SKYRON's Rotary Arm: Elevating Precision in Contact-Based Inspections

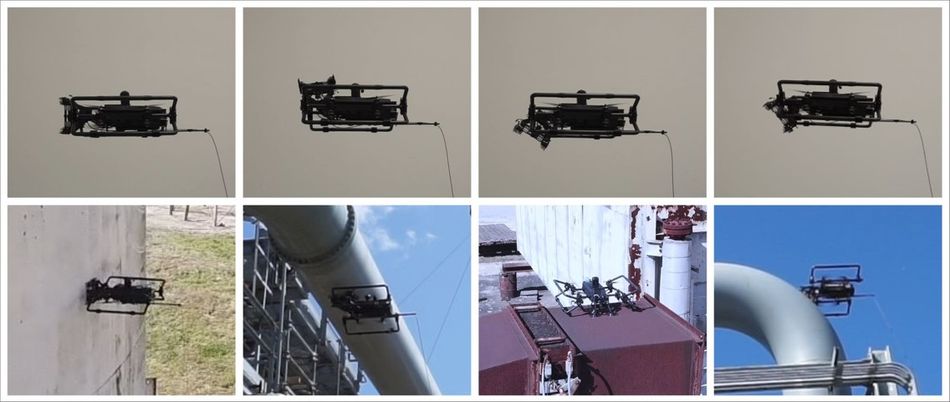

The Rotary Arm has the ability to attach to different surfaces shapes, vertical, horizontal, angular, and even curved surfaces.

SKYRON flying towards asset

In the Non-Destructive Testing (NDT) industry, where the pursuit of enhanced safety and inspection efficiency drives innovation, SKYRON's Rotary Arm stands as a true game-changer. This integral component within SKYRON's toolkit improves the precision and accuracy during inspection.

SKYRON is an Intelligent Flying Robot meticulously designed to execute Non-Destructive Tests with unparalleled accuracy, meeting and surpassing industrial asset inspection standards and elevating safety in the inspection process. What sets this remarkable robot apart is its capability for performing contact-based inspections across diverse settings, even in the most challenging conditions.

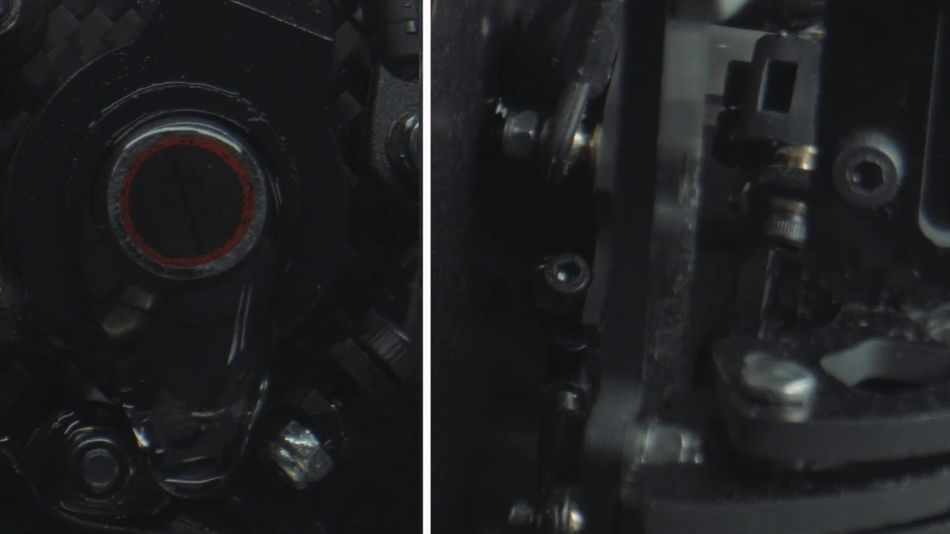

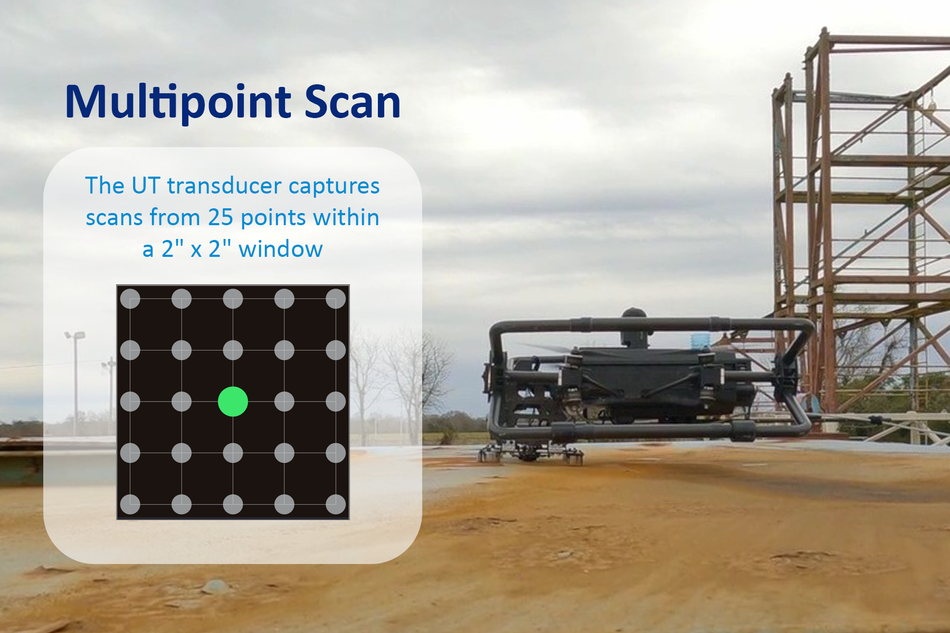

At the heart of SKYRON's prowess lies the Rotary Arm. What truly sets the Rotary Arm apart is its ability to attach to different surfaces shapes, vertical, horizontal, angular, and even curved surfaces. The exceptional adaptability of the Rotary Arm ensures accurate inspection readings. This is supported by a patented attachment mechanism that ensures precision. Consequently, this innovation simplifies and enhances inspections in challenging locations, making them more comprehensive.

The Rotary Arm capabilities extend to perform Dry Film Thickness (DFT) inspections. Taking Echo-to-Echo measurements, the arm presents a comprehensive solution to coating assessments, all while adhering to the highest standards of precision.

In a landscape where industries continuously evolve, demanding increasingly rigorous and safer inspection methodologies, SKYRON's Rotary Arm emerges as a pioneering force. Its multifaceted capabilities, encompassing attachment versatility, expansive area scanning, and unyielding adaptability, constitute the foundation of a new era in contact-based inspections. SKYRON is prepared to change how inspections are typically done, setting a completely new level of quality, accuracy, and safety.