Driving Industrial Automation Forward with SBCs

Exploring the advanced features of SBCs in optimizing control and industrial efficiency

Exploring the advanced features of SBCs in optimizing control and industrial efficiencyAutomation is becoming a transformative trend in the constantly evolving industrial landscape. Industrial automation, which involves implementing control systems based on computers and robots, is remodeling industrial operations, ranging from the production line and manufacturing to quality control and material handling. In this context, the Single Board Computer (SBC), a discrete but powerful engineering component, is emerging as a driving force behind this revolution.

Boosting efficiency and control with SBCs in industrial automation

SBCs play an important role in industrial automation, significantly boosting cutting-edge applications. These compact devices, equipped with built-in microprocessors, memory, and input/output (I/O) interfaces, have become key to various innovative industrial applications.

Industries widely use SBCs to monitor and control production lines, regulate environmental conditions, and supervise machine operation. An application example of SBCs is accurately monitoring temperature and humidity conditions in storage environments for perishable products. Sensors connected to the SBCs collect data in real time, allowing precise control over storage variables. This level of monitoring provides an ideal environment for preserving perishable products, avoiding waste, and ensuring the quality of the end product.

Similarly, in the pharmaceutical sector, SBCs can play an important role in process automation. For example, a pharmaceutical company can implement SBCs to accurately monitor the dosage of chemical products in its manufacturing procedures. Dosing sensors connected to SBCs ensure that the exact amounts of chemicals are added to each production batch, assuring the consistency and quality of pharmaceutical products.

In manufacturing plants, SBCs can ensure the continuous operation of the production line, without requiring downtime for maintenance, by enabling predictive maintenance. Furthermore, SBCs can use tracking and logistics systems to help monitor the movement and location of products in real time along the supply chain.

Additionally, the SBCs contribute to interface human-machine interaction (HMI). These compact computers can feed information to industrial displays and touch screens, providing operators with critical real-time information about the manufacturing process. SBCs can also be programmed to facilitate automatic corrective actions, minimizing the need for constant human intervention.

Benefits and technical challenges of SBCs for industrial automation

The adoption of SBCs in industrial automation brings with it many tangible benefits. They offer significant cost efficiency, providing a compact and economical alternative to conventional Programmable Logic Controllers (PLCs) or Programmable Automation Controllers (PACs) without compromising functionality.

SBCs provide flexibility in applications due to their ability to run various operating systems, such as Ubuntu, Debian, and Android. In addition, they support different programming languages, such as Python, C, and C++, making them highly adaptable to the multifaceted demands of industrial automation. Their compact footprint and reduced energy consumption make them versatile for industrial applications where space optimization and energy efficiency are paramount requirements.

However, the use of SBCs in industrial automation faces technical challenges. Industrial environments often require high standards of durability and reliability, which conventional consumer SBCs may need to meet. Ensuring robustness against temperature extremes, vibrations, and electromagnetic interference requires additional hardware design considerations or the selection of industrial-grade SBCs.

Industrial automation with OKdo’s ROCK series

OKdo's ROCK series SBCs have high-performance processors, such as those based on the ARM architecture, giving them the processing power needed to tackle complex automation tasks. Additionally, their durability is ensured through a robust design that can cope with extreme temperature fluctuations, strong vibrations, and electromagnetic interference.

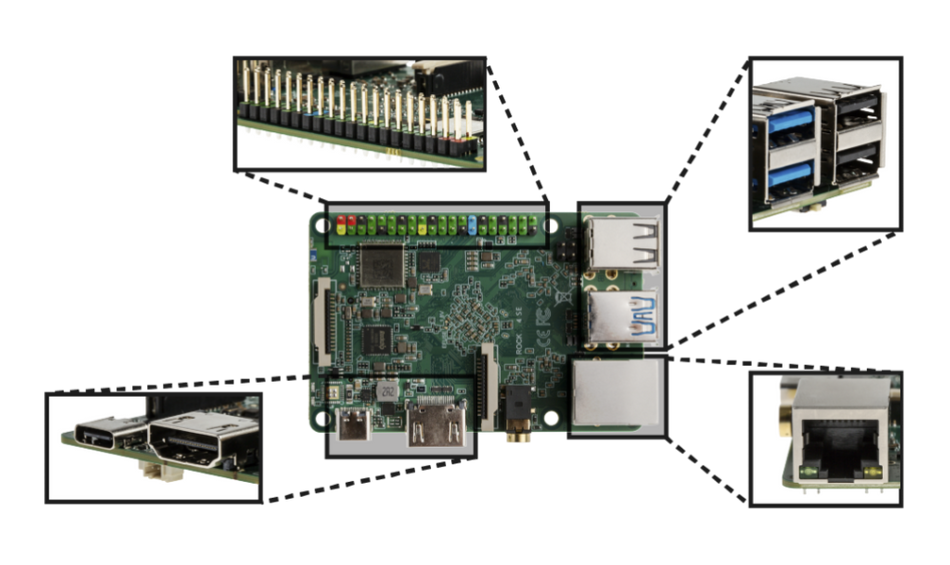

The ROCK series also features connectivity with Ethernet interfaces and support for wireless communications such as Wi-Fi and Bluetooth, enabling comprehensive integration into modern industrial networks. Expansion flexibility is extended through GPIO ports and slots for expansion modules, providing precise and adaptable customization for various industrial applications. In industrial automation, the ROCK series SBCs can be used, for example, in robotic control systems and preventative maintenance.

Robotic control systems

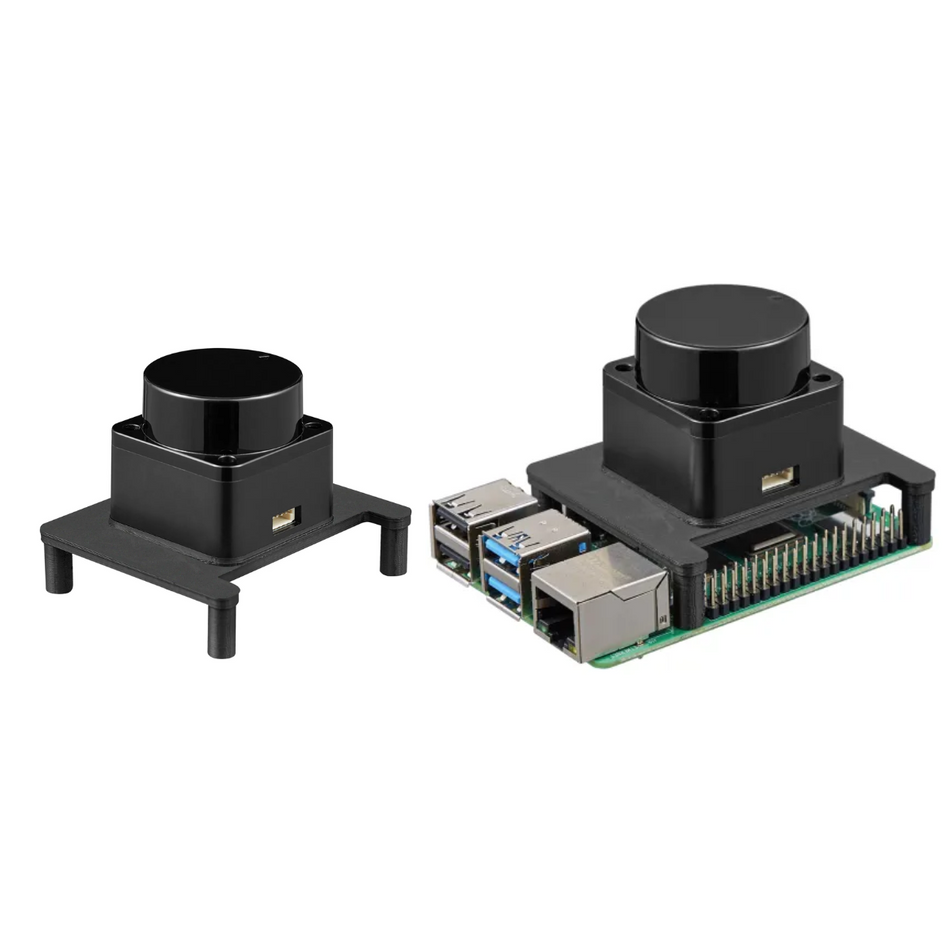

In industrial automation with robots, an example of an SBC application is the ROCK 4 SE combined with a LiDAR module. Combining these two devices enables the robot to detect nearby objects accurately, providing positioning data for navigation in the industrial landscape. Therefore, using an efficient and low-cost system, the robot can perform its functions accurately.

The ROCK 4 SE is an SBC developed by OKdo in collaboration with Radxa, based on a low-energy, high-performance Rockchip RK3399-T Hexa-core processor. It is equipped with Processador Hexa-core com big.LITTLE™ Arm® Dual Cortex-A72® CPU , Quad-core Cortex-A53 e Arm Mali™ - GPU T860MP4 and 4GB 64bit LPDDR4 RAM. ROCK 4 SE also offers ample storage capacity with a Micro SD card, an eMMC card, and an M.2 card. The eMMC storage gives ROCK a significant advantage in embedded designs due to eMMC's superior speed, reliability, capacity, and durability over SD cards.

Additionally, it has various connectivity features, including Bluetooth 5.0, WiFi, Gigabit Ethernet, USB and HDMI ports, and an integrated antenna, allowing you to incorporate the ROCK 4 SE into applications widely. The ROCK 4 SE also has the following features for the 40-pin 0.1" (2.54 mm) header it supports a wide range of interface options:

2 x UART

2 x SPI bus

2 x I2C bus

1 x PCM/I2S

1 x SPDIF

1 x PWM

1 x ADC

6 x GPIO

2 x 5V DC power in

2 x 3.3V power pin

The LiDAR Module is a time-of-flight (TOF) sensor that uses a laser to detect distances up to 12 meters away with an accuracy of 0.02 mm. It offers 360-degree environmental detection and is compatible with the SBC ROCK 4 SE through a UART cable, making it ideal for industrial applications such as robot movement control and precise mapping of the industrial environment.

Automated preventative maintenance

In preventative maintenance of industrial processes, SBCs also are applicable, preventing breakdowns and downtime, saving money, and increasing production efficiency. In such applications, the system typically consists of an SBC to receive, process, and transmit the measured data.

An SBC model that can create an automated preventive maintenance system is the ROCK 4 Model C+, a robust, high-performance multifunction board based on the powerful Rockchip RK3399-T SoC. This SBC includes a Dual Arm Cortex A72 CPU, Quad Arm Cortex A53, and Arm Mali T860MP4 GPU and is compatible with a wide range of software operating systems, such as Android and Linux, with the GPU being Al stack-enabled, such as Caffe, a deep learning framework.

The ROCK 4 C+ provides serial communication capabilities, ethernet and USB connections, and a wireless connection compatible with 2.4 GHz/5 GHz WiFi networks. Furthermore, this SBC can perform safe shutdowns at the touch of a button without the risk of corrupting storage due to the integrated on/off button.

One example of preventive maintenance is in rotating machines in industrial processes such as food refrigeration. A failure prevention system can be built to maintain these rotating machines by monitoring and identifying the current operating state. A system comprising the following components can be implemented:

A ROCK 4 C+ to receive, process, and transmit the measured data.

A platform for monitoring the operational status, such as ThingSpeak, where a display can be connected to the ROCK to show the information.

An LSM9DS1 module to detect vibrations.

A voltage sensor compatible with the industrial network's maximum voltage, an example of 500V, is the V500-ISO sensor.

A current sensor that supports the machine's operating current, for example, the HTP200-P sensor that measures currents up to 200A.

Additionally, a dataset is a requirement to train AI algorithms, such as recurrent neural networks. This is crucial for recognizing operational status and predicting failures of the rotating machines. With this in place, the monitoring system can alert the maintenance team in case of any issues, and the AI algorithm and device configurations can work seamlessly together.

Conclusion

SBCs are an efficient, innovative, and flexible solution for industrial automation. Their potential is transformative for the future of automation, despite any challenges that may arise. Using the ROCK family, you can access low-cost SBCs, such as the ROCK 4 SE and ROCK 4 C+, that offer reliability and high performance.

References

OKdo. “How to build an autonomous industrial robot with ROCK 4 SE & LiDAR Module”

Fernando Brügge, 2021. “The rise of industrial AI and AIoT: 4 trends driving technology adoption”

Cassiano Ferro Moraes, 2023. “How SBCs can lead the way to predictive maintenance”