The Wide-Reaching Impact of Cloud Manufacturing

How hardware businesses are gaining a competitive edge with cloud manufacturing through streamlined request for quotes, greater agility, and more

The world has changed rapidly since the emergence of digital technologies like artificial intelligence (AI), the Internet of Things (IoT), machine learning, and the Cloud. This global shift, known as the 4th industrial revolution, is well underway, reinventing how we go about our daily lives and conduct business. Manufacturing, an often slow-to-change sector, is also gradually starting to adapt to increasingly smart processes and new paradigms. Cloud manufacturing is ushering in a new era of production that is creating many new opportunities across many industries.

Cloud manufacturing is not just the latest trend in manufacturing. It represents a new mode of operation that is enabling hardware businesses to attain unprecedented levels of agility, customization, scalability, and productivity through its use of intelligent, distributed manufacturing. As we’ll see in more detail, though cloud manufacturing is still largely considered a still-emerging technology, it is already offering a competitive edge to product developers, startups, hardware companies, etc., helping them to evolve into cutting-edge, next-generation businesses.

Where does cloud manufacturing stand today?

Cloud manufacturing is an important piece of the larger framework of cloud technologies. But while cloud technology has become mainstream—as evidenced by our daily reliance on it to store photos and files—cloud manufacturing is still establishing itself and finding its footing. This slower proliferation is due in part to technological hurdles—especially where software and hardware intersect—but a more significant challenge to adoption has been hesitancy on the part of the manufacturing industry.

Manufacturing companies—especially leaders with well-established legacy systems—remain conservative when it comes to changing how they operate and introducing a whole new service-based paradigm. For this reason, it is important to push for greater awareness and knowledge of cloud manufacturing and both the short- and long-term benefits it presents.

Cloud manufacturing itself is derived from the principles of cloud computing and consists of an integrated virtual network of manufacturing resources and capabilities. In short, cloud manufacturing provides a digital cloud infrastructure that connects hardware businesses to manufacturing services facilitating on-demand production on a pay-per-use model.

However, cloud manufacturing is also much more. The technology creates entire manufacturing ecosystems that encompass every stage of the hardware production life cycle, from concept to prototyping, to engineering validating and testing (EVT), to design validation and testing (DVT), to product validation and testing (PVT), to final production and scaling. This broad scope means that cloud manufacturing can meet the needs of a wide range of hardware businesses, regardless of their size or resources.

The next generation of hardware companies

Cloud manufacturing is revolutionizing the way that hardware companies operate. Whereas the primary paths to bringing a product to market were to either invest in manufacturing equipment and trained technicians or set up a complex supply chain, businesses now have a more efficient option. They can connect with various manufacturing services, which make their prototype or product on-demand using the process and materials of their choice lowering the barrier to entrance to cutting edge technology.

One of the main benefits of cloud manufacturing is agility, and this manifests in several ways. For one, hardware manufacturers can more easily produce parts without worrying whether they have the specific equipment, materials, and expertise available in-house. For example, German Bionic, a company that produces non-medical exoskeletons, decided to switch its products from aluminum to carbon fiber. Because it had not invested in aluminum manufacturing systems in the first place, it was able to make this change without losing money.

This case study also hints at another impact cloud manufacturing is having: because hardware businesses utilizing cloud manufacturing have not invested capital in expensive machines, they can make their product development decisions based on the best result, rather than what capabilities and materials they are tied to. In other words, cloud manufacturing re-centers the end product without any dependency on legacy systems.

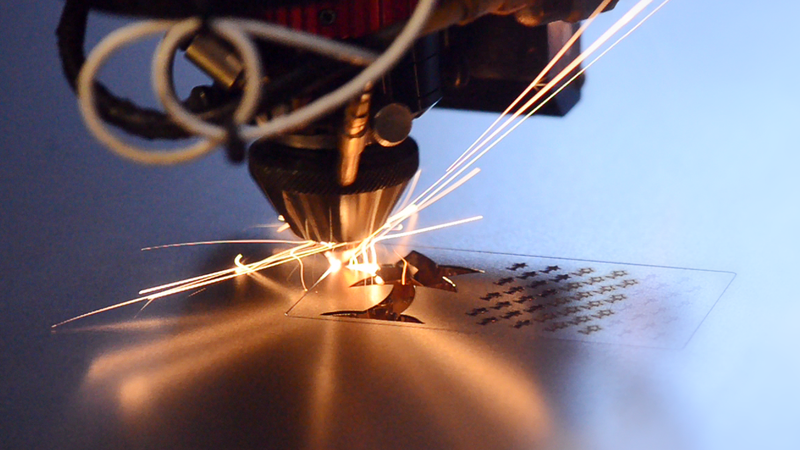

Cloud manufacturing also enhances agility by giving hardware companies access to more manufacturing capabilities than ever before—including CNC turning, CNC milling, 3D printing, and sheet-metal laser-cutting—without having to put up any up-front investments for the equipment or having to invest in skilled staff. It also saves hardware companies from the time-consuming and expensive process of having to find world-class manufacturers by themselves should they ponder pursuing a traditional outsourcing approach. This cost reduction unlocks new levels of accessibility for state-of-the-art manufacturing capabilities and helps to democratize manufacturing.

Newcomers or smaller businesses without the same capital or resources as high-volume hardware companies can now leverage the same state-of-the-art processes and materials by using cloud manufacturing platforms. In many cases, they can even work with the same services, which will level the playing field and, again, prioritize the product above all. This will inevitably promote the development of new products at faster rates, leading to greater competition and, ultimately, lower costs.

Cloud manufacturing is transforming production dynamics

Beyond the clear benefits of cloud manufacturing we’ve laid out, the technology also has other consequences that are transforming the relationship between manufacturing services and hardware businesses.

For starters, cloud manufacturing completely changes the request for quote (RFQ) process. No longer do customers have to reach out to various manufacturing services or suppliers to negotiate the terms of each production project. With cloud manufacturing, the quoting process is simplified and automated, providing full pricing transparency via a single portal. Customer requests are analyzed by AI-driven software, which identifies the best manufacturing solution and service based on a range of criteria. Using the ‘hourly model’, an hourly rate is then generated based on the customer-specific data, including process type, material, complexity, etc. Cloud manufacturing also enhances production transparency, keeping the customer up to date on their production order.

Cloud manufacturing also opens the door to superior product design through collaboration. Designers and engineers from around the world can connect to the cloud to contribute design ideas for complex industrial systems. This fosters innovation and brings together minds and ideas from around the world that may otherwise have never connected. Further, by encouraging the sharing of global manufacturing resources, cloud manufacturing can improve many aspects that lead to greater innovation, including faster time-to-market, greater market competition, and lower manufacturing costs.

Making smart custom part procurement decisions with KREATIZE

One of the companies contributing to the growth and advancement of cloud manufacturing is Germany-based KREATIZE. The innovative firm, founded in 2015 by Simon Tüchelmann (CEO) and Daniel A. Garcia Rodriguez (CTO), has built a platform that digitizes the manufacturing process for custom parts and products. With a network of +200 vetted partners, and offices in Germany (Berlin and Balingen) and Poland (Wroclaw), KREATIZE aims to establish more agile, intelligent manufacturing solutions within Europe.

By utilizing the service-based, pay-per-use model of cloud manufacturing, KREATIZE customers can request hourly rate quotes and easily order their parts from trusted manufacturing partners. The nature of the process ensures that product designs are protected and that there is full transparency throughout the production process.

KREATIZE’s latest white paper, “Cloud Manufacturing: Its Technology and Impact on Hardware Businesses” delves further into the background and current state of cloud manufacturing as well as the many ways the technology is influencing and revolutionizing manufacturing practices. Above all, the insightful report aims to create greater awareness of cloud manufacturing, utilizing knowledge to alleviate existing hesitancies about the highly promising, innovation-driving manufacturing approach.

References:

KREATIZE GmbH. (2021). Cloud Manufacturing: Its Technology and Impact on Hardware Businesses. [White Paper]