Designing High Voltage Contactors (HVC) for Electric Vehicles and Renewable Energy Systems: Key Considerations

This article outlines the key considerations for HVC design in these applications and emphasizes the importance of robust switching solutions in meeting modern industry standards.

As the demand for high-voltage DC applications grows, particularly in electric vehicles (EVs) and renewable energy systems, designing reliable and high-performance high-voltage contactors (HVC) has become a pivotal engineering challenge. Transitioning to high-power, high-density DC energy systems imposes specific design requirements that focus on performance, reliability, and safety under extreme operational conditions. This article outlines the key considerations for HVC design in these applications and emphasizes the importance of robust switching solutions in meeting modern industry standards[1][2].

The Critical Role of High Voltage Contactors in EVs and Renewable Energy

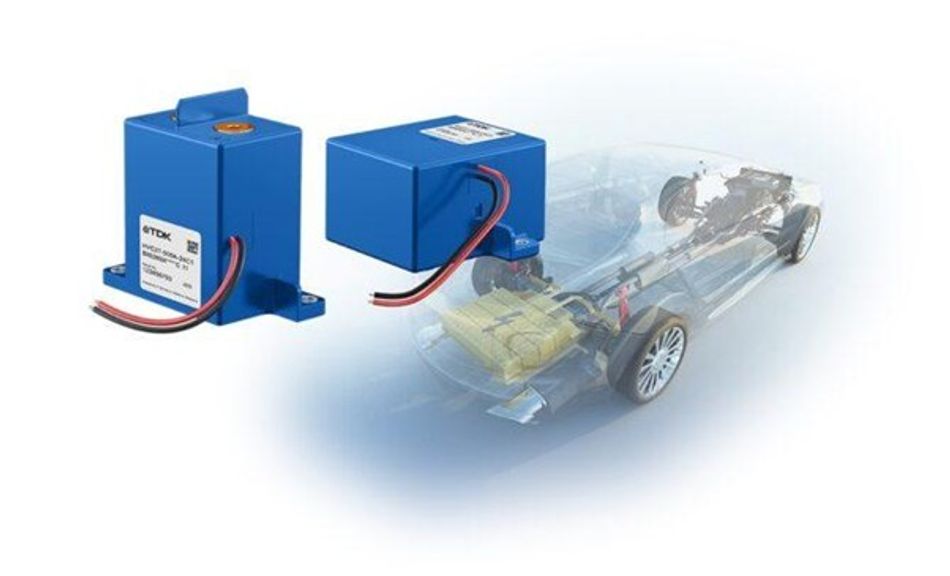

High-voltage contactors are crucial in EVs and renewable energy systems, providing safe and efficient switching under high power loads. In EVs, HVCs play a vital role in the battery management system (BMS), ensuring batteries are disconnected during fault conditions to prevent potential hazards. Similarly, in renewable energy storage systems, reliable switching is essential for maintaining stability and safety during load changes and energy redistribution.

High-power devices, such as those used in EVs and renewable energy systems, must meet stringent requirements for reliability and longevity. The unique demands of DC systems, coupled with the challenges associated with high-voltage applications, requires contactors that can handle these stresses while minimizing wear and extending service life[3][4][5].

Understanding the Basics of DC Switching and Arcing

In DC applications, whenever a high-power device, such as a motor or energy storage system, is turned off under load, the switch, relay, or contactor goes from a closed to an open state. This action initiates an electrical arc, known as a "break arc," between the switch's contact points. Unlike AC systems, where the natural zero-crossing of current and voltage helps extinguish arcs, DC circuits lack this feature. As a result, extraordinary measures must be applied to bring the current to zero and suppress the arc.

The break arc is a high-energy event, often reaching temperatures over 5000 K, which can melt and degrade metallic contact materials. This material can then deposit onto surrounding areas, accelerating contact degradation, and the evaporated metal vapor reduces insulation, shortening the overall service life of the contactor. This long-term cycling process increases contact resistance, resulting in more severe energy handling by the contactors. Effective arc suppression is crucial for reliable high-voltage DC switching, particularly in applications where frequent operation under load is anticipated[4][6].

Reliability Testing for High Voltage Contactors

Why Reliability Testing is Critical

High-voltage contactors operate under extreme conditions, subjecting them to significant thermal, electrical, and mechanical stress. Rigorous testing is required to ensure contactors can withstand these harsh environments commonly found in EVs and renewable energy systems.

Key Testing Parameters

Reliability testing focuses on several critical areas:

- High Power Break [1] Testing: Assesses the contactor's ability to handle the high temperatures and pressures generated by break arcs.

- Electrical Testing: Evaluates performance under varying loads, simulating real-world electrical stresses including high short-circuit current performance.

- Mechanical Testing: Verifies durability, particularly under frequent cycle conditions.

- Environmental Testing: Ensures components can operate reliably in adverse environmental conditions, such as extreme temperatures and high humidity.

Certifications and Standards

Industry certifications, such as UL, and regulations like IEC and ISO serve as benchmarks for safety and reliability. Compliance with these standards ensures that contactors can operate safely and efficiently in high-power applications, making them essential reference points for engineers designing HVC systems[7][8][9].

Addressing Market Trends: High Voltage in EVs and Renewable Energy Systems

The Shift Toward High Voltage Systems

As EVs and renewable energy applications evolve, the demand for high-voltage systems has increased. The need for power-dense, high-voltage components capable of handling larger energy loads without failure is more pressing than ever. High-capacity traction battery batteries (lithium-ion or other kinds of technology), now competitive with internal combustion engines, have mainly driven this demand. Additionally, high-power systems, such as data centers, are pushing the shift toward higher voltage systems—from 400V to 800V and beyond—which enables substantial savings in copper material costs for cables[10].

Moreover, advancements in Solid State Transformer (SST) technologies offer smaller, more efficient transformers that provide isolation. This breakthrough creates new opportunities for robust high-voltage DC contactors, supporting their critical role in EVs and renewable energy applications. However, these batteries require sophisticated BMSs for maximum efficiency and reliable safety due to the potential failure modes, such as over-temperature or short circuit due to external impacts[11][12].

Component Selection for High Voltage Applications

Today’s high-voltage contactors are designed to meet rigorous performance standards prioritizing safety, while balancing the constraints of size, weight, and cost. Innovations in materials and power electronics and advancements in switching technology continue to shape the HVC landscape. The introduction of gas-filled contactors, which provide superior arc suppression capabilities, has significantly enhanced safety and performance in high-stress applications [13].

The Role of Contactors in Ensuring Safety and Performance

The Functionality of High Voltage Contactors

Contactors are vital in connecting and disconnecting high-voltage circuits in EVs and renewable energy systems. In these applications, they act as safety devices, providing galvanic separation and protecting the system from malfunction or overloads.

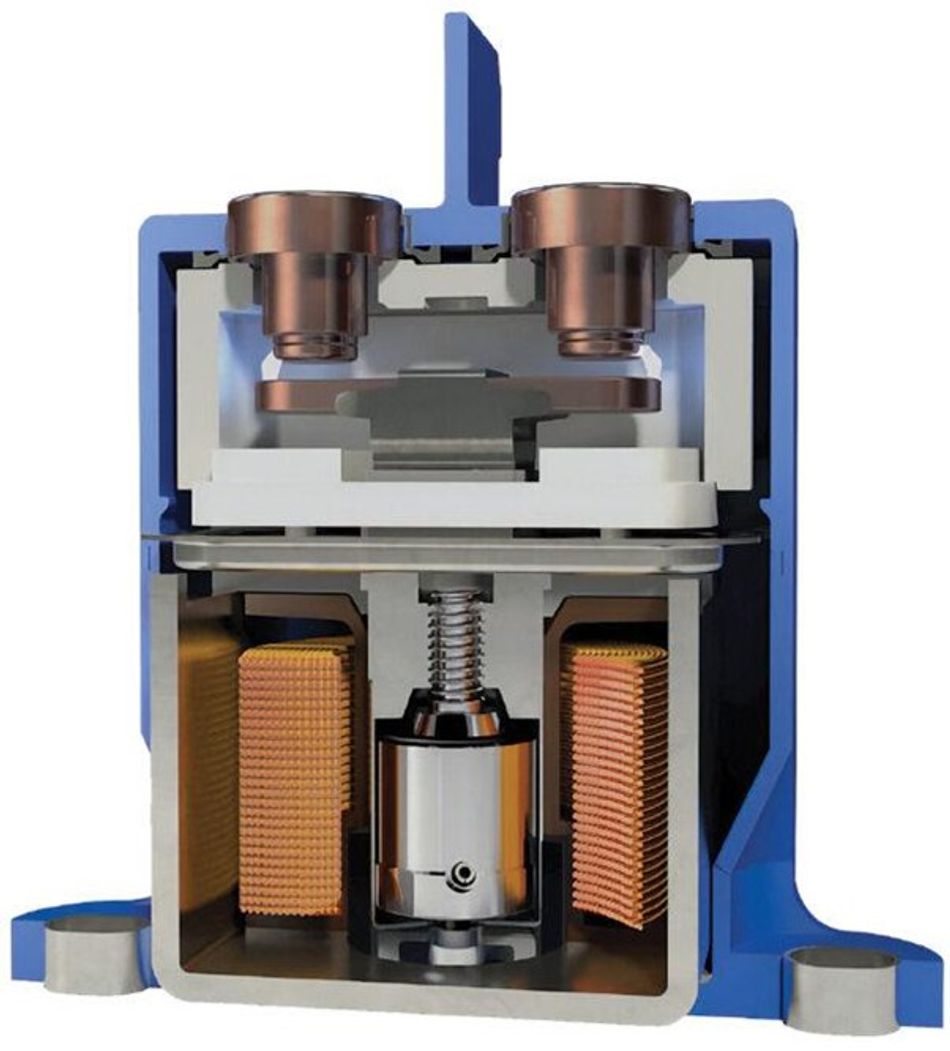

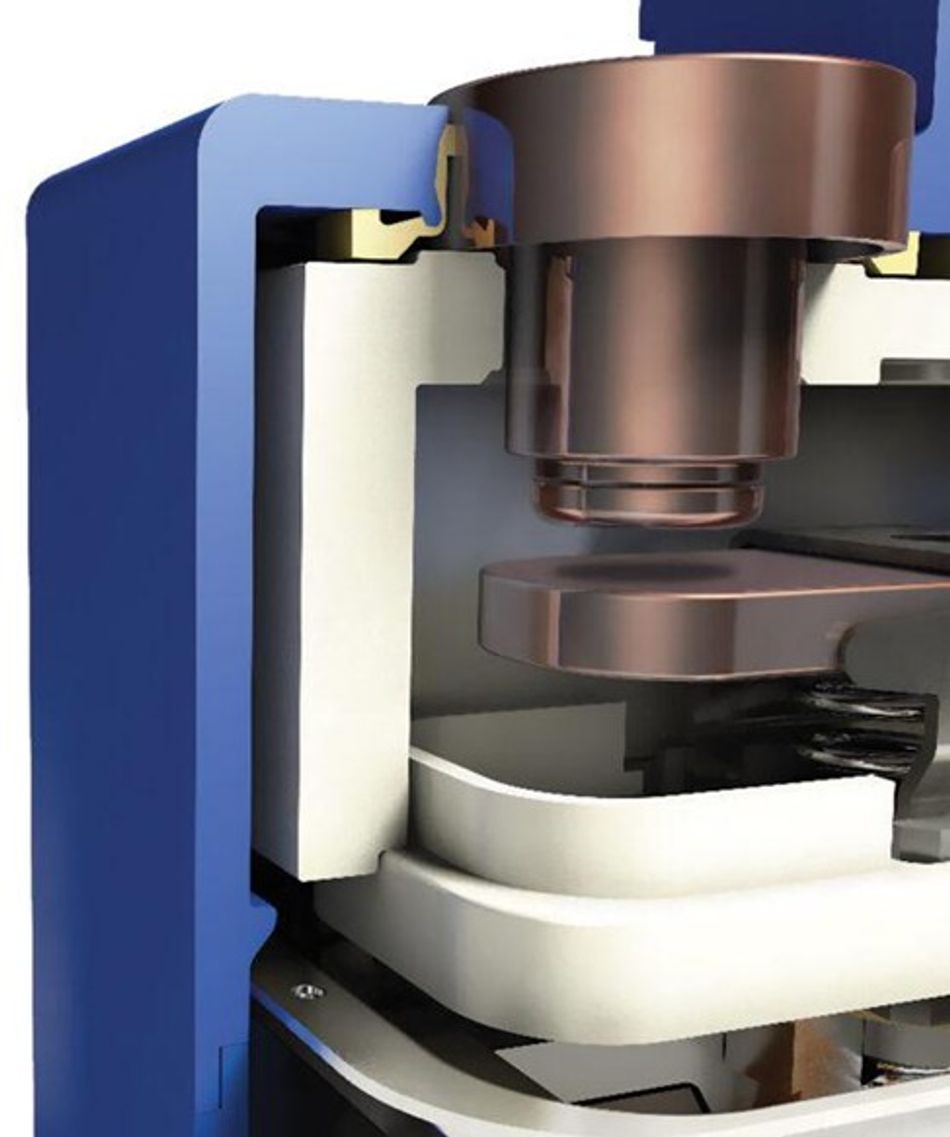

Technologies in Use: Open vs. Gas-Filled Contactors

High-voltage contactors come in two main types:

- Open Contactors: Widely used in general applications but may lack robustness[6] for high-stress environments.

- Gas-Filled Contactors: These contactors suppress arcing by using a gas-filled chamber. By limiting the destructive effects of arcing, gas-filled contactors reduce wear and enable safer, faster disconnections, especially under high loads.

The faster the arc is extinguished, the less heat is generated on the contact terminals of the contactors. This, in turn, means that those contacts are less likely to stick. Gas-filled contactors are particularly beneficial in applications that require frequent operations under load, thereby increasing reliability and extending the component's service life [13][14].

Procurement Considerations for High Voltage Contactors

Selecting the Right Contactor

When choosing high-voltage contactors for EVs and renewable energy applications, several considerations come into play [15]:

- Reliability and Durability: Contactors must consistently perform over long periods without degradation, even in challenging environments.

- Robustness and Safety Ratings: High safety ratings and robustness to electrical, thermal, and environmental stresses are essential.

- Operational Speed: Rapid response times are crucial for ensuring safe circuit disconnections, particularly in emergency situations.

Ensuring Fast and Safe Disconnections Under Load

High-voltage systems inherently present substantial safety challenges, and contactors must operate effectively to mitigate potential hazards. The ability to quickly disconnect high-voltage circuits under load is especially critical in EV charging stations and renewable energy storage systems, where power densities are high. Properly designed contactors with arc-suppressing technologies prevent thermal, mechanical, and electrical damage, preserving the lifespan of the system and enhancing overall safety[16].

Conclusion

Designing high-voltage contactors for electric vehicles and renewable energy systems necessitates careful consideration of performance, reliability, and safety. From understanding the destructive nature of break arcs in DC switching to selecting the appropriate gas-filled or normal contactors based on application needs, engineers must consider each factor’s impact on system integrity. As the market for EVs and renewable energy solutions expands, so will the demand for high-voltage components that can withstand the stresses of these advanced applications. Designers can ensure safe and efficient operation in an evolving energy landscape by selecting reliable, high-performance contactors.

References:

1. High Voltage DC Contactor for New Energy Market - PW Consulting Chemical & Energy Research Center

2. High-Voltage Contactors Application Note

3. Driving High-Voltage Contactors in EV and HEVs (Rev. A)

4. High-current, high-voltage DC switching White Paper

5. Applications of DC Contactors in Energy Storage Systems - HIITIO

6. White Paper | Challenges in switching DC voltages - Schaltbau

7. What Are UL Standards: A Focus on DC Electrical Components - DC Electrical Components Manufacturer

8. Global Certifications for HVDC Contactor - HIITIO

9. Type Test Items for Contactors According to IEC Standards - BTB Electric

10. Power Architecture Evolution in Data Centers

11. The Solid-State Shift: Reinventing the Transformer for Modern Grids

13. Gas-Filled Contactors Defeat High-Voltage, High-Current Switching Woes | Electronic Design

14. te-connectivity-gas-filling-in-dc-contactors-hydrogen-vs-nitrogen.pdf

16. High-voltage contactor enables safer power switching for EVs - EV Engineering & Infrastructure