Simulate at the Speed of Design: A New Era of Product Development

Explore the innovations that are already helping companies across various industries streamline their processes, reduce time-to-market, and make better-informed design decisions at Altair's global, virtual event Simulate at the Speed of Design, May 15th.

Today, product development is not just about designing components; it’s about orchestrating various elements, including mechanical, thermal, electromagnetic, and manufacturing systems, into a seamless final product. With every product becoming increasingly interconnected, the simulation must evolve to keep up with these complexities.

There is a growing need for smarter, faster, and integrated simulation tools to address these challenges. These tools must enable engineers to perform comprehensive analyses early in the design phase, allowing for rapid iteration and decision-making. Altair’s Simulate at the Speed of Design 2025 global virtual event is designed to showcase how companies can leverage the latest advancements in simulation technology to accelerate their product development cycles. Companies can move from initial concept to final creation faster and smarter by embracing these advanced solutions.

This article will explore the innovations that are already helping companies across various industries streamline their processes, reduce time-to-market, and make better-informed design decisions.

Digital Product Development: The Innovation Imperative

As industries continue to evolve, modern engineering teams are facing unprecedented challenges in the product development process. Fragmented tools, lengthy development cycles, and bottlenecks at later simulation stages limit the innovation potential. To stay competitive, companies must compress their timelines, lower costs, and enhance the performance of their products, all while ensuring seamless integration between different engineering domains.

Historically, product development teams have been constrained by siloed systems, including mechanical engineering teams using one set of tools, thermal analysis teams using another, and manufacturing engineers relying on separate platforms altogether. This disjointed approach leads to inefficiencies and increases the risk of errors when different departments fail to share critical data.

The pressure to compress timelines and reduce costs has never been greater. Companies must create smarter products faster, which means rethinking how simulation tools are used across the product lifecycle. The solution lies in converged, integrated simulation tools that allow engineers to collaborate across domains and analyze their designs from multiple angles, such as mechanical, thermal, electromagnetic, and manufacturing, without needing multiple, disconnected tools.

To address these challenges, Altair is leading the charge with its advanced, cloud-based, AI-enhanced simulation tools that make it easier to simulate early in the design phase, iterate quickly, and confidently innovate. These tools allow engineers to explore multiple design options and test them against real-world scenarios much earlier in the development process, significantly reducing time-to-market while improving the quality and performance of the final product.

Simulation at the Speed of Design: Altair’s Vision

Altair’s vision for the future of simulation is: “to make it fast, intuitive, and accessible to all engineers, regardless of their expertise level”. Through innovations like meshless simulation (SimSolid), electromagnetic solvers (Feko), and multiphysics integration, Altair has developed a comprehensive set of tools that empower engineers to perform complex simulations with minimal effort and maximum accuracy.

SimSolid, for example, is a meshless structural analysis tool that simplifies the simulation process by eliminating the need for complex geometry simplifications and mesh generation. This tool allows engineers to analyze full CAD models without requiring deep finite element analysis (FEA) expertise. The result is a much faster and more intuitive simulation process that accelerates design iterations and reduces the time spent on simulations.

In addition to SimSolid, Altair offers Feko, an electromagnetic simulation tool that allows engineers to model and simulate electromagnetic interactions. Feko has become indispensable in telecommunications, automotive, and aerospace industries, where electromagnetic compatibility (EMC) is a critical consideration.

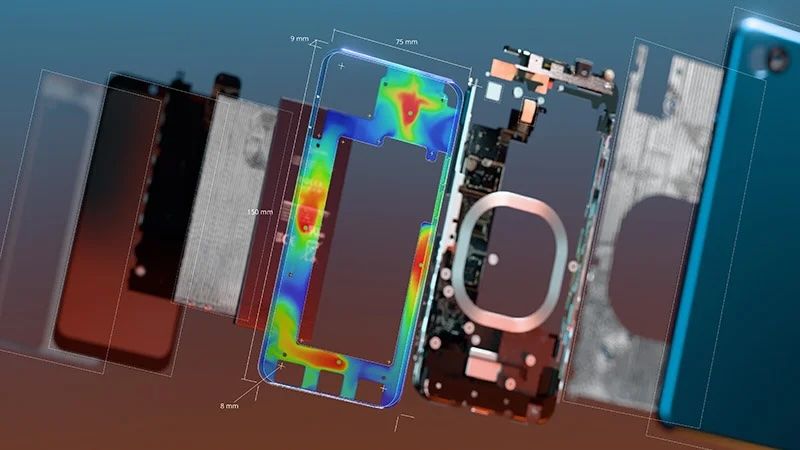

Altair’s tools also feature multiphysics integration, which allows engineers to simulate multiple physical phenomena simultaneously. This is particularly important in modern product development, where products often involve complex interactions between mechanical, thermal, and electromagnetic systems.

Through cloud-based solutions and AI-enhanced capabilities, Altair enables engineers to simulate early, iterate fast, and make more confident decisions. The integration of AI allows for faster convergence of simulations, ensuring that engineers can explore more design possibilities in less time.

Transforming Industries with Simulation: Real-World Success Stories:

Companies use advanced simulation tools to optimize designs, improve accuracy, and stay competitive, making simulation an essential part of modern engineering workflows. Below, we explore real-world success stories of how companies have leveraged Altair’s simulation solutions to drive innovation and efficiency in their product development processes.

Astra: Building Rockets 10x Faster with Sim Solid:

Astra, an aerospace company known for its low-cost, high-efficiency launch services, faced a major challenge in accelerating their product development cycle. The company needed a simulation tool that could provide quick and accurate insights into their rocket components' structural and thermal behaviour, enabling informed decisions early in the design process.

Adopting Altair SimSolid allowed Astra to perform structural and thermal analyses on full CAD models without mesh generation or complex simplifications. This approach empowered engineers to analyze designs faster and with greater accuracy, significantly reducing development time for new rockets. Consequently, Astra achieved the successful Spaceflight-1 launch in record time.

Mabe: Optimizing Appliances’ Wireless Connectivity with Feko

Mabe, a leading home appliance manufacturer, sought to enhance the wireless connectivity of its range hoods by integrating a new communication module. However, the metallic structure of the range hood posed a significant challenge to maintaining a strong and reliable wireless signal. To overcome this, Mabe used Altair Feko to simulate the electromagnetic behaviour of the module in various placements within the hood.

Mabe’s engineering team determined the optimal placement of the wireless module to minimize interference and ensure reliable communication by simulating the electromagnetic interactions. The results of these simulations allowed Mabe to design a more efficient and functional product, driving their evolution into smart, connected appliances

Technology Showcases: What to Expect at SSD 2025

At SSD 2025, Altair will present a wide range of groundbreaking technologies that showcase the future of simulation. The event will feature live demonstrations, expert Q&A sessions, and hands-on experiences. Here are some of the key technology showcases to look forward to:

AI-Powered Design Techniques

Generative AI-powered design techniques will be demonstrated, focusing on lightweight and performance optimization. These technologies are transforming industries like automotive and aerospace, where weight reduction and material efficiency are critical.

Assembly-Level Mesh-Free Structural Analysis

SimSolid’s unique mesh-free approach will be highlighted, demonstrating how it enables early design decisions and eliminates simulation bottlenecks that typically occur in traditional FEA tools.

Spotlight: Panel Discussion - The AI-Powered Future of Manufacturing Johannes Eschl I Data Analyst, BMW Dr. Sam Ramrattan I Professor, Western Michigan University Discover how AI is revolutionizing manufacturing process simulations in stamping, casting, and beyond. This panel explores how AI-driven predictive simulations can identify defects early, optimize tool design, and reduce costly trial-and-error iterations. With solutions like Altair PhysicsAI, which learns directly from 3D meshes, simulation becomes faster, more accurate, and far more adaptable. As smart manufacturing takes center stage, integrating AI into your simulation workflow is not just innovative — it’s essential. |

Manufacturing Simulation & Feasibility

Attendees will learn how virtual prototyping can help identify manufacturability issues before tooling, saving both time and money in the production process.

Multiphysics Simulation for Electronics

The event will showcase how thermal, structural, and electromagnetic simulations can be integrated to optimize products such as electric vehicles, IoT devices, and high-frequency components.

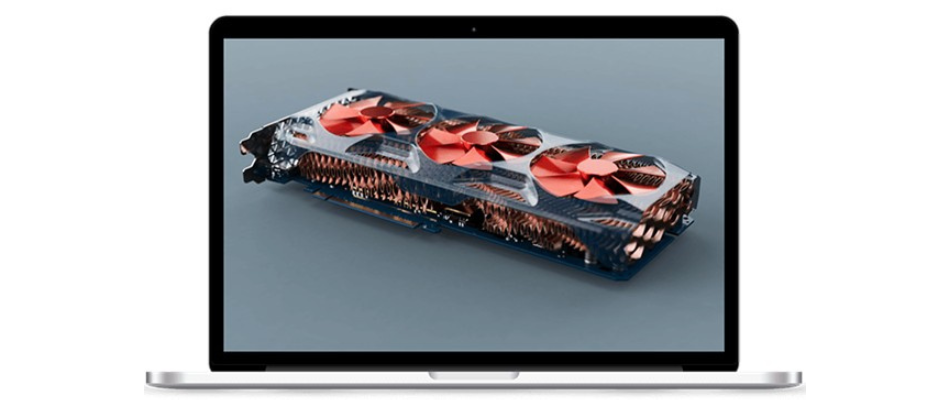

Power Electronics & Motor Drive Simulation

Altair will highlight its tools for optimizing power electronics and motor drive systems, which are crucial for applications like electric mobility, where efficiency and reliability are paramount.

Semiconductor Functional Verification

Scalable validation tools for semiconductor design will be featured, focusing on reducing time-to-silicon and improving first-pass success in chip manufacturing.

All of these technologies will be demonstrated live, allowing attendees to experience the future of simulation firsthand.

Keynote Spotlight: Julia Koerner’s Digital Renaissance:

Julia Koerner is a pioneer at the intersection of fashion, technology, and architecture. As the founder of JK3D and an adjunct professor at UCLA, she has innovated 3D printing and digital fabrication in fashion and architecture. Her collaborations with Paris Haute Couture and Marvel’s Black Panther have redefined the possibilities of digital design. At the same time, her “Cactus Homes” initiative seeks to make sustainable, affordable housing a reality through 3D-printed materials.

Koerner’s innovative work is an excellent example of how digital workflows and advanced simulation tools can push the boundaries of what is possible in design. She has been able to explore new design possibilities that were once unimaginable by embracing digital fabrication and simulation technologies. Her approach aligns perfectly with Altair’s mission to empower engineers and designers to innovate quickly and confidently.

At SSD 2025, Koerner will share her insights on how simulation and digital design workflows can enable designers to break free from traditional constraints and create solutions that have a meaningful impact on society.

Why Attend? Top Reasons to Join SSD 2025

SSD 2025 offers attendees the chance to experience the cutting edge of simulation technology. Here are the top reasons to attend:

Global Virtual Platform:

Access the event anywhere and engage with experts and peers worldwide.

Cross-Disciplinary Sessions:

Participate in engineering, design, electronics, and manufacturing sessions.

Industry Thought Leaders:

Hear from Julia Koerner and Altair’s leading technologists about the future of simulation and product design.

Hands-On Demos:

Watch real-world workflows and gain valuable insights into how these technologies transform industries.

Networking Opportunities:

Engage with like-minded professionals and experts to share insights and expand your network.

This event is an opportunity to be part of the global conversation about the future of design and innovation. Register now for the free virtual event on May 15th:

Designing the Future with Confidence

Simulation is not just a tool; it is a catalyst for innovation. With Altair’s advanced simulation solutions, teams can design smarter, iterate faster, and make more informed decisions early in development. As industries continue to embrace integrated simulation workflows, Altair remains at the forefront of this revolution, empowering engineers to overcome design barriers and accelerate time-to-market.

Join the global conversation at SSD 2025 and discover how Altair’s simulation tools can help your team create the products of tomorrow today.

References:

Altair, "Simulate at the Speed of Design 2025," Available: https://events.altair.com/simulate-at-the-speed-of-design-2025/.#

Altair, "Customer Story: Astra,"

Altair, "Customer Story: Mabe,"

Altair, "Altair - The Engineering Software Company," [Online]. Available: https://altair.com/

Parametric Architecture, “JK3D Designs Cactus Homes with Advanced Digital Fabrication,”