3D Printing Sustainable Casts

As technology has become more accessible, 3D Printed casts have grown in popularity, owing to several benefits. However, all casts share a fundamental flaw - they are single-use products

Further harnessing 3D printing technology to promote sustainability within the medical industry

Orthopaedic cast immobilisation is one of the most common ways to treat broken and fractured bones. This process involves the use of materials to encase and restrict the movement of broken bones, allowing them to heal.

As technology has become more accessible, 3D Printed casts have grown in popularity. They are much lighter, more comfortable and easier to produce than traditional casts. Despite the evolution in cast production qualities, all casts share a fundamental flaw – they are single-use products.

Since the job of a cast is to set body parts in a fixed position, they have to be tailor-made to the unique anatomy of the individual patients.

3D printed casts are also complex in their structure, these factors eliminate the possibility of reusing casts, even if hygiene issues were non-existent.

CREATE Education Ambassador, Jack Cockle identified an opportunity to explore alternative strategies to make immobilisation casts more sustainable. With an aim to reduce the inevitable waste generated by their complex and tailored form and maintenance of hygiene standards.

The Process

As part of one of Jack’s final year projects whilst studying BA (Hons) Sustainable Product Design, he began by making a normal plaster cast, trialling traditional methods of the cast making to justify future design choices.

Then making a basic 3D printed cast, by scanning his hand/arm using a 3D scanner and software. Exporting the scan as an STL file into Autodesk Fusion 360, which was then converted to a b-rep file, allowing Jack to model a form around the hand/arm.

Next, 3D printing the cast in rPETG on the Ultimaker S5. This was made easier by the scale of the printer, saving time where Jack would have had to split up the model into more pieces, then glueing them together.

To explore the scope of making casts more sustainable, Jack evaluated multiple design ideas through an iterative process. The aim was to investigate the possibility of fabricating 3D printed casts that adapt to the form of the user, rather than existing as a rigid form tailored to individual patients, thus making them more suitable for reuse.

This idea came to Jack as his colleagues tried on the 3D printed cast, which almost, but didn’t perfectly fit them due to the varied shapes of individuals' limbs.

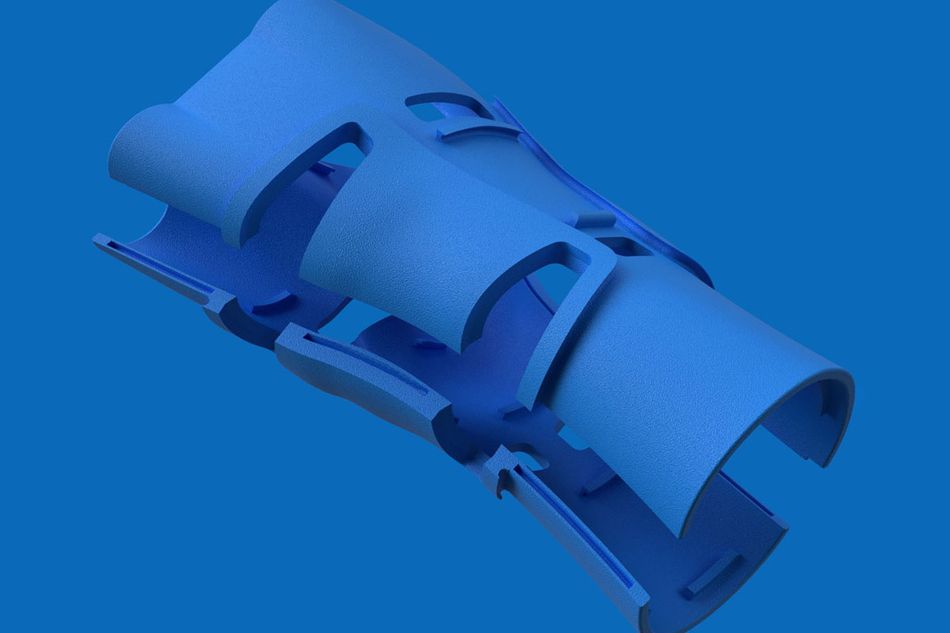

Owing to Auxetic materials and structures exhibiting certain abnormal mechanical responses, thanks to the possession of negative Poisson’s ratio response. Meaning they get thicker when stretched lengthwise and thinner when compressed. Jack began experimenting with auxetic forms in different materials such as TPU and Flexible Resin.

In Rhino3D, Jack generated a series of cylindrical auxetic lattice forms, choosing the ones that required no support material (as this would be difficult to remove from such a complex structure). Jack printed them in both TPU and flexible resin to test how well each structure and material compressed under pressure.

The concept was a flexible resin auxetic sleeve that fits over the arm of the patient, which is compressed by the rigid PETg shell, immobilising the limb.

In theory, the reusable cast would reduce waste, cut lead times (as a stock of casts could be kept) and the longer-term cost of casts per patient (since the costs of one cast could be distributed across several patients).

Jack has been developing the mesh further, to become elastic resin bands that are finer, have more layers, and are preinstalled into the cast shell before being applied to the arm.

Do you want to CREATE the Future of Education?

Industry is adopting additive manufacturing at an exponential rate, it is critical to be equipped with the skills needed in employment.

It is imperative that individuals experience these ground-breaking technologies today, to futureproof UK manufacturing in a globally competitive marketplace and address the many global issues we face.

CREATE Education are expert providers across the UK and Ireland, specialising in developing 3D technologies in education, to enable learners and empower educators.

Get in touch with our education specialists today on 01257 276 116 or email us at enquiries@createeducation.com.