Carbon Fiber 3D Printing: Revolutionizing Additive Manufacturing

Carbon fiber 3D printing represents a significant advancement in additive manufacturing technology, combining the strength and lightweight properties of carbon fiber with the design flexibility of 3D printing.

This article was first published on

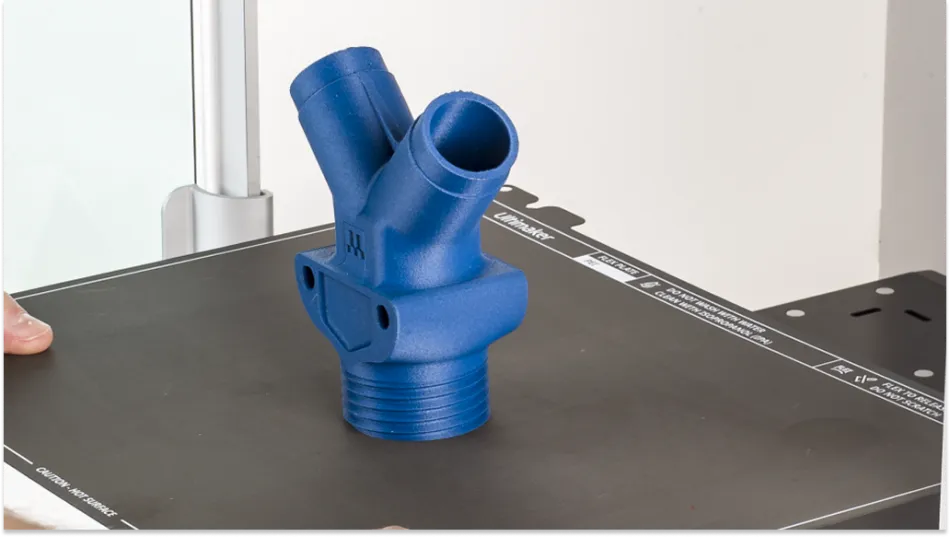

ultimaker.comIntroduction to carbon fiber 3D printing

This innovative process involves incorporating carbon fibers into traditional 3D printing materials to create parts with enhanced mechanical properties.

There are two main approaches to carbon fiber 3D printing:

- Chopped fiber filaments: Short carbon fiber strands are mixed into thermoplastic filaments like PLA, ABS, or nylon. These filaments can be used with modified FDM (Fused Deposition Modeling) printers.

- Continuous fiber printing: Long, continuous strands of carbon fiber are laid down alongside thermoplastic material during the printing process. This method requires specialized printers designed for 3D composite printing.

The addition of carbon fibers to 3D printing materials offers several key benefits:

- Increased strength and stiffness compared to standard thermoplastics

- Improved dimensional stability and reduced warping

- Higher heat resistance

- Lightweight yet durable parts

These properties make carbon fiber 3D printing particularly valuable for industries like aerospace, automotive, and high-performance sports equipment manufacturing.

The technology enables the production of complex geometries with excellent strength-to-weight ratios that would be difficult or impossible to achieve with traditional manufacturing methods.

However, successfully implementing carbon fiber 3D printing requires specialized equipment and expertise. The abrasive nature of carbon fibers necessitates the use of hardened steel nozzles and robust extrusion systems.

Additionally, optimizing print parameters and design strategies is crucial to fully leverage the material's unique properties.

As 3D composite printing technology continues to advance, we can expect to see broader adoption across various industries, opening up new possibilities for lightweight, high-strength parts and pushing the boundaries of what's possible in additive manufacturing.

Learn more about the advantages of 3D printing with carbon fiber to understand how this technology is transforming various industries.

3D printers that print carbon fiber - capabilities and features

Building on the introduction to carbon fiber 3D printing, let's explore the specialized printers capable of working with these advanced materials.

3D printers that print carbon fiber offer enhanced capabilities compared to standard 3D printers, allowing for the production of stronger, lighter, and more durable parts. These specialized printers typically fall into two main categories:

- Printers that use chopped carbon fiber filaments

- Printers designed for continuous fiber 3D printing

Chopped carbon fiber printers use filaments where short carbon fiber strands are mixed into thermoplastics like PLA, ABS, or nylon. These printers require:

- Hardened steel nozzles to resist abrasion from the carbon fibers

- Higher extrusion temperatures, often up to 300°C

- Robust extruder systems to handle the more brittle carbon fiber filaments

Continuous fiber 3D printing systems are more specialized, featuring:

- Dual extrusion systems - one for the thermoplastic matrix and one for laying down continuous carbon fiber

- Cutting mechanisms to trim the continuous fiber between layers

- Software to optimize fiber placement for maximum part strength

Key capabilities of carbon fiber 3D printers include:

- Producing parts with higher strength-to-weight ratios than standard 3D printed plastics

- Improved dimensional stability and reduced warping of printed parts

- The ability to create functional prototypes and end-use parts for demanding applications

- Printing with a variety of carbon fiber-reinforced materials beyond just PLA, including nylon, PETG, and high-performance polymers like PEEK

When selecting a 3D printer that prints carbon fiber, important features to consider are:

- Build volume - larger sizes allow for bigger parts

- Print speed and acceleration capabilities

- Heated build chambers for high-temperature materials

- Automatic bed leveling systems

- Filament monitoring and management systems

- Compatibility with a range of carbon fiber composite materials

While 3D printers that print carbon fiber offer significant advantages, they also come with some challenges:

- Higher initial costs compared to standard 3D printers

- More complex printing processes requiring careful parameter tuning

- Increased maintenance due to the abrasive nature of carbon fibers

- Potential health and safety concerns when handling carbon fiber materials

Despite these challenges, the ability to produce high-strength, lightweight parts makes carbon fiber 3D printing an increasingly valuable technology across industries like aerospace, automotive, and high-performance sports equipment manufacturing.

Carbon fibre 3D printer filament - types and properties

Now that we've explored the capabilities of carbon fiber 3D printers, let's delve into the various types of filaments used in this advanced manufacturing process. Carbon fibre 3D printer filament comes in several types, each with unique properties that make them suitable for different applications:

Chopped carbon fiber filaments

These filaments contain short carbon fiber strands mixed into thermoplastic materials:

- Carbon fiber PLA filament: Offers improved stiffness and dimensional stability compared to standard PLA, with a matte black finish that hides layer lines.

- ABS carbon fiber: Provides enhanced strength and heat resistance over regular ABS, making it suitable for functional prototypes and end-use parts.

- Carbon fiber-reinforced PETG: Combines PETG's ease of printing with increased stiffness and reduced warping from the carbon fibers.

- Carbon fiber nylon: Offers exceptional strength, stiffness, and chemical resistance, ideal for industrial applications.

Continuous carbon fiber filaments

These specialized filaments lay down continuous strands of carbon fiber alongside a thermoplastic matrix:

- Nylon-based continuous carbon fiber: Provides metal-like strength in printed parts, suitable for replacing aluminum components.

- PEEK with continuous carbon fiber: Offers extremely high strength and heat resistance for aerospace and medical applications.

Key properties of carbon fiber filaments

Compared to standard 3D printing materials, carbon fibre 3D printer filaments typically offer:

- Higher tensile strength and stiffness

- Improved dimensional stability and reduced warping

- Better heat resistance

- Lightweight yet durable parts

- Increased abrasion resistance

However, carbon fiber filaments also have some challenges:

- Require hardened steel nozzles to prevent wear

- Can be more brittle than non-filled filaments

- Often need higher printing temperatures

- More expensive than standard filaments

When selecting a carbon fibre 3D printer filament, consider the specific mechanical properties required for your application, as well as the compatibility with your 3D printer's capabilities.

Proper printer settings and handling are crucial to achieve optimal results with these advanced materials. For a comprehensive understanding of carbon fiber 3D printing materials and their applications, check out this free guide to 3D printing carbon fiber.

Best practices for printing carbon fiber

With an understanding of carbon fiber filaments and their properties, it's essential to follow best practices to achieve optimal results. To successfully print carbon fiber filaments, there are several key best practices to follow:

Use a hardened steel nozzle

Carbon fiber filaments are highly abrasive and will quickly wear out standard brass nozzles. A hardened steel nozzle is essential for printing these materials without damaging your printer. Some high-end printers come with hardened nozzles specifically designed for abrasive filaments.

Adjust print temperature

Carbon fiber filled filaments often require higher print temperatures than their unfilled counterparts. Experiment with temperatures 20-40°C higher than you would use for the base material to ensure proper layer adhesion and flow.

Reduce print speed

Printing at a slower speed, around 30-50 mm/s, can help improve print quality and reduce the chances of clogging when using carbon fiber filaments. This allows more time for the material to properly melt and flow.

Use a direct drive extruder

Carbon fiber filaments tend to be more brittle than standard materials. A direct drive extruder provides better control and reduces the distance the filament must travel, lowering the risk of breakage.

Increase extrusion multiplier

Carbon fiber filaments may require a slightly higher extrusion multiplier (around 1.05-1.10) to ensure proper layer adhesion and fill density.

Choose the right carbon fiber filament

Not all carbon fiber filaments are created equal. Look for high-quality options from reputable manufacturers. The best carbon fiber filament will depend on your specific application, but popular choices include:

- Nylon-based carbon fiber filaments for strength and durability

- PETG-based carbon fiber filaments for easier printing and good layer adhesion

- Polycarbonate-based carbon fiber filaments for high heat resistance

Ensure proper bed adhesion

Use a textured build plate or apply an adhesive solution to ensure the first layer sticks well. Carbon fiber parts can be prone to warping, so good bed adhesion is crucial.

Dry your filament

Many carbon fiber filaments, especially those with a nylon base, are hygroscopic and absorb moisture from the air. Dry your filament before printing to avoid quality issues and potential damage to your printer.

Adjust cooling settings

Carbon fiber filled materials often benefit from reduced cooling. Try lowering your fan speed to around 50% to improve layer adhesion and overall part strength.

By following these best practices, you can successfully print carbon fiber parts with improved strength, stiffness, and dimensional stability compared to standard 3D printing materials. For more detailed insights on working with carbon fiber in 3D printing, including specific applications and case studies, explore this guide on finding the perfect carbon fiber 3D printing application.

Applications of carbon fiber 3D printing

The unique properties of carbon fiber 3D printed parts open up a wide range of applications across various industries. Carbon fiber 3D printing has revolutionized these sectors by enabling the production of strong, lightweight parts with complex geometries. Some key applications include:

Aerospace and automotive

- Lightweight structural components

- Prototypes for aerodynamic testing

- Custom interior parts

- Tooling and fixtures for manufacturing

Sports equipment

- Bicycle frames and components

- Prosthetic limbs for athletes

- Customized protective gear

Industrial tooling

- 3D printed carbon fiber molds for composite part production

- Jigs and fixtures for assembly lines

- End-of-arm tooling for robotics

Medical devices

- Customized prosthetics and orthotics

- Surgical instruments

- Anatomical models for surgical planning

Consumer products

- High-performance drone frames

- Lightweight camera equipment

- Custom electronic enclosures

The versatility of carbon filament in 3D printing allows for rapid prototyping and production of parts with excellent strength-to-weight ratios. This enables manufacturers to:

- Reduce lead times for custom parts

- Iterate designs quickly and cost-effectively

- Produce complex geometries not possible with traditional manufacturing

- Create lightweight parts without compromising strength

Of particular significance is the use of 3D printed carbon fiber molds in composite manufacturing. These molds offer several advantages over traditional tooling:

- Faster production of molds for short-run or prototype parts

- Reduced cost for low-volume production

- Ability to create complex mold geometries

- Lightweight molds that are easier to handle

As carbon filament technology continues to advance, we can expect to see even more innovative applications across various industries, pushing the boundaries of what's possible in additive manufacturing. For those considering whether to use carbon fiber or metal for their 3D printing projects, this comparison of carbon fiber and metal 3D printing provides valuable insights to help make an informed decision.

Challenges and considerations in carbon fiber 3D printing

While carbon fiber 3D printing offers numerous advantages, it's important to be aware of the challenges and considerations involved in this advanced manufacturing process. Carbon fiber 3D printing presents several key challenges and considerations to keep in mind:

Specialized equipment requirements

- Hardened steel nozzles: Carbon fiber filaments are highly abrasive and will quickly wear out standard brass nozzles.

- Direct drive extruders: Recommended for better control and reduced risk of filament breakage.

- Higher temperature capabilities: Many carbon fiber filaments require higher printing temperatures than standard materials.

Printing challenges

- Increased brittleness: Carbon fiber filaments tend to be more brittle than their non-filled counterparts, requiring careful handling.

- Potential for clogging: The abrasive nature of carbon fibers can lead to more frequent nozzle clogs.

- Reduced layer adhesion: Carbon fiber can sometimes interfere with layer bonding, requiring careful parameter tuning.

Material considerations

- Higher cost: Carbon fiber filaments are generally more expensive than standard 3D printing materials.

- Moisture sensitivity: Many carbon fiber-filled materials, especially those with a nylon base, are hygroscopic and require proper storage and drying.

- Limited flexibility: Parts printed with carbon fiber tend to be stiffer and less flexible than those made with unfilled materials.

Post-processing and finishing

- Increased difficulty in sanding and finishing due to the hardness of carbon fibers.

- Potential health hazards from carbon fiber dust during post-processing, requiring proper safety equipment.

Design considerations

When designing parts for carbon fiber 3D printing, it's important to consider:

- Anisotropic properties: Strength may vary depending on print orientation and fiber alignment.

- Wall thickness: Carbon fiber parts may require thicker walls than standard materials for optimal strength.

- Support structures: Careful placement of supports is crucial due to the material's properties.

Environmental and safety concerns

- Proper ventilation is essential when printing with carbon fiber materials to avoid inhaling potentially harmful particles.

- Disposal of carbon fiber waste requires special consideration due to its non-biodegradable nature.

Despite these challenges, many manufacturers find that the benefits of carbon fiber 3D printing outweigh the drawbacks for certain applications. Careful material selection, printer setup, and parameter tuning can help mitigate many of these issues, allowing for the production of high-strength, lightweight parts that were previously difficult or impossible to manufacture.

Future trends in carbon fiber additive manufacturing

As we look ahead, the field of carbon fiber 3D printing continues to evolve rapidly, building on the challenges and applications discussed earlier. Several key trends are emerging that will shape the future of this innovative manufacturing process:

Improved material formulations

- Development of new carbon fiber composites with enhanced mechanical properties

- Integration of nanoparticles to further improve strength and conductivity

- Creation of hybrid materials combining carbon fiber with other high-performance additives

Advancements in printer technology

- Higher precision and resolution in 3D composite printing

- Faster print speeds without sacrificing part quality

- Larger build volumes to accommodate bigger components

- Multi-material printing capabilities for functionally graded parts

Expanded applications

The versatility of carbon fiber 3D printing is opening up new possibilities across various industries:

- Aerospace: Lightweight structural components and interior parts

- Automotive: Custom performance parts and tooling

- Medical: Patient-specific prosthetics and implants

- Sports equipment: Personalized high-performance gear

Sustainability initiatives

As environmental concerns grow, the industry is focusing on:

- Development of recyclable and biodegradable carbon fiber composites

- Improved recycling processes for carbon fiber waste

- Reduction of energy consumption in the manufacturing process

Integration with other technologies

Carbon fiber 3D printing is increasingly being combined with complementary technologies:

- AI and machine learning for optimized part design and print parameters

- In-situ monitoring and quality control systems

- Post-processing automation for improved surface finish and dimensional accuracy

Standardization and certification

To facilitate wider adoption, particularly in regulated industries:

- Development of industry standards for 3D composite printing processes and materials

- Certification programs for carbon fiber 3D printed parts

- Improved testing and validation methods for quality assurance

Cost reduction

Efforts to make carbon fiber 3D printing more accessible include:

- Streamlined production processes for carbon fiber materials

- Development of more affordable printer systems

- Optimization of print parameters to reduce material waste

These trends collectively point towards a future where carbon fiber 3D printing becomes an increasingly integral part of advanced manufacturing, enabling the production of stronger, lighter, and more complex parts across a wide range of industries. As the technology matures, we can expect to see continued innovation and broader adoption, further revolutionizing the field of additive manufacturing.