The Peer-Powered Network: Why Collaboration Shouldn't Stop at the Company Wall

Discover how hardware teams accelerate development by enabling external partners to collaborate in the same live design environment—not through files, but shared context.

Modern hardware development doesn’t happen inside a single team anymore. It moves across internal groups, external partners, contract designers, contract manufacturers, suppliers, and specialists who step in only when needed. Each collaborator brings their expertise and helps shape the final product. Yet most electronics development environments still treat everyone outside the company as an afterthought.

This split between internal teams with full access and external teams working with limited information slows handoffs, forces repeated work, and causes preventable misunderstandings. It forces engineers to spend their time packaging files instead of solving problems, and it delays small decisions that could be made immediately until the next meeting.

The irony is that everyone involved wants to collaborate. But software, licensing, and disconnected workflows make it unnecessarily hard. What should feel like one extended team often feels like a chain of isolated contributors, with good intentions.

For hardware teams under pressure to deliver quickly, that division isn’t good enough.

Why External Collaboration Breaks Down

Most hardware teams work with external partners. The challenge is that these contributors rarely operate with the same level of context as the internal team.

A vendor might model the enclosure based on an outdated STEP file. A contractor may deliver a layout that unknowingly mismatches the latest BOM. A manufacturer might flag a DFM issue only after the design has already progressed. These delays are not from carelessness. They happen because information reaches decisionmakers too slowly, too inconsistently, or too unexpectedly.

External collaborators typically work without direct visibility into evolving decisions. They rely on screenshots, email attachments, exported files, and manual explanations. By the time they receive feedback, the work has moved on. In this environment, internal teams end up slowing down just to support the people meant to support them — packaging files, reconstructing decisions, and rebuilding context that should never have been lost.

Hardware Needs a Peer-Powered Network

Modern electronics development doesn’t follow a straight line. It moves across disciplines and organizations, involving people who participate at different moments for different reasons. But most development environments still assume that meaningful collaboration only happens inside the company.

A peer-powered network—with a “network effect” making team membership richer with each new member—takes the opposite approach. It recognizes that contractors, suppliers, and manufacturing partners are not so peripheral. They’re often essential contributors who shape the product just as meaningfully as internal engineers do.

When these peers can see the current design, understand constraints, and contribute directly, the entire process changes:

suppliers highlight lifecycle risks before designs lock;

mechanical partners validate constraints as layout evolves;

contract designers work in parallel, not in sequence; and

manufacturers flag DFM concerns early, when change is easy.

Younger engineers already work this way in every other modern tool they use. They expect collaboration to be fluid, real-time, and inclusive. A modern, peer-powered platform brings that expectation into hardware — not as a luxury, but as a requirement for moving quickly and avoiding preventable delays.

What Collaboration Looks Like When Everyone Can Actually Participate

When external contributors have access to the same living design environment, they stop guessing and start contributing.

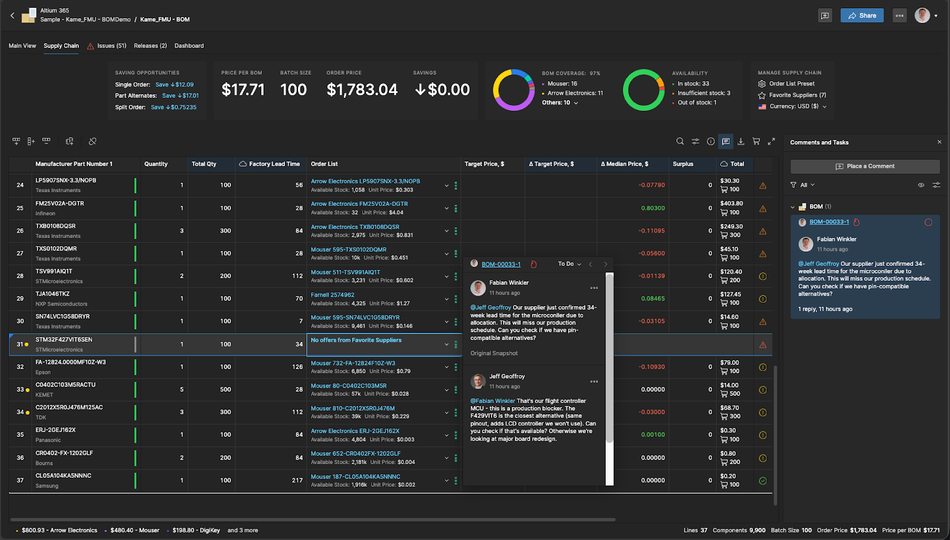

A mechanical partner can open the enclosure and PCB designs together, leave comments tied directly to the geometry, and track how changes evolve. A contract PCB designer can co-author the layout with the internal team instead of waiting for a scheduled handoff. Procurement partners can evaluate BOM changes as they happen, rather than react in haste to outdated spreadsheets. A manufacturer can surface DFM risks in the same environment where engineers make decisions — days or even weeks earlier than they’re used to.

The effect is simple: progress becomes continuous instead of intermittent. Feedback arrives at the right moment, not after the fact. The design stays aligned across organizations instead of fragmenting into disconnected versions. Collaboration feels less like a sequence of handoffs and more like a shared workspace where everyone moves together as one team.

When context isn’t locked inside the company — when it’s securely shared everywhere — the work accelerates naturally.

How Agile Teams Enables This Peer-Powered Model

Altium Agile Teams supports this vision for broader, more fluid, peer-to-peer collaboration by giving internal and external contributors a shared environment that’s both accessible and controlled.

External partners can be invited as guest collaborators with permissions tailored to their role. They see only what they need to see, while still contributing directly within the same workspace as the core engineering team. Every action is recorded, providing clarity without introducing friction.

Design reviews take place directly in the browser, with comments attached to real design objects instead of scattered across email threads. ECAD and MCAD changes stay synchronized, giving mechanical and electrical partners a shared foundation instead of dueling versions. Managed component libraries keep procurement conversations grounded in accurate lifecycle and sourcing data. And because Agile Teams supports large groups of collaborators without licensing obstacles, suppliers and contractors can participate without slowing velocity or adding cost.

This isn’t collaboration through exported files. It’s collaboration through a connected experience where context travels with the work, and every contributor participates meaningfully in the flow of product development.

Why This Matters for the Next Generation of Engineers

For early-career engineers, work isn’t defined by departments—it’s defined by impact. They want to learn from suppliers, from manufacturing specialists, from contractors who’ve solved the same problem in similar projects.

A peer-powered network amplifies their influence.They see more. They understand more. They contribute more.

Instead of waiting their turn in a fragmented chain, they participate in the same shared environment as everyone else. They develop skills more rapidly, improve their decisions, and build the kind of engineering culture they remember from university—where innovation spreads between peers, instead of bottlenecking.

Collaboration Doesn’t Stop at the Company Wall — and Innovation Shouldn’t Either

Hardware development will always require many disciplines and many partners working together as a team. What determines speed and success is how smoothly those people can work together.

When external collaborators are excluded by default, every step slows down. When they’re invited into the same connected environment, with the appropriate controls, everything accelerates.

A peer-powered network turns partners into contributors, contractors into teammates, and suppliers into early problem-solvers. It removes the walls around the engineering process so teams can move quickly, confidently, and as one. Participants feel a strong desire to do good work and to stick with the team.

Start your free trial of Altium Agile Teams and see how connected, cross-organizational collaboration transforms the way hardware teams build products together.