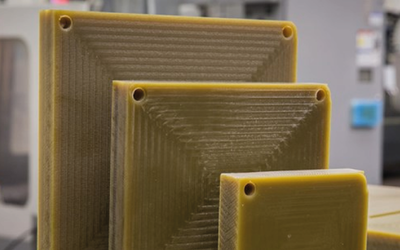

Sterra Range of Engineering Plastics

Engineering plastics with recycled content for sustainable production.

Technical Specifications

| Product Type | Sustainable Plastics |

| Base Materials | UHMW-PE, PEEK, PET, POM-C |

| Additional Features | Low friction, Electrostatic Dissipative, Minimal moisture absorption, wear resistance |

| Applications | Conveyor Systems, manufacturing, etc. |

Overview

Sterra® is a range of engineering plastics containing recycled materials to help manufacturers replace conventional plastics and attain their sustainability goals. The portfolio includes a wide range of engineering plastics featuring recycled content along with in-depth access to the lifecycle of the material. The Sterra portfolio enables manufacturers to compare recycled materials with their virgin counterparts. Based on a wide range of polymers, Sterra materials have applications in a versatile array of industrial processes and environments.

Promotes Circular Waste Reduction with Evaluation Tools

The Sterra collection of recyclable materials also comes with CORACAL, a carbon footprint dashboard. The dashboard allows manufacturers to evaluate various sustainable material options based on their needs.

The dashboard offers an initial estimate to help manufacturers identify the best options based on price, quality, etc. Moreover, there are various insights about the environmental footprints of each material. More importantly, all the information is backed by data, allowing the user to make more informed decisions about the material selection.

Diverse Range of Recycled Polymers for Industry-Specific Applications

The Sterra portfolio features up to nine different polymer types. These polymers act as base materials, combining with recycled materials to produce a sustainable manufacturing raw material. The base materials include

UHMW-PE

POM-C

PET

PEEK

TIVAR® Sterra DrySlide is a Recycled Ultra High Molecular Weight Polyethylene that is an internally lubricated and recycled lining material. It has a low friction coefficient and can withstand abrasion due to high wear resistance. It’s static dissipative and offers UV resistance.

TIVAR® Sterra UHMW-PE offers high abrasion and corrosion resistance. It is widely applied in wear-related components such as outrigger pads, strips, rails, guides, rollers, conveyors, chutes, hoppers, impact plates, and asphalt equipment. It offers good impact strength, minimal moisture absorption, and a low coefficient of friction.

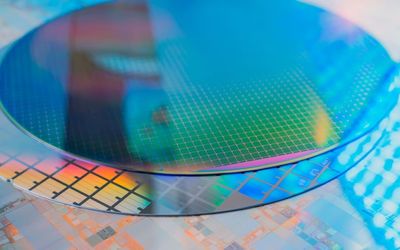

TIVAR® Sterra ESD UHMW-PE is a polyethylene with electrostatic dissipative properties and recycled UHMW-PE content. It is preferred as a lining material for conveyors, chutes, and hoppers prone to electrical charge build-ups. The material is of an electrostatic dissipative nature, features abrasion and wear resistance, and a low coefficient of friction.

Acetron® Sterra POM-C is a versatile recycled copolymer acetal grade highly valued for its absence of porosity, minimal moisture absorption, and exceptional machinability.

Ertalie® Sterra PET is an unreinforced, semi-crystalline PET with recycled content, known for outstanding wear resistance, a low coefficient of friction, high strength, and resilience against moderately acidic solutions. It can sustain high loads and has better strength retention at 180°F / 85°C compared to nylons or acetals.

Ketron® Sterra 1000 PEEK is an unfilled, general-purpose grade incorporating recycled materials, providing the utmost elongation and toughness within the PEEK family. It’s well-suited for applications requiring crucial ductility and inertness. It also boasts excellent chemical resistance.

KETRON® Sterra HPV PEEK is a recycled PEEK grade, reinforced with carbon fiber, graphite, and PTFE lubricants, featuring the lowest coefficient of friction and optimal machinability. It offers high mechanical strength and stiffness.

KETRON® Sterra CA30 PEEK features 30% recycled carbon fiber reinforcement. The inclusion of carbon fibers improves the compressive strength and stiffness while significantly reducing the expansion rate of PEEK. Key properties include exceptional chemical and wear resistance, diminished thermal expansion, and optimal load-bearing capabilities

References

Recommended Specs

Continue Reading

Submerged arc welding is a standard industrial process wherein an arc is formed between a workpiece and an electrode. It was invented in 1935 by the E. O. Paton Electric Welding Institute in Kyiv, Ukraine as a driving force behind the Second World War. One of the most notable applications of this invention is the T34 military tank.