Closing the Gap: The Rise of Accessible Post-Processing Solutions for Industrial 3D Printing

Additive manufacturing is moving into large-scale production, but post-processing remains a key hurdle. Explore how emerging automation solutions are addressing key challenges at Formnext 2025.

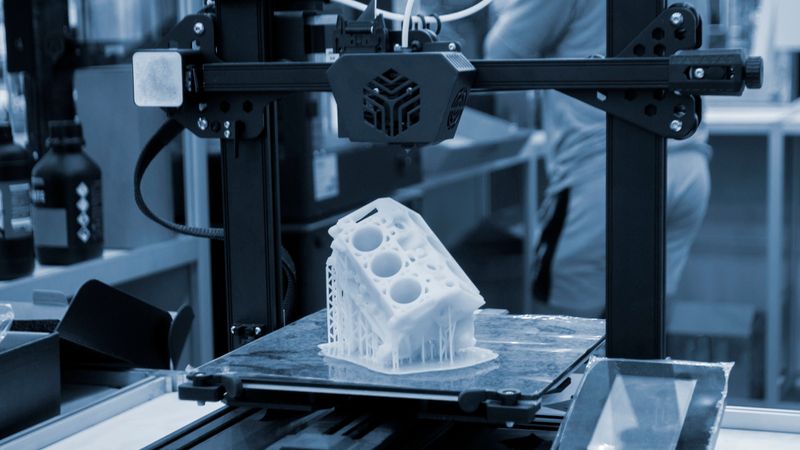

Additive manufacturing (AM) was once synonymous with prototyping and experimental design. However, Its scope is broadening to include scaled and high-volume production applications. The 3D printing sector has experienced swift expansion, with its market size rising from $20.68 billion in 2023 to an estimated $24.61 billion in 2024. This upward trend is anticipated to continue, with forecasts suggesting the market could hit approximately $117.78 billion by 2033, reflecting a compound annual growth rate (CAGR) of 19% over the 2024–2033 period. 1

As companies integrate 3D printing into full-scale manufacturing, they’re discovering not just its design flexibility and speed but also its logistical and economic potential. However, unlike traditional manufacturing methods, where finishing is often well-optimized and automated, AM still faces a complex and often manual post-processing stage. As companies look to scale their 3D printing capabilities, the bottleneck created by inefficient post-processing becomes more prominent.

New post-processing solutions are being designed with accessibility, scalability, and automation in mind to tackle this bottleneck. This article discusses how new solutions are making AM more viable for industrial use and how Formnext 2025 presents a key venue where these innovations and solutions are explored and showcased.

The Needs of Post-Processing in High-Volume Production

The role of post-processing is increasing in manufacturing setup as companies move from small-batch prototyping to full-scale AM. In prototyping environments, manual or semi-manual methods involving basic sanding, support removal, or superficial cleaning may suffice. However, these methods become inefficient, inconsistent, and labor-intensive when applied to higher volumes.

At an industrial scale, post-processing must handle significantly larger quantities and meet tighter tolerances and surface finish requirements. Production environments demand faster turnaround times, uniform results, and the ability to meet industry-specific compliance standards. This makes post-processing a critical step that determines the feasibility and profitability of using AM at scale.

Moreover, in high-volume production, core steps such as support removal, depowdering (for powder-bed fusion processes), surface smoothing, chemical or thermal curing, and cleaning become more complex. Each step introduces potential points of variability that can affect final part performance and aesthetic quality, especially when done manually. Therefore, scalable solutions must ensure that each step is tightly controlled and repeatable. In this regard, automation is increasingly employed in post-processing. Automated systems accelerate operations and minimize human error and physical strain on operators. Incorporating automated systems into post-processing workflows improves both speed and repeatability as well.

In production settings, defects or surface deviations can result in rejected parts, rework, or failure in end-use applications. Therefore, robust quality control mechanisms must be integrated directly into the post-processing workflow. This includes features such as in-line inspection, real-time feedback systems, and traceable process parameters that ensure repeatability from part to part.

Innovations in Post-Processing Technologies

The latest innovations are focused on automating repetitive tasks and enhancing process control. New-generation post-processing systems are incorporating robotics, AI, and closed-loop feedback to reduce manual intervention. For instance, intelligent part recognition systems can identify part geometries and automatically select appropriate finishing parameters. Adaptive surface treatment technologies where equipment can fine-tune blasting intensity or polishing profiles in real-time based on sensor feedback are also emerging.

In hybrid manufacturing environments, 3D printing operates alongside traditional CNC machining or injection molding. For instance, modular post-processing units can be integrated into multi-step production cells, allowing components to transition automatically from 3D printing to machining to finishing without manual handling, enabling fully hybrid production lines. Advanced post-processing solutions are designed with software and hardware integration in mind for such hybrid systems. Such systems can receive print-job metadata directly from the printer and adjust their processing parameters accordingly to ensure optimal settings for different materials, geometries, and finishes.

Another area of rapid development is materials handling, particularly in powder-based AM processes such as Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). Here, dust control and automated powder removal systems are playing an important role in maintaining both part quality and workplace safety.

Bridging the Gap Between Prototyping and Production

Transitioning from prototype to serial production is challenging for manufacturers. However, modern solutions are facilitating this transition. Manufacturers moving from prototyping to production benefit from technologies that simplify the scaling process. These solutions often include automation in post-processing steps such as support removal, surface finishing, and quality inspection. Automation reduces manual intervention and variability, enabling manufacturers to maintain consistent quality across larger production volumes.

Adjusting workflows through automation and integration leads to several advantages. For instance, enhanced throughput means parts move more quickly from printing through post-processing to final inspection, which accelerates overall production timelines. Moreover, reducing manual labor lowers operational costs and allows skilled workers to focus on higher-value tasks, which is crucial for scaling production economically. These improvements collectively support the transition from producing individual custom parts to efficient serial manufacturing.

Similarly, comprehensive software ecosystems are central to bridging the gap between prototyping and production. These platforms enable real-time data sharing between CAD tools, slicing software, and post-processing equipment, creating a connected workflow that reduces errors and speeds up decision-making. Moreover, traceability features allow teams to track each part’s journey from design to delivery, which is critical for quality assurance in regulated industries. Advanced scheduling algorithms can also optimize job queues based on machine availability and part priority, enhancing overall productivity.

The Role of Formnext in Post-Processing Advancements

Formnext is the leading exhibition for AM and industrial 3D printing and has become central to the advancement of post-processing solutions. The event brings together equipment manufacturers, software developers, and users to demonstrate how integrated solutions connect design and production in a smoother workflow. Many breakthrough post-processing systems are either introduced or iterated upon at Formnext.

Case Studies and Industrial Examples

Several companies at previous Formnext events have demonstrated how advanced post-processing technologies are reshaping industrial 3D printing. For instance, at the 2024 Formnext event, Solukon presented its SFM-AT350 system, which automates the removal of powder from complex metal parts using programmable rotation and targeted vibration. This innovation addresses the challenge of cleaning intricate geometries, significantly reducing manual labor and ensuring a higher level of process consistency. Solukon’s technology allows manufacturers to handle larger production volumes with greater reliability and less operator intervention by automating this critical post-processing step.

Joke Technology’s Eneskapostprocess 5.0 workstation was also part of the Formnext exhibition 2024. This upgraded system features a 50% increase in workspace volume of up to 560 liters and supports components weighing up to 250 kilograms. Despite the expanded capacity, the unit is compact and ergonomic, with options for manual, forklift, or crane loading. This solution enables manufacturers to scale up part sizes without compromising on safe and efficient post-processing workflows.

AMbitious powered by Toolcraft introduced a dry ice blasting system at Formnext 2024. It is designed to remove support structures from metal AM parts. Traditionally a labor-intensive task, support removal is now semi-automated, cutting throughput times by up to 15 minutes per component. In addition to increasing productivity, the technology reduces physical strain on operators, providing a dual improvement in operational efficiency and workplace ergonomics. Toolcraft AG is already applying this method in production.

Similarly, Xioneer addresses post-processing for granulate and filament-based 3D printing with its VXL 150 soluble support material and Vortex XL dissolving tank. The new system, available in three versions, nearly doubles the capacity to 60 liters, catering to high-temperature printing needs. For dental and smaller-scale applications, Xioneer’s Vortex EZ Dental desktop station offers quick, heat-assisted support material removal.

These examples exhibited at Formnext 2024 show us how accessible and targeted post-processing innovations are enhancing scalability, repeatability, and ease of use.

Conclusion

Advanced post-processing solutions enable manufacturers to scale production with improved quality, reduced costs, and greater consistency by automating and optimizing critical post-printing steps.

In this regard, continued innovation and collaboration across the AM ecosystem are essential. Formnext 2025 will be a premier venue to witness firsthand the latest breakthroughs in post-processing technologies and their integration into end-to-end manufacturing workflows. Formnexts AM Directory will show you which exhibitors will showcase 2025 postprocessing solutions.

Register for the Formnext newsletter to stay informed on these exciting developments and industry trends. This will provide ongoing updates and insights into how accessible post-processing solutions are shaping the future of industrial 3D printing, or secure your Formnext ticket directly. Until 21 October they will grant a early bird price in the ticket shop.

References

3D Printing Market Size, Share, and Trends 2024 to 2033. [Online] Precedence Research. Available at: https://www.precedenceresearch.com/3d-printing-market (Accessed on May 8, 2024)

Formnext – the industry hub for Additive Manufacturing [Online] Formnext. Available at: https://formnext.mesago.com/frankfurt/en.html (Accessed on May 8, 2025)

Highlights and premieres for Formnext 2024: Ancillary process systems. [Online] Formnext. Available at: https://formnext.mesago.com/frankfurt/en/industry-insights/fonmag/fonmag_articles/articles/a-wide-range-of-impressive-innovations-in-post-processing.html (Accessed on May 8, 2025)