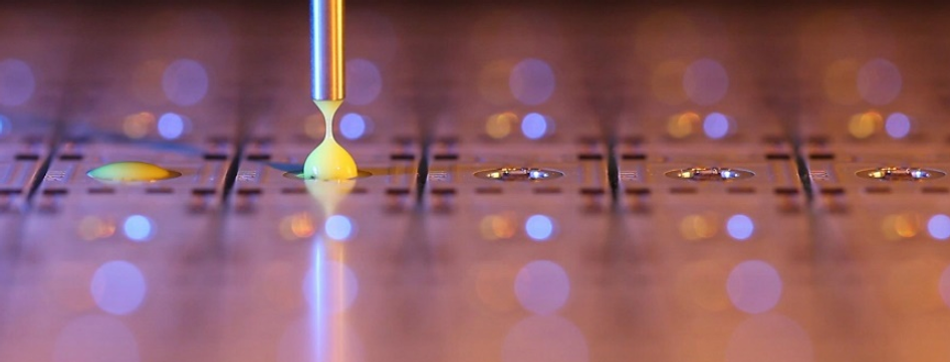

- enables (3D) printing: shelf stable, 1-component silicone inks can be formulated for use with a variety of printing processes including processes like dispensing, screen-printing, aerosoljet-printing, inkjet printing and others

- no change in material properties: through the complete and trace-free removal of the inhibitor during the curing process there is no change in the material or its properties

- applicable to liquid Silicone rubber (LSR) and high consistency rubber (HCR)

- suitable for all Pt-cure resins: no curing at processing temperature and normal curing at curing temperature, orthogonal with other inhibitors

- environmental: reduction in waste generation in production process

Application examples

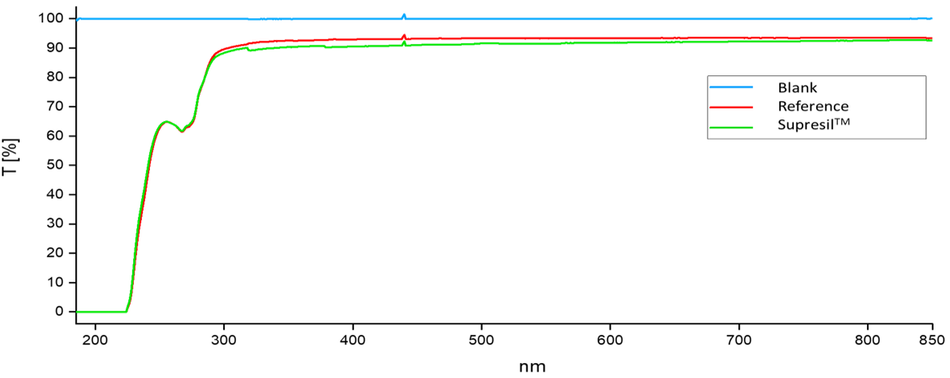

- LED production: Supresil™ resins reduce the processing efforts and increase the yield of colour conversion materials without changing their optical properties. The Supresil™ inhibited silicones can be mixed with colour conversion phosphors in large batches, increasing the accuracy and consistency of the colour conversion composites through improved wetting and distribution of the dispensed material and a better dispersion of the phosphors.

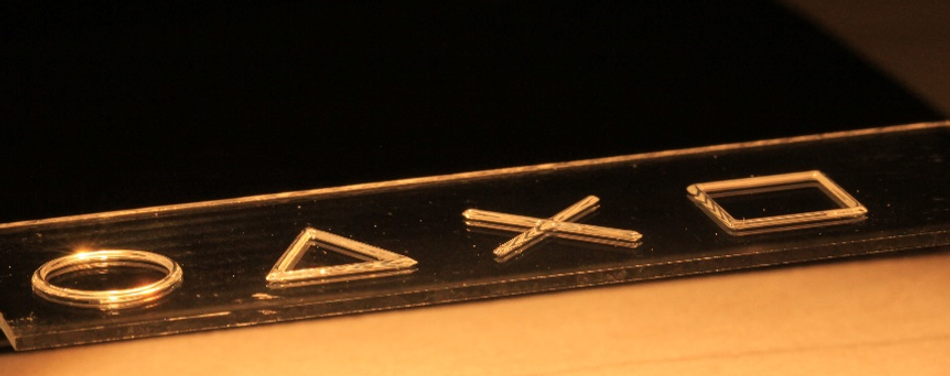

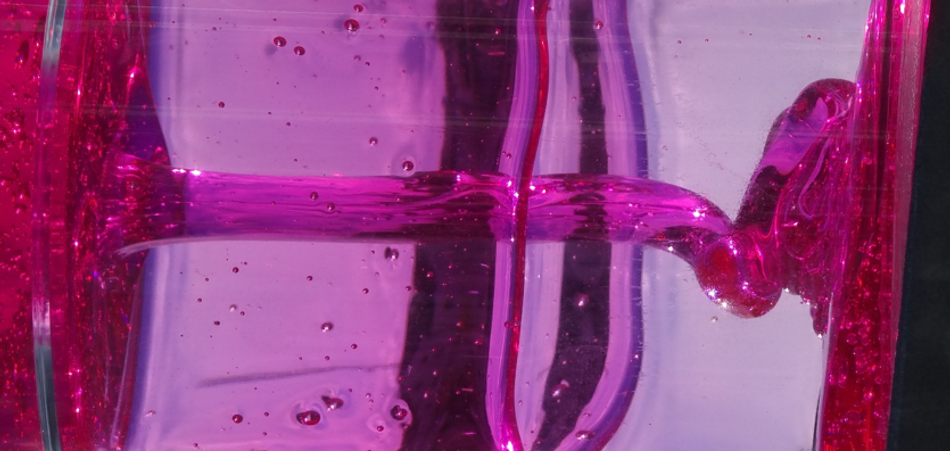

- 3D printing: Standard LSR formulations are optimised for extrusion and injection moulding machines and are not suitable for 3D printing. By adjusting the rheological behaviour and extending the pot life using JOANNEUM RESEARCH‘s proprietary reversible curing inhibition, 3D printing is now possible.

All material properties of the silicones are preserved (through complete and trace-free removal of the inhibitor):

- physical: shrinkage, Shore hardness, storage modulus

- optical: UV/VIS transmission, no „yellowing“, refractive index

- biocompatibility: relevant for medical grade resins / formulations

- unaltered production: viscosity, reproducibility

Fig. 1: Comparison of curing dynamics of standard silicone resins with SupresilTM inhibited resins

We are Exhibiting in Berlin! Come and visit our booth

Fig. 2: UV/VIS Transmission of cast silicones (100 µm) for the LED production

JOANNEUM RESEARCH is a publicly owned, Austrian Research and Technology Organisation. It is successful nationally and internationally in the fields of “Information and Production Technologies”, “Human Technologies and Medicine” and “Society and Sustainability”

AUTHOR: Ulrich Trog [Ulrich.Trog@joanneum.at |JOANNEUM RESEARCH]

All images: © JOANNEUM RESEARCH