Designing Reliable Current Sensing Circuits: Key Tips from ROHM Semiconductor

Accurate current measurement is essential for enabling control, ensuring protection, & improving power efficiency in EVs, energy systems, industrial machinery, and a wide range of applications. ROHM solutions deliver the precision, stability, & noise immunity required for reliable current sensing.

Power, Safety, and Control Begin with Current Sensing

The importance of current sensing in modern electronics has grown rapidly alongside the demand for energy efficiency, safety, and reliable control. From electric vehicles and battery management systems to renewable energy and industrial automation, precise current measurement governs how power is managed, faults are detected, and systems remain protected. As operating voltages rise and currents increase, challenges such as thermal stress, electrical noise, and material aging make accuracy and long-term reliability essential design goals.

This article outlines the key considerations for building high-precision current sensing circuits. It explains the major sensing methods, examines how resistor and amplifier selection shape accuracy, and highlights the role of noise immunity in ensuring stability. The discussion concludes with practical component solutions that translate these principles into circuits capable of withstanding the demands of real-world applications.

Types of Current Sensing Methods

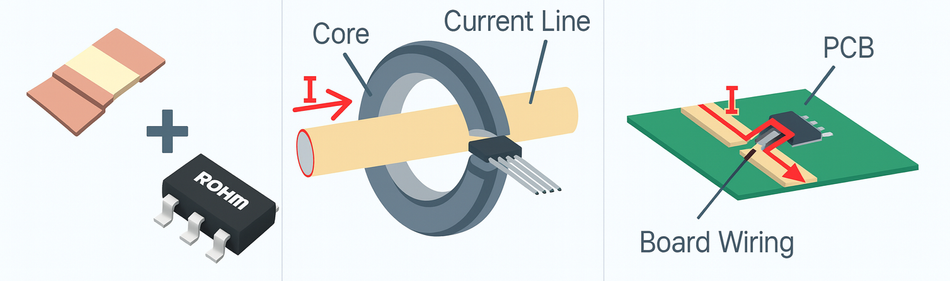

There are several ways to measure current, but two approaches dominate most circuit designs: resistive and magnetic sensing.

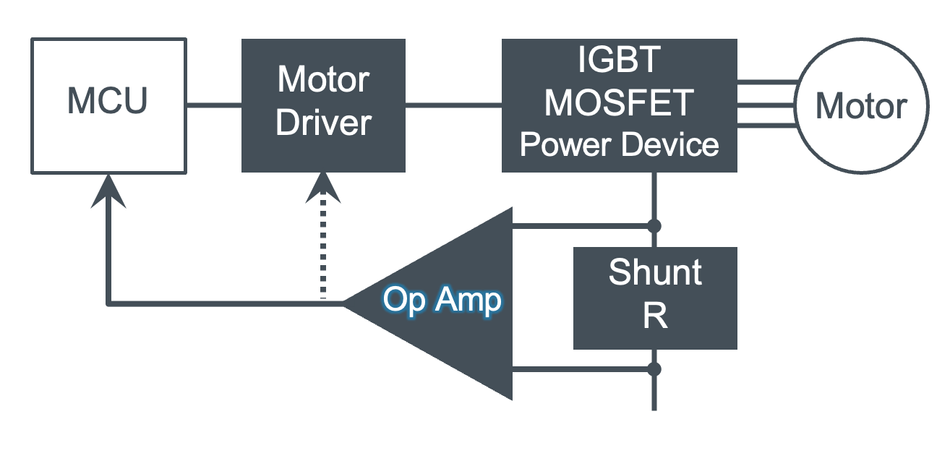

In the resistive method, a shunt resistor develops a small voltage proportional to the current. This voltage is then amplified using either a general-purpose Op Amp or a dedicated current sense amplifier (CSA), depending on the design needs. The approach is cost-effective, offers design flexibility, and delivers good accuracy at moderate currents. However, it introduces some heat loss through the shunt resistor, which must be managed in higher-current applications.

Magnetic sensing, by contrast, measures the magnetic field generated by current flow using Hall or xMR sensors. It avoids power loss and allows non-contact measurement but is more susceptible to external magnetic interference and can be bulkier.

Other sensor types exist, such as integrated current sensor ICs. They combine sensing elements and signal conditioning in a single package, offering compactness and ease of integration, but are typically used in space-constrained or specialized applications.

Table 1: A comparison of current sensing methods

Category | Op Amp | CSA | Core Type | Retractable Type (Coreless) |

System | Non-isolated | Non-isolated | Isolated | Isolated |

Principle | Amplify voltage drop across shunt resistor | Amplify voltage drop across shunt resistor. Suitable for low current values. | Detect magnetic field at core | Draw current into IC and detect magnetic field |

Typical Measurement Range | ~300 A | ~300 A | ~2000 A | ~50 A |

Features | Low cost, high design freedom, heat generation (shunt) | Easy to design, fewer components | No heat generation, non-contact, 3D mounting | Surface-mount, compact, affected by external magnetic fields |

Main Parts | Op Amp, Shunt Resistor, Gain Resistor | CSA, Shunt Resistor | Magnetic Sensor (Hall/xMR), Core | Current Sensor IC |

A Single Resistor Can Make or Break Circuit Reliability

In resistive current sensing, the shunt resistor sets the baseline for accuracy; any deviation directly impacts system performance. A poor selection can shift error margins by entire percentage points, leading to false protections or missed faults.

Factors to Consider During Selection:

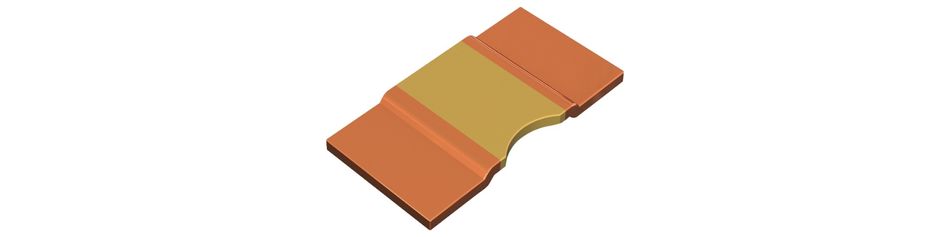

Material: Metal plate resistors generally offer better thermal cycling durability and lower temperature coefficient of resistance compared to thick film types, making them more reliable in demanding environments.

Mounting and Size: Smaller packages are more prone to mechanical stress. The length of the resistor plays a key role in absorbing thermal expansion and reducing solder fatigue.

Long-Term Aging: For automotive and industrial use, sulfur resistance, terminal robustness, and mechanical durability are essential to maintain accuracy over time.

“Treating a shunt resistor as ‘just a passive’ is how good designs go bad.”

Amplifier Choice Shapes Your Design Outcome

While the shunt resistor defines the sensing baseline, the amplifier determines how accurately that voltage is processed and interpreted. Op Amps provide full flexibility, allowing engineers to set gain and add filtering or protection circuits externally. This approach is suitable when fine-tuning is required or when the circuit must adapt to varying operating conditions.

“Noise doesn’t just distort signals; it sabotages decisions.”

CSAs, in contrast, integrate tightly matched internal gain resistors, reducing variation and improving measurement consistency. Their high input impedance allows external filtering with minimal impact on gain accuracy. CSAs are also well-suited for low current sensing, where accurate amplification of small shunt voltages is critical.

Noise Immunity: The Hidden Factor in System Stability

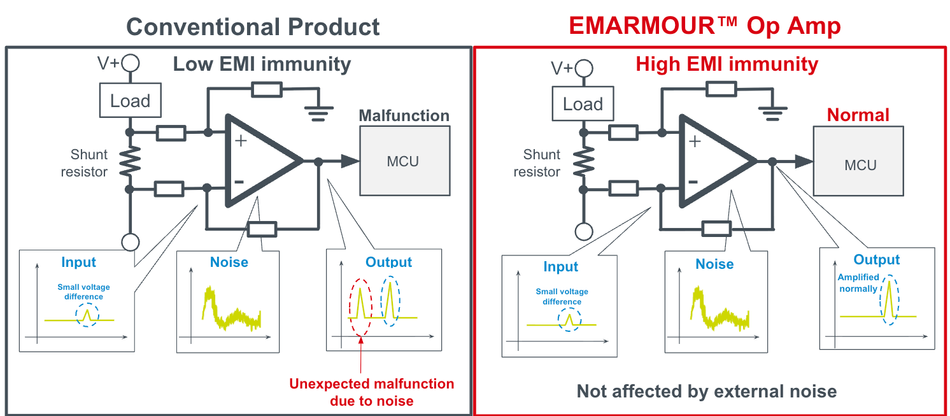

In environments with frequent switching, such as inverters, converters, or automotive ECUs, external interference can distort signals and cause false overcurrent detections. These spurious triggers may interrupt normal operation, reduce efficiency, or, in the worst case, compromise system safety. For engineers, ensuring clean and stable signals is a necessity for dependable control and protection.

Designing for noise resilience requires careful amplifier selection and circuit design. High-EMI immunity devices significantly reduce vulnerability to external disturbances, while architectures that support filtering without accuracy loss help preserve signal integrity. By prioritizing noise immunity, engineers can simplify downstream processing, stabilize microcontroller inputs, and ensure redundant or fail-safe systems function as intended.

ROHM’s Solutions for Building Reliable and Robust Sensing Circuits

ROHM provides a set of components that address the key design challenges in current sensing. Each product family reinforces a different part of the circuit, whether it’s the resistor, the amplifier, or the system’s resilience to noise.

PSR Series Shunt Resistors

The ROHM’s PSR Series represents ROHM’s answer to the reliability issues often encountered with conventional resistors. Built using a metal plate structure, these resistors offer superior thermal cycle resistance and are naturally resistant to sulfurization.

This makes them particularly well-suited for long-term automotive use, where vibration, exhaust gases, and high temperatures can degrade standard thick-film resistors. Their stable characteristics help ensure that the “foundation” of current sensing remains accurate throughout the product’s life.

EMARMOUR™ Operational Amplifiers

The EMARMOUR™ series is ROHM’s dedicated line of Op Amps engineered for ultra-high noise immunity across a wide frequency range. Built using proprietary layout, process, and circuit techniques, these amplifiers maintain signal accuracy without external filtering and meet international EMI standards including ISO 11452-2 and IEC 62132-4. Output variation is minimal even under direct RF injection, significantly reducing the need for peripheral countermeasures. Configurable gain and filtering options offer flexibility, while high immunity ensures stable operation in noise-sensitive automotive and industrial systems.

ROHM Current Sense Amplifiers

When compactness and precision are top priorities, ROHM’s CSAs simplify circuit design by integrating precision gain resistors and employing chopping amplifier architectures. This reduces external component count, minimizes layout errors, and maintains accuracy even when input filtering is required. With a wide input voltage range and strong linearity, these CSAs are ideal for applications like battery management systems, motor drives, and power supplies where space is limited but precision cannot be compromised.

Precision Starts with Smart Design

High-precision current sensing depends on careful choices at each stage of circuit design. The sensing method, shunt resistor, amplifier, and noise handling all contribute to long-term performance and safety. Missing even one can compromise the entire system.

“Reliability isn’t a spec, it’s the sum of every smart design choice you make.”

ROHM helps engineers go beyond component selection with a full lineup of resistors, amplifiers, and current sense ICs, backed by technical resources and design support. Whether you’re starting from scratch or optimizing an existing layout, ROHM helps turn guesswork into certainty.

Learn about ROHM’s EMC countermeasures: Stories of Manufacturing #05 Endless struggle against invisible noise

Explore their portfolio and design tools at rohm.com