The Additive Manufacturing Process Chain and Its Industry Interfaces

Explore the additive manufacturing process chain, from digital design and materials to post-processing, inspection, and scaling, and understand how cross-industry integration drives industrial AM adoption.

Additive manufacturing (AM) is increasingly understood not as a standalone production technology, but as a system-level industrial workflow composed of tightly coupled technical and organizational elements. Successful industrial application depends on the coordinated interaction of digital design, materials, equipment, software, post-processing, inspection, and production integration. Decisions made at any stage of this process chain directly influence part quality, cost structures, scalability, and qualification outcomes.

As AM adoption expands across multiple industrial sectors, the interdependence between these stages becomes more pronounced. Design assumptions must reflect material behaviour and process constraints; machine performance is inseparable from feedstock characteristics; post-processing and inspection requirements feed back into upstream planning. Consequently, visibility across the full AM process chain is increasingly critical—not only for technology providers, but also for AM users seeking to industrialize applications [1][2].

This article provides a structured overview of the additive manufacturing process chain, clarifies where different types of companies and stakeholders operate within it, and illustrates why cross-value-chain and cross-user-industry interaction play a central role in accelerating AM adoption and scaling.

Join early as an exhibitor and get discounted access to Formnext 2026

Registration for Formnext 2026 is now open. Secure your spot by March 2 and enjoy exclusive conditions with up to 15% discount.

Register here

Overview of the End-to-End Additive Manufacturing Process Chain

The additive manufacturing process chain can be described as a continuous sequence of interlinked stages, each influencing downstream performance and feasibility. At a high level, these stages include digital design and data preparation, materials development and qualification, AM systems and process control, post-processing and finishing, inspection and quality assurance, and finally automation and production scaling.

While many organizations specialize in individual segments of this chain, industrial AM outcomes depend on system-level optimization rather than local improvements. Constraints or inefficiencies in one stage often shift complexity or cost to another. As a result, both technology providers and AM users benefit from a holistic understanding of how individual solutions fit into the broader production context [2][3].

Digital Design, Engineering, and Data Preparation

The AM process chain begins with a digital workflow that translates functional requirements into manufacturable geometries. This includes computer-aided design, generative and topology-optimized approaches, simulation of thermal and mechanical behaviour, and build preparation activities such as slicing and parameter definition.

Companies operating in this segment include engineering software developers, simulation and digital twin providers, and workflow and data management platforms. Recent developments emphasize tighter integration between design tools and process simulation, increasing use of AI-assisted design methods, and growing demand for traceability and digital continuity.

Design decisions made at this stage have direct implications for material selection, process stability, post-processing effort, and inspection strategies, reinforcing the need for early-stage collaboration across the process chain [1][2].

Materials: Feedstock Development, Qualification, and Supply

Role of Materials in AM Performance and Economics

Materials used in additive manufacturing including powders, filaments, resins, and other feedstock forms play a decisive role in determining mechanical properties, surface quality, dimensional repeatability, and overall process stability. Variations in particle size distribution, chemical composition, rheology, and thermal behavior directly influence build consistency and productivity. As a result, material selection is closely tied to economic considerations such as build reliability, scrap rates, and post-processing effort. In industrial AM environments, material–process compatibility is therefore a prerequisite for reproducible performance and cost-effective production [1][2].

Types of Companies and Capabilities in This Segment

The AM materials segment comprises a diverse ecosystem of stakeholders. These include material producers and compounders supplying standardized feedstocks, alloy and polymer developers designing application-specific materials, recycling and material lifecycle specialists addressing reuse and sustainability, and testing and qualification service providers supporting industrial and regulatory requirements. Together, these actors enable material availability, performance validation, and compliance with industry-specific standards [1][2].

Current Technical and Market Developments

Current developments in AM materials reflect the technology's growing industrialization. There is an increasing focus on application-specific materials, such as high-temperature polymers and high-strength metal alloys, tailored to demanding operating environments. At the same time, industries including aerospace, automotive, and medical are driving demand for consistent material qualification approaches and standardized property data. Sustainability considerations—such as material reuse, recycling, and efficiency are also gaining importance. These trends reinforce the need for closer coordination between material suppliers, machine manufacturers, and end users [2][3].

Interface with Other Process Chain Stages

Material behaviour in AM is strongly dependent on machine architecture and process parameters, influencing build stability and achievable part quality. Material selection also affects downstream post-processing requirements, inspection strategies, and qualification workflows. Early-stage collaboration between material developers, equipment manufacturers, and AM users is therefore critical for successful material adoption and for minimizing iteration cycles across the process chain [1][3].

Additive Manufacturing Systems and Process Control

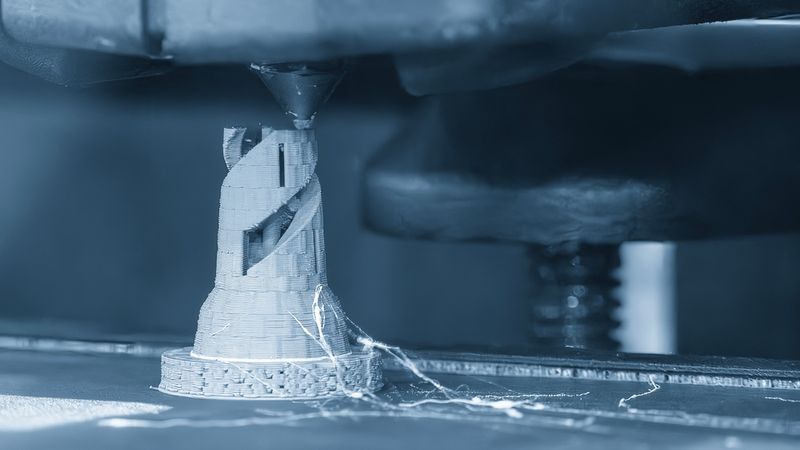

AM systems form the physical core of the additive manufacturing process chain, translating digital designs and qualified materials into functional components. These systems include polymer-, metal-, and hybrid or multi-material platforms, whose performance depends on machine architecture, energy delivery, motion systems, and control strategies.

Key stakeholders include machine manufacturers, suppliers of critical subsystems such as lasers, optics, and motion-control components, and providers of sensing, monitoring, and process-control technologies. Together, they define the operational capabilities of AM equipment and its suitability for industrial deployment.

As AM progresses from prototyping to serial production, process stability and repeatability remain central challenges. Accordingly, in-situ monitoring, process data acquisition, and closed-loop control are increasingly applied to detect and correct deviations, supporting consistency, traceability, and documentation required for industrial applications.

Rather than detailing individual technologies, AM systems are increasingly framed within structured technology frameworks that classify equipment by process principles and application domains. Such AM field or technology guides support comparison of system capabilities and alignment with materials, applications, and downstream process requirements. Within the Formnext ecosystem, this framing facilitates informed technical exchange across the AM process chain.

Interoperability with adjacent process stages is therefore essential. Integration with digital design tools, qualified material systems, and automated post-processing, inspection, and production management environments underpins scalable and industrialized AM workflows [1][3].

Post-Processing and Surface Finishing

Post-processing is an integral component of the AM process chain rather than an auxiliary step. Activities such as support removal, heat treatment, surface finishing, coating, and machining are often decisive for functional performance and certification.

This segment involves equipment manufacturers, contract service providers, and automation specialists. Emerging trends include increased automation of post-processing workflows, standardization to reduce variability, and tighter integration with upstream production planning.

Post-processing requirements frequently influence design rules and material selection, further underscoring the interconnected nature of the AM process chain.

Inspection, Quality Assurance, and Certification

Inspection and validation are essential for industrial AM adoption, particularly in safety-critical or regulated applications. Technologies involved include non-destructive testing, metrology, dimensional inspection, and process data analysis.

Relevant stakeholders include inspection equipment manufacturers and software providers, as well as testing and certification organizations. Quality data increasingly serves as a feedback mechanism into design, material selection, and process parameter optimization, linking this stage closely to earlier steps in the chain.

Alignment with regulatory frameworks and customer qualification requirements remains a key driver of innovation in this segment [1].

Automation, Integration, and Production Scaling

As AM transitions from isolated systems to integrated production environments, automation plays a central role. This includes automated material handling, build changeover, post-processing integration, and digital production management.

Stakeholders in this area include robotics and automation providers, systems integrators, and manufacturing IT and MES vendors. For companies aiming at serial production, integration across the full process chain becomes a strategic necessity rather than an optional enhancement [2] [3]

Cross-Value-Chain Interaction and Industry Platforms

Innovation in additive manufacturing increasingly occurs at the interfaces between process stages and between user industries. Beyond coordination among technology providers, exchange between AM users from different industrial sectors has become particularly valuable. As AM remains in a relatively early stage of adoption for many applications, peer-to-peer interaction enables the sharing of practical experience, lessons learned, and validated use cases.

Horizontal platforms that bring together material developers, machine manufacturers, software providers, post-processing specialists, inspection experts, and AM users across industries create environments where these interactions can occur in context. Formnext is positioned as such a neutral, technically oriented meeting point, supporting exchange across the full AM process chain and between diverse user industries [3].

By enabling dialogue not only along the value chain but also across industrial application domains, such platforms contribute to risk reduction, inspiration of new use cases, and accelerated industrial learning.

Exhibitor Relevance and Timing Considerations

For companies operating at different stages of the AM process chain, participation in industry platforms is increasingly evaluated as a strategic planning decision. Early engagement supports visibility within specific process segments, facilitates targeted interaction with relevant stakeholders, and aligns participation with internal development cycles.

In this context, timing considerations such as early commitment windows are part of broader planning and positioning strategies rather than standalone commercial messages.

References

ISO/ASTM 52900:2021(E). Additive Manufacturing — General Principles — Fundamentals and Vocabulary. ISO & ASTM International.

Gibson, I., Rosen, D., & Stucker, B. Additive Manufacturing Technologies. Springer.

Formnext (Messe Frankfurt). AM Field Guide and Exhibitor Information.

Wohlers Associates. The Seven Additive Manufacturing Processes.