Early Fault Detection in Lithium-ion Batteries with Honeywell BES LITE

As lithium-ion batteries power more vehicles and energy systems, the risk of thermal runaway grows. Honeywell's BES LITE detects electrolyte vapors at the first vent stage, enabling rapid intervention to prevent failures, protect assets, and ensure safety compliance.

Executive Summary

The rapid adoption of lithium-ion (Li-ion) batteries in electric mobility, renewable energy storage, and portable power systems has transformed industries with their high energy density and long service life. However, these same advantages bring a critical safety challenge: the risk of thermal runaway, a chain reaction triggered by abuse, defects, or degradation that can lead to fires, explosions, and significant loss of assets or life.

Traditional monitoring methods often detect danger late in the failure sequence, leaving little time to respond. The most effective safety strategies identify the earliest and most reliable indicators of failure, enabling intervention before escalation. Honeywell’s Battery Safety Electrolyte Detector (BES LITE) addresses this need by selectively detecting electrolyte vapors released during the initial cell venting stage, typically 5 to 15 minutes before thermal runaway.

Powered by Honeywell’s proprietary electrochemical sensing technology, BES LITE delivers an early, accurate alert while avoiding false positives. Its compact, low-profile, and intrinsically safe design integrates easily into battery energy storage systems (BESS), aerial mobility platforms, micro-mobility platforms, residential & portable batteries.

By combining early detection, environmental durability, and simple integration, BES LITE enables battery manufacturers to safeguard assets, protect lives, meet regulatory requirements, and reduce total ownership costs, providing a decisive safety and business advantage in today’s electrified world.

The Growing Importance of Battery Safety

Lithium-ion (Li-ion) batteries have become the backbone of modern electrification, powering electric vehicles (EVs), micro-mobility platforms, renewable energy storage systems, and a growing range of industrial and consumer applications. Their appeal lies in their high energy density, long cycle life, and ability to deliver sustained power in compact, lightweight formats. However, these same attributes make them vulnerable to catastrophic failure when damaged, improperly managed, or subjected to extreme conditions.

The risks are well documented. Incidents of battery fires in electric vehicles, energy storage facilities, and consumer devices have been widely reported in recent years, prompting product recalls, regulatory scrutiny, and public safety concerns.[1] In the energy storage sector, high-profile fires in large-scale Battery Energy Storage Systems (BESS) have highlighted the difficulty of containing thermal runaway once it begins, particularly in densely packed, high-capacity modules. For mobility applications, such events can have severe consequences for passenger safety, brand reputation, and operational continuity.

Market trends are amplifying the urgency for advanced safety measures. Global EV sales exceeded 14 million units in 2023 and continue to grow year over year.[2] Similarly, the global BESS market is expected to grow at a compound annual growth rate (CAGR) exceeding 25% over the next decade, driven by renewable integration and grid modernization.[3] As the installed base of li-ion systems grows, so does the statistical probability of failures, even in well-designed systems.

Regulatory bodies and industry standards are responding accordingly. Standards such as UL 1973, IEC 62619, and ISO 6469-1 mandate strict performance and safety requirements, covering electrical, thermal, and mechanical abuse conditions. Compliance is not only a legal necessity but also a commercial advantage, as safety certifications can influence purchasing decisions, insurance premiums, and market acceptance.

In this context, early and accurate detection of cell failure precursors, particularly electrolyte vapor emissions, has emerged as a critical safety strategy. Unlike temperature or voltage monitoring, which may signal danger only seconds before runaway, detecting electrolyte vapors during the first vent stage provides a valuable window for mitigation actions. Technologies like Honeywell’s Battery Safety Electrolyte Detector (BES LITE) directly address this need, offering a path to enhanced safety without compromising space, weight, or integration complexity.

Understanding Thermal Runaway

Lithium-ion battery cells are susceptible to various types of abuse, which can be categorized as electrical, thermal, or mechanical. Such abuses may result from practices like overcharging, overheating, defects during manufacturing or physical abuse. These issues can induce internal short circuits or cause an increase in the internal temperature of the cell.

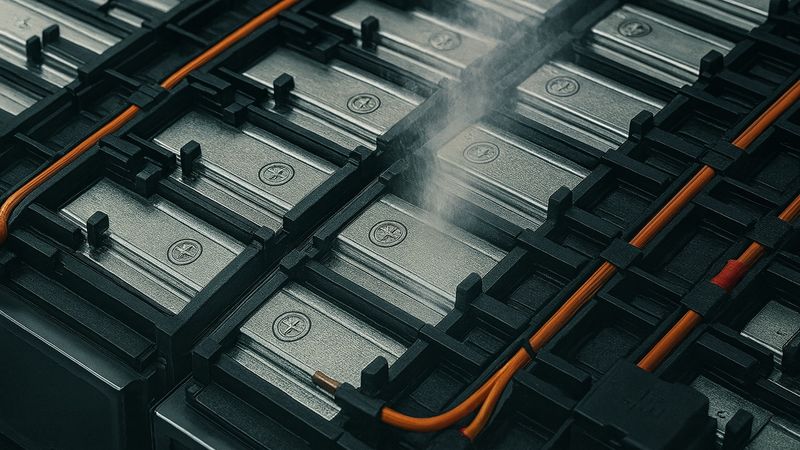

Thermal runaway in lithium-ion batteries occurs when an increase in internal temperature leads to gasification of the electrolyte, resulting in pressure build-up. This escalation ultimately causes the separator to melt, creating a short circuit that ignites gases and initiates an intense fire.

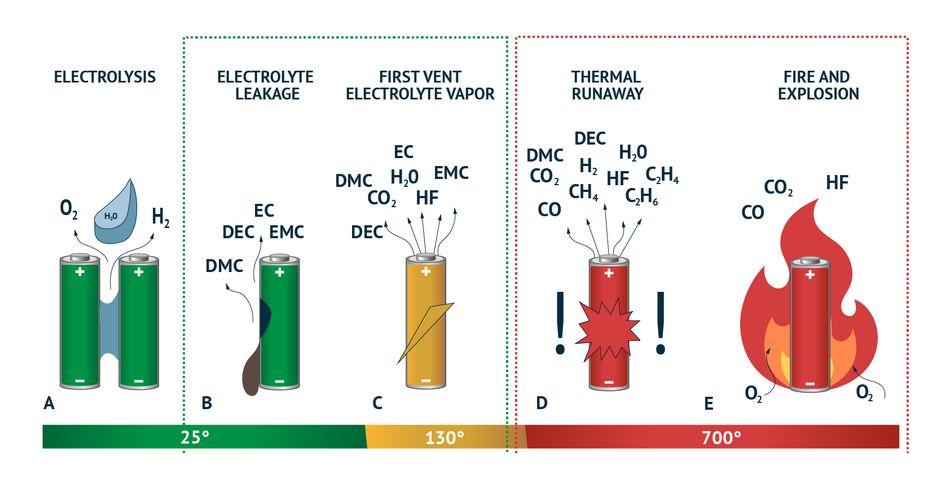

The progression typically follows these stages:

Abuse or defect: Mechanical damage, overcharging, internal short circuits, or exposure to high temperatures initiates localized heating.

Electrolyte leakage: Rising temperatures vaporize the liquid electrolyte between the anode and cathode, increasing internal pressure.

First vent: Pressure causes the cell vent to rupture, releasing electrolyte vapor into the surrounding environment.

Thermal runaway: If the heating continues, internal chemical reactions accelerate uncontrollably, raising temperatures to several hundred degrees Celsius.

Fire and explosion: The runaway process can ignite flammable materials within the cell, producing flames, and sometimes fire and explosion as well.

The first vent stage offers the earliest and most reliable opportunity for intervention. During this phase, gases such as ethyl methyl carbonate (EMC), diethyl carbonate (DEC), dimethyl carbonate (DMC), ethylene carbonate (EC), and propylene carbonate (PC) are released. These are signature components of li-ion electrolytes and are largely absent in normal operation, making them highly selective indicators of cell failure.

The first vent event can occur 5 to 15 minutes before thermal runaway, depending on the abuse type, state of charge, and battery design. This time window can mean the difference between a controlled shutdown and catastrophic damage. Removing the source of abuse (such as external heating or charging) at this stage has been shown to arrest the progression to runaway entirely in some cases.

Traditional safety monitoring relies heavily on temperature, voltage, and current sensors, which often trigger alarms only seconds before runaway, leaving little time for mitigation. In contrast, electrolyte vapor detection provides a deterministic signal that directly correlates with impending thermal runaway.

By focusing on this early warning signature, technologies like Honeywell’s BES LITE enable timely protective actions, such as isolating the affected module, alerting operators, or shutting down the system, greatly enhancing both asset protection and user safety.

Honeywell BES LITE for Early-Stage Battery Fault Detection

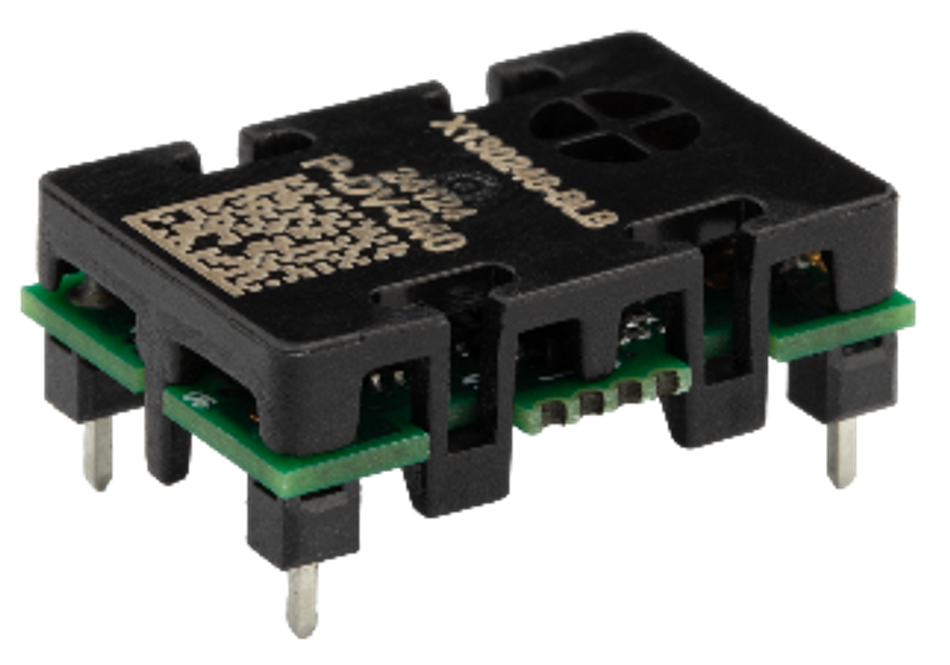

Honeywell’s BES LITE series is purpose-built to address the critical early-warning gap in li-ion battery safety monitoring. Unlike conventional gas or temperature sensors, BES LITE uses proprietary electrochemical sensing technology to selectively detect the electrolyte vapors released during a cell’s first vent stage, providing actionable warning several minutes before thermal runaway begins.

At the core of the BES LITE’s performance is its selective sensitivity to specific carbonate-based electrolyte compounds, including EMC, DEC, DMC, EC, and PC. This selectivity virtually eliminates false positives from other gases that may be present in industrial or automotive environments. When the sensing element is exposed to a predetermined concentration of electrolyte vapor, the device’s output voltage shifts instantly from a nominal 2.5 VDC to 5.0 VDC, signalling a first vent event. If a device fault is detected or power is lost, the output drops to 0 VDC, enabling integrated diagnostics and fault management.

BES LITE is chemistry-agnostic, functioning effectively with common li-ion chemistries including nickel manganese cobalt oxide (NMC), lithium iron phosphate (LFP), and lithium titanate oxide (LTO). It is also compatible with prismatic, pouch, and cylindrical cell formats, providing flexibility for use across industrial and aerospace battery architectures.

Parameter | Value |

Detection principle | Electrochemical sensing |

Detected media | EMC, DEC, DMC, EC, PC |

Startup time | 1 second to valid output |

Response time | < 2 seconds (typical) |

Output type | Three-state analog output |

Output voltage levels | 2.5 V (normal), 5.0 V (vent detected), 0 V (fault/no power) |

Supply voltage | 4.5 V to 5.5 Vdc |

Current consumption | < 3 mA |

Operating temperature | -20°C to 70°C |

Storage temperature | -40°C to 85°C |

Humidity | 10% to 90% RH (non-condensing) |

Ingress protection | IP30 (BES LITE) |

Operating life | ≥ 10 years |

Storage life | ≥ 3 years |

Weight | 4.5 g (BES LITE) 2.5g (BES LITE-BM) |

Dimensions (W × L × H) | 31.8 × 23.5 × 9.9 mm (BES LITE) 21 × 14 × 9.5 mm (BES LITE-BM) |

BES LITE Variants

The BES LITE series is available in two versions:

BES LITE (BESL-10100-000): Suitable for installation at any desired location within a battery pack

BES LITE-BM (BESL-20200-000): Suitable for space-constrained applications and direct board-mount installation

Both variants share the same sensing technology and detection capabilities, allowing system designers to choose the appropriate form factor without compromising performance.

Considerations |  BES LITE |  BES LITE-BM |

Installation Method | Mounts via screws | Directly mounted on Printed Circuit Board Assembly (PCBA) |

Space Requirements | Requires additional space for screws and mounts | Space-efficient footprint |

Flexibility in Installation | Allows installation at any desired location | Allows installation on BMS |

Cost Implications | Requires cable harness at installation | No cable harness required. Lower assembly costs |

By combining compact size, low power draw, and robust environmental tolerance with unmatched selectivity for battery electrolyte vapors, Honeywell’s BES LITE delivers the kind of deterministic early-warning signal that designers and safety engineers need to prevent thermal runaway before it starts.

Key Features

Avoiding false alarms: By targeting only EMC, DEC, DMC, EC, and PC vapors, the sensor minimizes false positives and ensures alarms are triggered only during genuine cell venting events.

Three-state analog output: Outputs a clear, deterministic signal: normal operation at 2.5 V, vent detected at 5.0 V, and fault/no power at 0 V. This straightforward interface allows direct integration with battery management systems (BMS) or safety controllers, reducing software complexity and enabling fast decision-making.

Fast response: Activates within one second of power-on and typically detects electrolyte vapor in less than two seconds after the gas reaches the sensor. This rapid response maximizes the available time for operators to implement mitigation strategies, such as isolating affected modules or initiating protective shutdowns.

Intrinsically safe design: Operates without an internal heating element, eliminating a potential ignition source. This makes it ideal for use in flammable environments and explosion-proof enclosures where safety is critical.

Low-profile form factor: With BES LITE measuring just 31.8 × 23.5 × 9.9 mm and weighing only 4.5 g while BES LITE-BM measuring just 21 x 14 x 9.5 mm and weighing only 2.5 g, the sensor can be installed in tight spaces within battery packs, including micro-mobility and aerospace applications where size and weight constraints are stringent.

Long operational life: Rated for over 10 years of service under ambient operating conditions, BES LITE reduces maintenance requirements and supports long-term reliability.

Rugged environmental performance: Functions reliably across a wide operating temperature range (-20°C to 70°C), withstands vibration up to 8 g and shock loads of 50 g, and complies with automotive EMC standards (AIS 004 Part 3). This ensures consistent performance in harsh real-world environments.

Immunity to contaminants: Highly resistant to siloxane poisoning, cross-gas interference, and common airborne contaminants, making it suitable for mission-critical applications where dependable operation is non-negotiable.

Integration

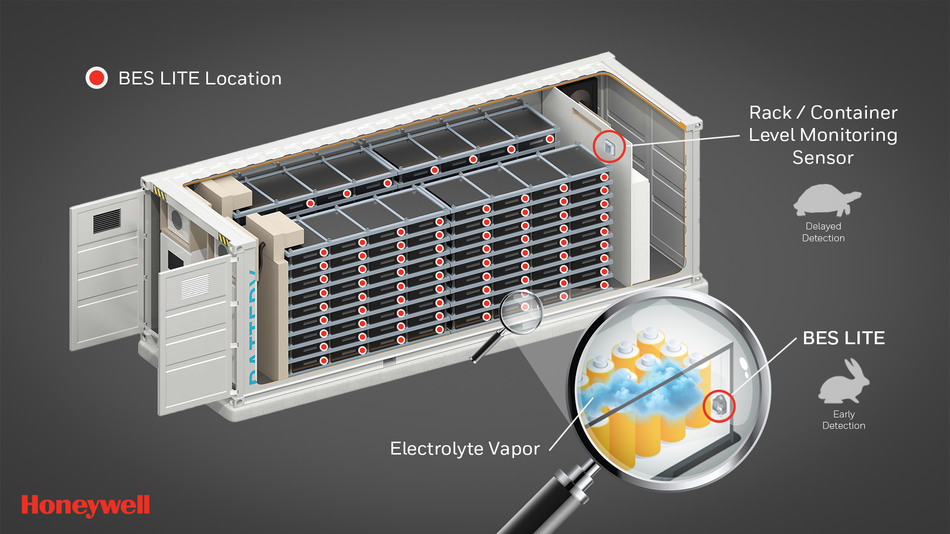

The BES LITE series is designed for seamless integration into both new and existing lithium-ion battery systems, allowing for early detection of thermal events without significant redesign. One sensor per pack (validated for a free volume of 30 litres) effectively identifies electrolyte vapor at its source, often before temperature sensors react.

Applications Across Industries

The versatility of the BES LITE series allows it to be deployed across a wide spectrum of li-ion battery applications such as:

Battery Energy Storage Systems (BESS): In large-scale grid or behind-the-meter storage installations, a single thermal runaway incident can cause extensive damage and prolonged outages. BES LITE offers pack-level monitoring that complements rack or container-level detection, ensuring thermal events are identified at their source. Early detection provides operators with the opportunity to isolate affected units and prevent cascading failures.

Urban Air Mobility (UAM) and Unmanned Aerial Vehicles (UAVs): In aerospace applications where weight, volume, and safety margins are critical, BES LITE’s low mass (4.5 g / 2.5 g) and compact footprint are decisive advantages. Early detection can enable flight control systems to initiate emergency procedures before a battery issue compromises mission safety.

Micro-Mobility and Portable Power Systems: Electric scooters, motorcycles, and portable generators often have tightly packed battery modules with limited room for additional components. BES LITE’s small form factor and low power draw make it ideal for these space- and energy-constrained environments.

Light Industrial and Specialty Equipment: From forklifts and material handling systems to lawnmowers and construction equipment, BES LITE provides a straightforward means of enhancing battery safety without extensive redesign. Its compatibility with different battery chemistries and rugged environmental performance ensures consistent reliability in diverse operating conditions.

Business and Operational Impact

Incorporating BES LITE into li-ion battery systems delivers benefits that go beyond safety, driving efficiency, reducing costs, and strengthening market competitiveness.

Lower Total Cost of Ownership: Early vent detection helps prevent costly failures, downtime, and asset loss, delivering long-term savings.

Enhanced Asset Protection: Isolating affected modules upon receiving BES LITE alert can help mitigating thermal runaway, potentially safeguarding the BESS, and industrial systems.

Compliance and Certification Support: Supports adherence to various safety standards, easing market entry and certification.

Brand and Customer Confidence: Demonstrates leadership in safety, reinforcing trust and market reputation.

Insurance and Risk Reduction: Can improve insurability and reduce liability exposure by lowering the risk of catastrophic events.

Faster Time-to-Market: Compact design and straightforward integration reduce engineering effort for new product launches.

Conclusion

As electrification accelerates, li-ion batteries are powering transportation, energy storage, and industrial applications worldwide. Alongside their benefits come safety risks that require proactive management. Honeywell’s BES LITE addresses this need with selective electrolyte vapor detection during the first vent stage, providing a 5-15 minute early-warning window to intervene and prevent thermal runaway.

With its compact size, robust design, long service life, and compatibility across chemistries and form factors, BES LITE integrates seamlessly into BESS, aerospace, micro-mobility, and industrial systems. It enables enhanced safety, supports compliance, reduces costs, and reinforces trust in safety-critical markets.

Learn more about Honeywell’s solutions at TTI.

References

[1] National Highway Traffic Safety Administration. Consumer Alert: GM Expands Recall, All Chevrolet Bolt Vehicles Now Recalled [Internet]. Washington, DC: NHTSA; 2021 Aug 20. Available from: https://www.nhtsa.gov/press-releases/recall-all-chevy-bolt-vehicles-fire-risk

[2] International Energy Agency. Global EV Outlook 2024: Trends in electric cars [Internet]. Available from: https://www.iea.org/reports/global-ev-outlook-2024/trends-in-electric-cars

[3] Persistence Market Research. Energy Storage Systems Market Size, Share, Growth, Trends, Forecast, 2025 - 2032 [Internet]. 2025 Apr 23. Available from: https://www.persistencemarketresearch.com/market-research/energy-storage-systems-market.asp