Enhancing Medical Device Reliability with EMI Noise Suppression Devices by Murata

Murata EMI noise suppression devices help medical electronics maintain reliability, safety, and compliance by reducing high-frequency interference in compact high-power designs.

Medical electronics are growing more sophisticated as designers push for higher functionality in smaller, more portable form factors. Devices such as patient monitors and implantables now rely on dense power architectures and high-frequency switching regulators to deliver stable performance. This trend, however, poses a heightened risk of electromagnetic interference (EMI), which can directly affect patient safety, device reliability, and compliance with regulatory standards.

Unfortunately, as switching frequencies climb into the multi-megahertz range, traditional passives often struggle to maintain efficiency and thermal stability. Engineers, therefore, need novel techniques to balance miniaturization, power density, and noise suppression. In response, Murata has developed a new class of inductors and ferrite beads meant specifically for such compact, high-frequency environments.

EMI Challenges in Medical Devices

As medical systems evolve, power delivery networks have become both more compact and more complex. In portable imaging gear and implantable modules, for example, DC/DC stages now switch from a few megahertz up to ~100 MHz. Those higher frequencies sharpen transient response and can boost efficiency, but they also make the design more prone to EMI. Crosstalk and radiated emissions can couple into nearby sensitive circuits, degrade signal quality, or cause outright system errors. In low-voltage applications, voltage ripples become a significant concern as well.

Compact layouts exacerbate the problem. The drive toward thinner and lighter devices reduces the physical separation between noisy and sensitive subsystems, while multilayer boards concentrate routing density. This congestion makes medical electronics more susceptible to conducted and radiated EMI, which can impact wireless telemetry or sensor accuracy.

Reliability is further stressed by environmental factors, as medical devices are expected to deliver consistent performance across thermal ranges often as wide as -55 °C to +125 °C. In this context, power components have to deliver high current while keeping self-heating and voltage drop to a minimum, lest they risk thermal runaway or rail instability. To meet those demands, engineers specify passives with tightly controlled electrical parameters and mechanically robust construction.

All things considered, EMI suppression is tantamount to device uptime, patient safety, and regulatory compliance.

Frequency-Specific Beads for Noise Reduction and Increasing Receiver Sensitivity

Wireless functionality is now a standard and expected feature in medical electronics. To support multiple protocols and wavelengths, designers often incorporate multiple antennas into devices, each of which operates at a different frequency within the same enclosure. If designers don't implement proper isolation, noise can leak between antenna paths, reduce receiver sensitivity, and degrade overall communication reliability.

Frequency-Specific Beads by Murata, like the BLF and LQZ series, offer a solution to this challenge by providing targeted impedance peaks at key frequency bands. Murata specifically engineered these beads for frequency-selective suppression, precisely attenuating frequencies where interference is most likely to occur. Murata actively characterizes and measures their impedance at defined frequencies to guarantee consistent noise filtering performance across production.

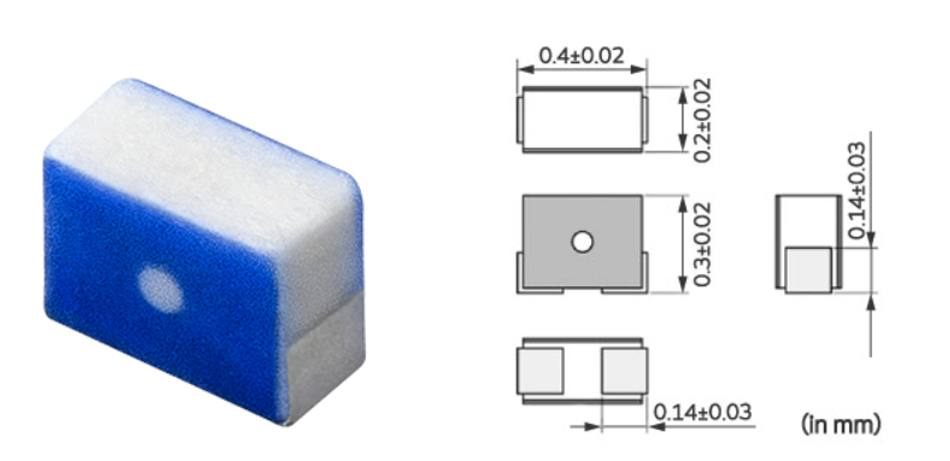

Available in ultra-compact 0201 and 01005 sizes, the BLF and LQZ beads are a great solution for high-density wireless modules and compact medical systems. By suppressing unwanted coupling and isolating high-frequency signal paths, they help designers maintain clean RF environments and maximize receiver sensitivity. Ultimately, designers can use them to improve the accuracy and reliability of wireless medical communication systems.

High-Current Ferrite Beads for Noise Suppression

While inductors help manage switching behavior inside converters, ferrite beads clean up the power rails that feed sensitive subsystems. In medical electronics, such as imaging sensors, conducted noise or voltage ripple can be detrimental to results. The challenge is that modern designs require higher currents while still operating within the strict thermal and voltage limits required for safety.

Ferrite beads meet this need by presenting high impedance to high-frequency noise while maintaining very low resistance to DC. BLM and BLE series ferrites at Murata are specifically engineered for this balance. With DC resistance values as low as 0.6 mΩ, they minimize voltage drop under high-load conditions and guarantee stable operation for downstream circuits. At the same time, their impedance profiles are tuned to block the switching noise generated by multi-MHz DC/DC converters.

Available in compact sizes ranging from 0603 to 1206, the BLM and BLE beads can be integrated directly into dense layouts. BLM ferrite beads are even more compact and are offered in the smallest 01005 size. Both are rated for -55 °C to +125 °C operation and provide consistent performance in even the most extreme medical environments.

The merit of BLE series ferrite beads is consistent performance across any applied input current, where BLM series impedances change based on the applied current. BLE are not direct replacements for BLM across the board, but engineers value the performance of BLE series where they are needed and can be applied.

Added more information about BLE series because their strong point is consistent impedance over a wide range of applied input currents - this is what separates BLE from BLM series, but they are not interchangeable. BLE series are typically specific-case uses that engineers usually recognize.

Design Flexibility

No two medical devices share the same design constraints. Portable monitors need low-profile passives to fit within slim housings, while implantable systems need long-term reliability under strict thermal and electrical limits. Aware of this diversity, Murata offers inductors and ferrite beads that can be adapted beyond standard catalog specifications.

By engaging early with Murata, medical OEMs can co-design solutions that reduce EMI risk, conserve board space, and extend device operating life.

Conclusion

As devices shrink and workloads increase, clean rails and tight control of coupling move to the top of the designer’s checklist. As a result, noise suppression is important and synonymous with tighter PCB layouts. Offering a wide range of EMI solutions, from high-current ferrite beads, frequency-specific ferrite beads, and high-performing BLE series, Murata gives engineers the components necessary to navigate multiple design and noise challenges with ease.