University of Pittsburgh Speeds Microwell Fabrication with Micro 3D Printing

Julio Aleman, a Bioengineering PhD student needed two different microwell array system with individual wells that would support injection moulding of hydrogels and serve as “master moulds”

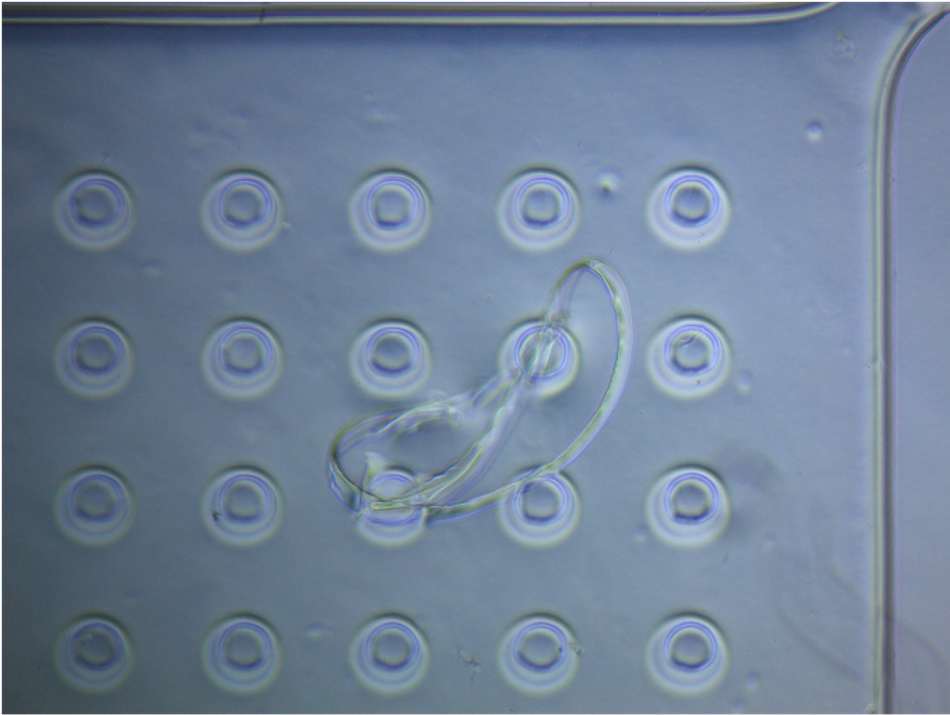

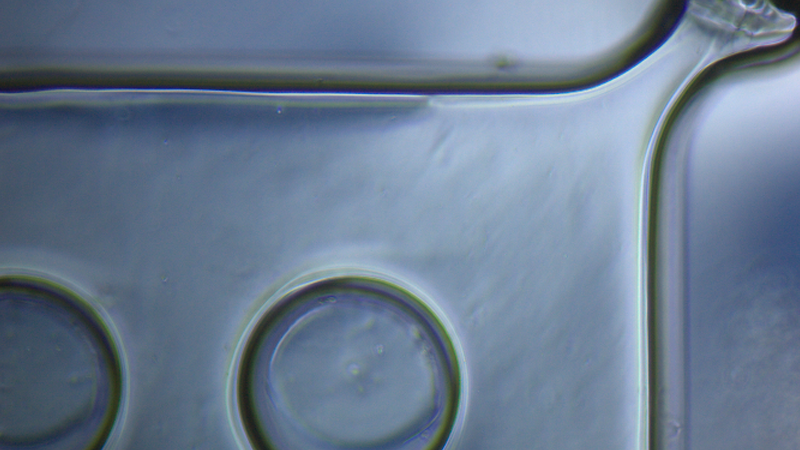

Hydrogel mould of 64-microwell array

Julio Aleman, a Bioengineering PhD student at the University of Pittsburgh Swanson School of Engineering is performing research in microphysiological systems.

Like many researchers, Aleman needed a microwell array system with individual wells that have a specific size, shape and density. In fact, Aleman needed two different microwell arrays that would support the injection moulding of hydrogels and serve as “master moulds” – the original moulds that he could replicate. In turn, these replicate moulds would be used for microwell fabrication.

To produce master moulds like this, photolithography (optical lithography or UV lithography) is often used. The process begins by spin coating a negative photoresist on a wafer to establish mould thickness and microwell depth. Photopatterning is achieved by light exposure through specialised high-resolution masks and finalised by chemical development of the master mould. Then, replicas of the master mould are made by casting pre-polymers over the negative template and polymerising them by thermal curing.

Polydimethylsiloxane (PDMS) silicone is the biocompatible polymer that is most often used. Typically, the production of master moulds and masks requires specialised facilities and equipment. Micro-injection moulding can also produce master moulds, but the tooling is expensive and time-consuming to produce.

An Alternative to Clean Room Photolithographic and Injection Moulding

Projection Micro Stereolithography (PμSL) from Boston Micro Fabrication (BMF) allows for the rapid photo-polymerisation of a layer of resin with a flash of ultraviolet (UV) light at micro-scale resolution. PμSL offers an alternative to photosoft lithography, etching, deposition, micro-injection moulding, and other traditional microfabrication methods.

PμSL, a form of micro 3D printing, can produce small components with fine features and tight tolerances that are otherwise impossible to create. PμSL is capable of achieving a resolution of 2µm~50µm and a tolerance of +/- 5µm~25µm, thus providing ultra-high-resolution that is mould-free and mask-free for fast prototyping and end-use parts.

Project Requirements for Two Master Moulds

The University of Pittsburgh project needed master moulds for replicate silicone moulds that, in turn, would be used to make biomaterial-based microwells. Normally, master moulds require a cleanroom and can be challenging to characterise. Researchers can’t perform profilometer measurements until the moulds are baked, and a mould with the wrong dimensions means lost time and money.

Julio Aleman’s project required fast turnaround times and high-volume production. Accuracy, resolution, and precision were critically important. Several PDMS replicas that were cured at 80° Celsius were needed and the repeated processes on the master mould had to have little to no impact on the dimensions while the master mould was also securely fixed in a substrate. Aleman knew that he would need moulds in two different sizes, and that the silicone moulds should allow for the bottoms of the hydrogel micro-wells to have constant and defined amounts of biomaterial once injected and polymerized onto a glass slide. After some preliminary discussions, he ordered parts from BMF.

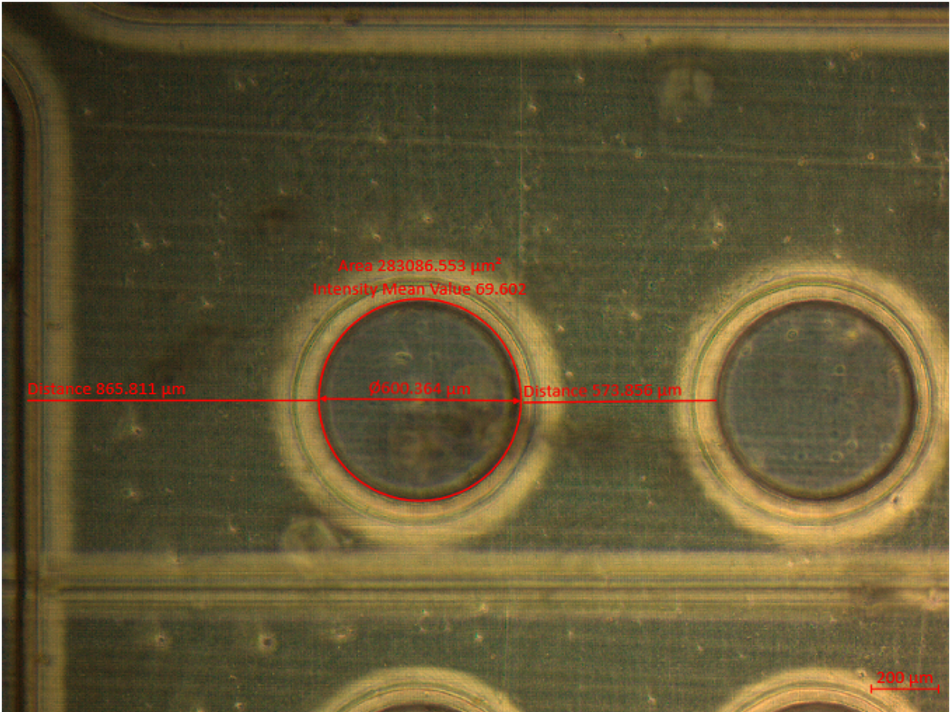

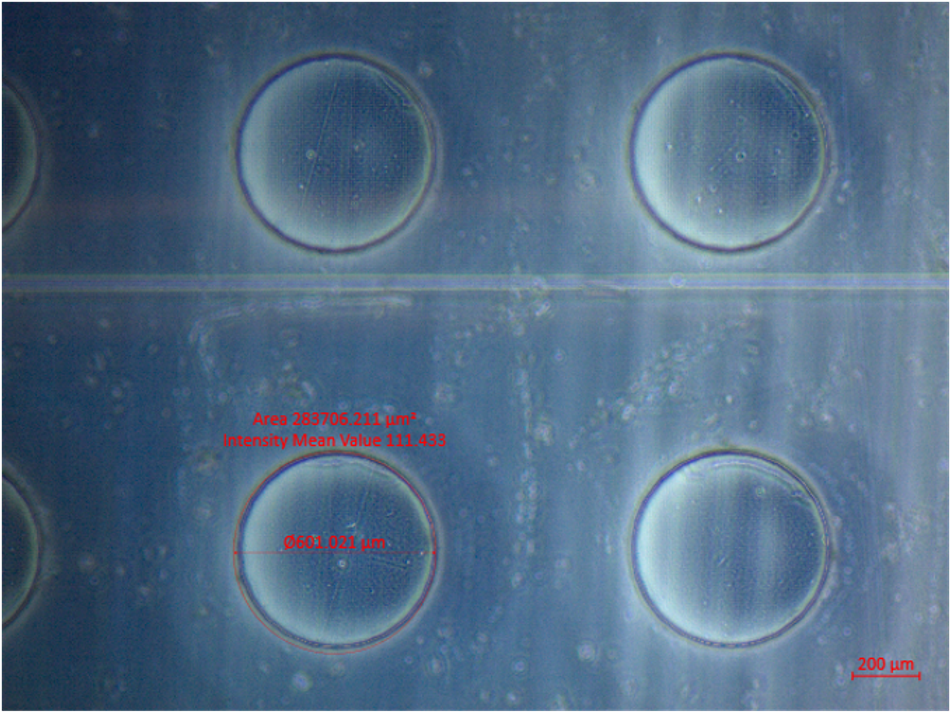

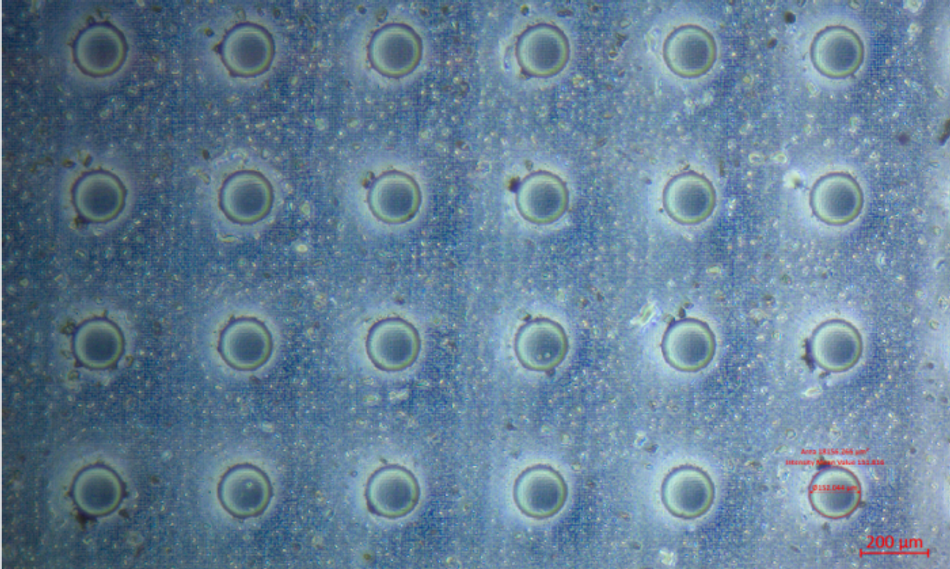

The master moulds that the University of Pittsburgh asked BMF to produce were square with a defined hole–pattern. The first mould was for a 64-microwell array. It had an overall area of 20 mm x 20 mm and a thickness of 1.65 mm. The diameter for each hole and the distance between holes was 600 microns, or 0.6 mm, and the base of each of the microwells had a height of 50 microns from the surface. The second mould was for a 484-microwell array. The overall area was the same as for the first mould (20 mm x 20 mm), but the thickness for the second mould was significantly less at 1 mm. There were also more holes – and the holes were smaller. These wells measured just 150 microns, or 0.15 mm, in diameter with a similar base height of 50 microns.

3D printed mould for 64-microwell array

Expert Advice and Flexible Material Selection

BMF’s application team reviewed the designs for the University of Pittsburgh moulds. They recommended increasing the thickness of the second mould to greater than 1 mm. Otherwise, a mould that is too thin may experience part distortion or internal stresses during the printing process. Aleman revised the thickness and BMF then created sample parts using GR resin, a high-performance engineering material that is black in colour, able to withstand temperatures up to 102°C, and that supports sterilising.

Because the COVID-19 pandemic limited Aleman’s access to university facilities, the graduate researcher limited his mould evaluation to microscopy. In turn, this meant that parts made of a dark resin would be more difficult to inspect. To support microscopic techniques, Aleman needed a resin that would allow more light to pass through so that the features of the resin mould could be more clearly seen. The solution was to use an HLT resin instead. This yellow resin from BMF offers greater transparency but still provides good impact strength, heat resistance, and support for autoclave sterilisation.

Speed, Accuracy and More

Julio Aleman was pleased with the quick lead time – the moulds were delivered in just two weeks. Instead of waiting months to get a single injection-mould, he could provide a master mould to each member of the research team. The moulds also exhibited dimensional stability and, unlike spin coating in photolithography, did not require multiple fabrication steps. After hard baking some master moulds in an oven overnight, Aleman attached them to a surface with double-sided electrical tape. The moulds experienced only a 10 to 20-micrometre reduction in size, and that may have been caused by pressing the moulds against the surface or the tape while the moulds were still malleable from baking.

Aleman also reported that after approximately 10 cycles of PDMS moulding, the BMF master moulds did not exhibit any bending or deformation. To prevent sticking, the replicate moulds were salinated with Vapor Phase Deposition (VPD). This treatment, which is also used with the SU8 moulds in photolithography, permitted the easy detachment of the PDMS moulds from the BMF master moulds. Aleman reported that the master mould with the larger features was easily salinated over one hour of exposure while the mould with smaller features required five hours or overnight exposure.

Proof-of-Concept for Your Next Project

As the University of Pittsburgh project demonstrates, researchers can use micro 3D printing to speed microwell array fabrication. If your application requires proof-of-concept parts such as master moulds, BMF can harness the power of PμSL technology on your behalf. We can also help you with material selection and recommend the best microArch printer from our growing family of ultra-high resolution 3D printers.

In an exclusive partnership with BMF, CREATE Education are sharing their knowledge, support and experience, to bring micro 3D printing technology to the forefront of their education community in the UK and Ireland, enabling breakthrough research and development.

CREATE Education are committed to supporting educators, educational institutions, outreach and community programs with the aim to bring cutting edge technologies throughout the world, such as 3D printers, into education.

To learn more about PμSL technology and micro 3D Printing for research, please contact CREATE Education’s specialists.