Design Without Silos: Bridging Electrical and Mechanical

The Invisible Wall Between Disciplines

Every engineer has been there—the meeting where mechanical and electrical teams finally bring their designs together, only to realize they don’t fit. The PCB extends a few millimeters too far into the enclosure. The connector conflicts with a mounting post. The cooling vents don’t align with the components that need them most.

It’s not because anyone did their job poorly—it’s because they did it separately. For decades, electrical and mechanical engineers have worked side by side but not together, relying on file exchanges, late reviews, and design assumptions. What starts as collaboration often turns into a series of disconnected efforts stitched together at the end. What it should be is co-creation.

In an era where every product—from wearables to EVs—demands tighter integration between form and function, those old boundaries are showing their cracks. PCB designs are also becoming more complex, packing more functionality into tighter spaces than ever before. The results are costly: more re-spins, longer timelines, and less time spent actually designing.

When Misalignment Becomes Expensive

The price of misalignment isn’t just financial—it’s emotional. Teams lose confidence when the same problem repeats across projects. Engineers find themselves firefighting instead of innovating, spending days resolving conflicts that could have been caught in hours. In fact, a Forrester study found that each designer can save up to 159 hours in the first year thanks to streamlined processes.

A single enclosure mismatch can delay a launch by weeks. A missed component height can trigger an entire board redesign. Multiply that by multiple projects, distributed teams, and the pressure to deliver faster than ever—and the gap between ECAD and MCAD becomes a liability no team can afford.

And while older engineers might be accustomed to these struggles as “character-building”, younger ones are less forgiving. They’ve grown up with real-time collaboration tools everywhere else—why should hardware design still run on file transfers and emails?

Why Traditional Collaboration Falls Short

“Collaboration” between ECAD and MCAD has too often meant exchanging STEP files over email and hoping the versions line up. Each side works in its own domain, using its own language, and the fundamental formats are not directly compatible. The only time the full picture emerges is at the end—when change is expensive.

In practice, this creates the expectation of friction:

Outdated geometry files lead to design clashes.

Manual version tracking wastes time.

Visual alignment checks become guesswork instead of verification.

Manual data translation is time-consuming and error-prone.

It’s not that engineers don’t collaborate—it’s that their tools make it harder than it should be. The traditional handoff model assumes design moves in neat, predictable stages. Modern product development doesn’t work that way. Today’s hardware often involves multiboard systems, flexible circuits, and compact enclosures like wearables—making alignment between electrical and mechanical design more critical than ever. The complexity has evolved, but the tools haven’t kept up.

Shared Context = Shared Speed

The real solution isn’t more meetings—it’s more context. When mechanical and electrical engineers share a synchronized design view, collaboration becomes a natural part of the process instead of a scheduled checkpoint.

Real-time ECAD–MCAD synchronization means:

PCB outlines, components, and enclosures stay synchronized in real-time as both sides make changes.

Engineers can catch fit, clearance, and placement issues before fabrication.

Mechanical and electrical teams can review designs in the same environment, reducing miscommunication and accelerating iteration.

When everyone can see the same thing at the same time, decisions happen faster. Engineers stop working around each other and start working with each other.

How Altium Develop Bridges the Gap

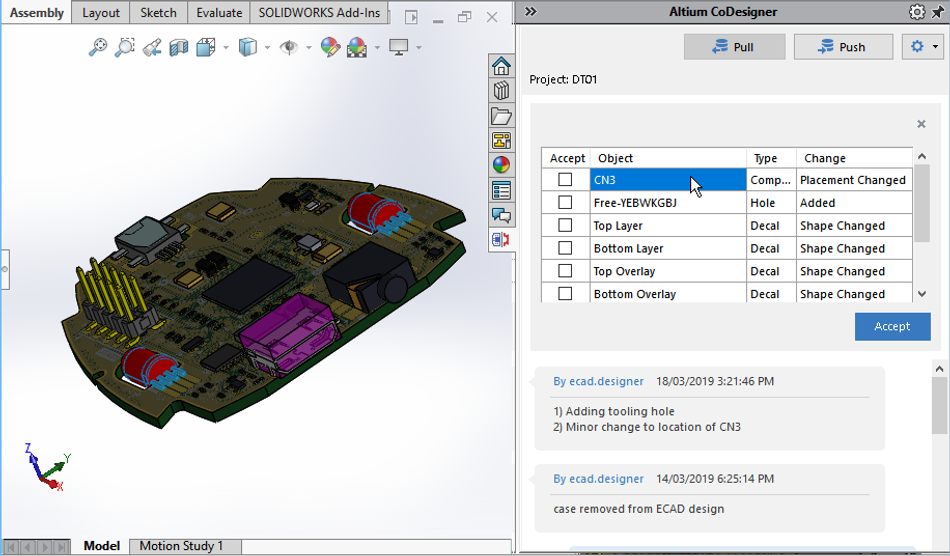

This is exactly what Altium Develop was built to enable—electrical and mechanical design in real time, within one shared environment.

Instead of exchanging files, ECAD and MCAD engineers can co-create using synchronized data. Changes update instantly across their preferred design tools. Mechanical feedback can be given directly in the design view. Electrical designers can visualize mechanical constraints while they do their work.

Altium Develop comes with capabilities like:

Real-time, bi-directional ECAD–MCAD synchronization for continuous alignment and seamless data exchange

Shared context that eliminates version confusion

Advanced traceability that records all design changes, comments, and decisions across domains.

Flexible and free collaboration access for mechanical stakeholders.

Altium Develop transforms cross-domain collaboration from reactive coordination into true co-creation.

A New Way to Build Together

Engineering should be about solving problems, not managing CAD data translation. The next generation of hardware professionals doesn’t want to waste their creativity on logistics—they want seamless workflows that let them move fast, make informed decisions, and build confidently.

Breaking down the walls between electrical and mechanical design isn’t just about efficiency gains—it’s a cultural shift. It restores what collaboration was always meant to be: shared ownership, shared understanding, and shared progress.

When ECAD and MCAD teams design without silos, innovation stops waiting for alignment meetings. It happens continuously, as ideas evolve—together. That’s the future Altium Develop enables—where electrical and mechanical engineers co-create, not coordinate.