ROI at Lightning Speed: 3-Month Payback vs the Traditional 5-Year Wait in Injection Molding

When benchmarked against outsourcing, the desktop machine repays its USD15 k capital outlay in 3 months. The industrial press crosses break even at 5 years.

APSX‑PIM V3 vs. Industrial Injection Molding vs. Outsourcing

Executive Summary

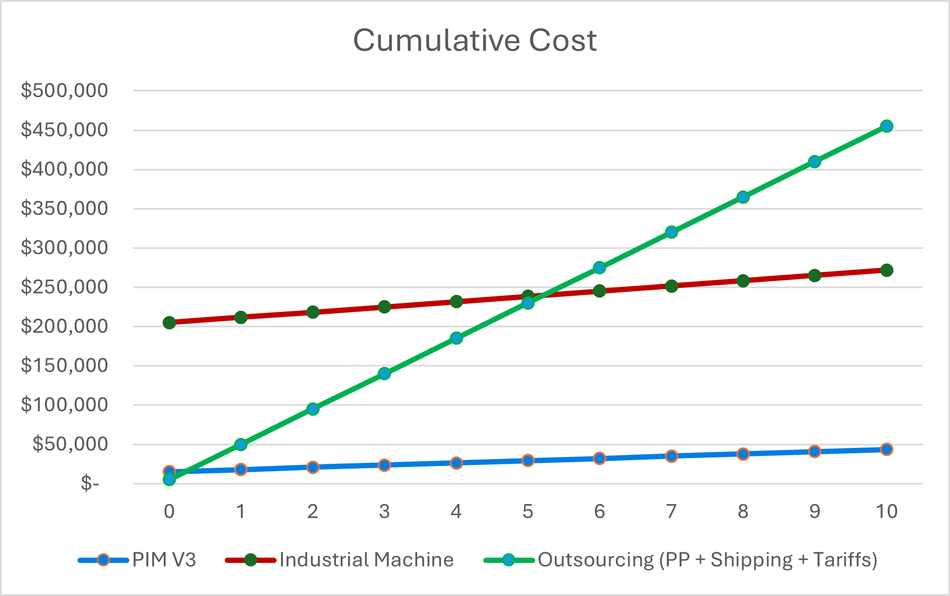

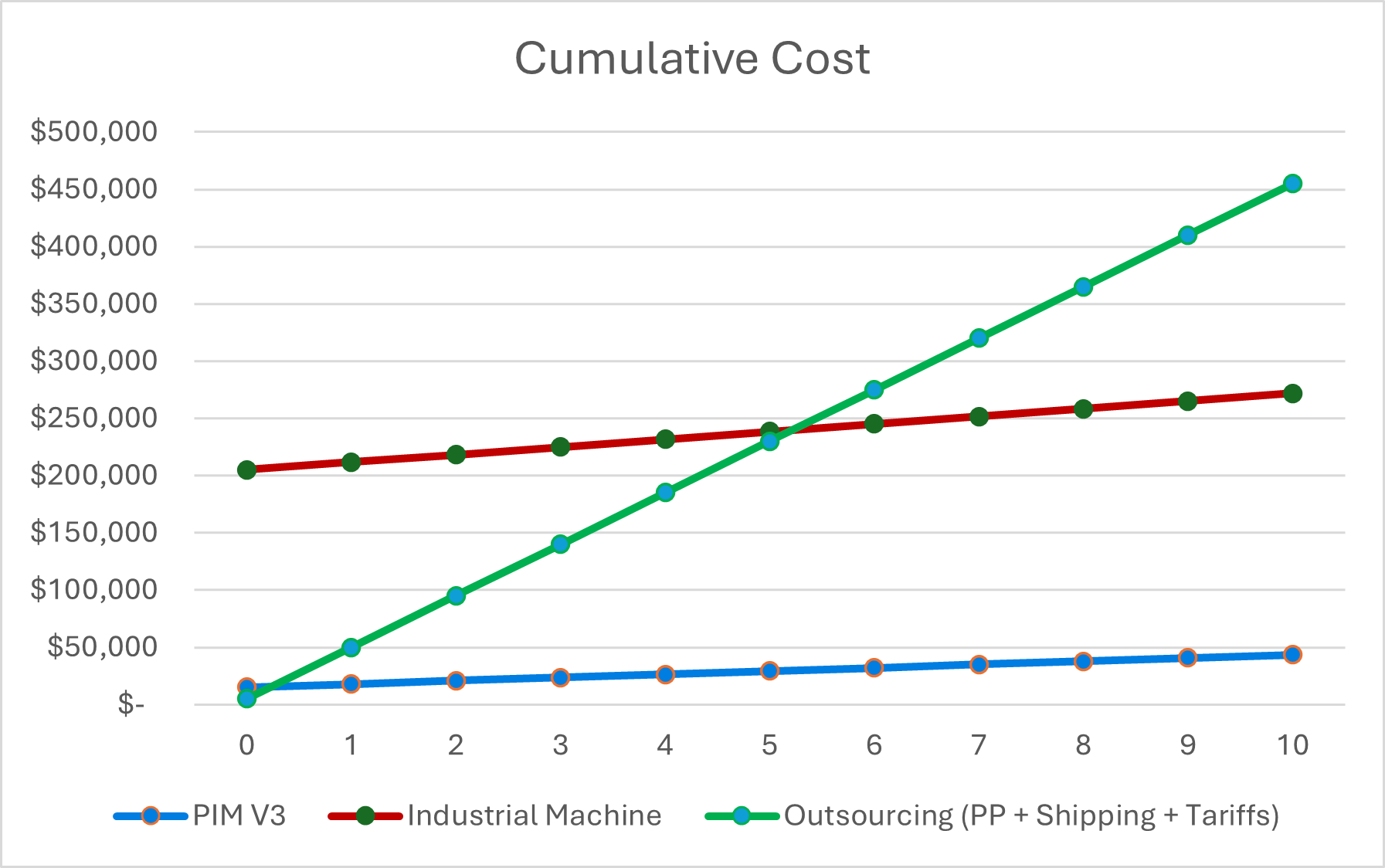

- Lowest total cost of ownership (TCO): APSX‑PIM V3 delivers a 10‑year cumulative cost of ≈ $43 k, versus $272 k for an industrial press and $455 k for outsourcing the same part.

- Fastest payback: When benchmarked against outsourcing, the desktop machine repays its $15 k capital outlay in ~3 months. The industrial press crosses break‑even at ≈ 5.2 years.

- Cost‑per‑part advantage: APSX‑PIM produces the 9 g PP part at $0.023 / pc, less than half the cost of an industrial cell ($0.053) and an order of magnitude below outsourcing.

- Ideal fit for SMEs & prototyping labs: Minimal floor‑space, 110 V plug‑and‑play power, and a sub‑$15 k ticket make the APSX‑PIM uniquely attractive where capital, footprint, or electricity capacity are constrained.

This white paper presents a comprehensive cost analysis and payback period comparison between the APSX-PIM injection molding machine and industrial alternatives. The analysis considers initial investment costs, operational expenses, and production capabilities to determine the total cost of ownership and potential return on investment. The outsourcing is presented as another alternative to compare.

Based on our analysis, the APSX-PIM demonstrates significant advantages in terms of initial investment and operational costs. With a purchase price of $13,500 compared to $200,000 for the industrial machines, the APSX-PIM requires substantially less capital investment. Additionally, the APSX-PIM's operational costs are dramatically lower, primarily due to reduced floor space requirements and energy consumption.

This analysis provides valuable insights for small to medium-sized manufacturers, prototyping operations, and businesses considering injection molding capabilities with limited capital resources.

Introduction

Background

Injection molding is the default process when tight tolerances, surface finish and repeatability matter. Historically, the six‑figure cap‑ex and large electrical service needed for industrial presses left start‑ups and pilot‑scale runs with a stark choice: outsource or forgo molding altogether. The APSX‑PIM desktop platform disrupts this paradigm by collapsing price, footprint and utility requirements—without sacrificing closed‑loop control or automatic cycling.

Purpose and Scope

This white paper aims to provide a detailed cost comparison between the APSX-PIM V3 desktop injection molding machine and the industrial alternatives. The analysis focuses on:

1. Initial investment costs

2. Operational expenses (electricity, labor, materials, facility requirements)

3. Production capabilities and efficiency

4. Total cost of ownership

5. Payback period analysis

The scope of this analysis is limited to the production of a specific part weighing 9 grams using polypropylene material, with an annual production volume of 125,000 parts. All calculations are based on current market prices and operational parameters provided by manufacturers and industry experts.

Methodology

The analysis employs a comprehensive cost modeling approach that accounts for:

- Capital expenditure (machine purchase and installation)

- Energy consumption (both heat-up and steady-state operation)

- Labor requirements

- Material costs

- Facility requirements (space, electrical)

- Production efficiency (cycle times, capacity)

All calculations were performed using consistent assumptions across all three machines to ensure a fair comparison.

All three scenarios—APSX‑PIM V3, a 100‑ton class industrial press, and outsourcing to a Chinese molder—were evaluated under identical production conditions:

- Part: 9 g polypropylene clip (single‑cavity)

- Annual volume: 125 000 pcs (≈ 500 pcs / shift, 250 shifts / yr)

- Scrap: 0 %

- Tooling: one‑cavity mold

Machine Specifications and Capabilities

Metric | APSX‑PIM V3 | Industrial Press |

Purchase price | $13,500 | $200,000 |

Installation cost | $0 | $5,000 |

Power (heat‑up / steady) | 0.27 kWh / 0.009 kWh | 3.0 kWh / 0.008 kWh |

Cycle time (9 g PP part) | 50 s | 20 s |

Floor space | 4 ft² | 400 ft² |

Electrical service | 120 V, 15 A | 400 V 3‑phase |

APSX-PIM V3

The APSX-PIM is a desktop injection molding machine designed for small-scale production and prototyping. Key specifications include:

- Purchase price: $13,500

- No installation costs

- Power consumption: 0.27 kWh during heat-up, 0.009 kWh at steady state

- Cycle time: 50 seconds per part

- Floor space requirement: 4 sq-ft

- Electrical requirements: Standard 110V outlet

- Production capacity: 72 parts per hour

Industrial Machine

The industrial injection molding machine represents a high-end, energy-efficient industrial solution. Key specifications include:

- Purchase price: $200,000

- Installation and mold cost: $5,000

- Power consumption: 3.0 kWh during heat-up, 0.008 kWh at steady state

- Cycle time: 20 seconds per part

- Floor space requirement: 400 sq-ft

- Electrical requirements: 400V 3-phase power

- Production capacity: 240 parts per hour

Outsourcing

The outsourcing to China option involves an initial mold cost. After that there is a piece price at $0.45 that includes production, shipping and tariffs:

Cost Analysis

Initial Investment

The initial investment represents the upfront capital required to purchase and install each machine:

PIM V3 | Industrial Machine | |

Purchase Price | $ 13,500 | $ 200,000 |

Installation | $ - | $ 5,000 |

Mold Cost | $ 1,500 | $ 1,500 |

Total Initial Investment | $ 15,000 | $ 206,500 |

The APSX-PIM requires significantly less initial investment - approximately 6.6% of the industrial machine cost. This dramatic difference in capital expenditure is a critical factor for businesses with limited financial resources.

Energy Costs

Energy consumption was analyzed in two phases: heat-up and steady-state operation. The analysis assumes 250 working days per year with one heat-up cycle per day:

PIM V3 | Industrial Machine | |

Heat-up Energy [kWh] | 0.27 | 3.00 |

Steady State [kWh] | 0.009 | 0.008 |

Annual Electric Cost/Yr | $ 143.10 | $ 211.50 |

While the industrial machine demonstrates superior energy efficiency during steady-state operation, the APSX-PIM's overall energy costs remain lower due to its significantly reduced heat-up energy requirements. The total annual electricity cost difference between machines is relatively minor compared to other operational expenses.

Labor Costs

Labor requirements were calculated based on 1 second of labor time per cycle at a rate of $25 per hour:

They are all the same labor cost per year: $862.50

Since the labor requirement per cycle is identical for all three machines, the annual labor cost is the same across all options. Although the industrial machines require highly skilled operators, this paper assumes that the operator skill level and hourly rate are consistent regardless of machine type.

Material Costs

Material costs were calculated based on a part weight of 9 grams using polypropylene at $1.60 per kg:

Material costs are identical ($1800/yr) across all three machines as they are producing the same part with the same material. This analysis does not account for potential differences in scrap rates or material efficiency between machines.

Facility Costs

Facility costs were calculated based on floor space requirements at an estimated rate of $9 per square foot per year:

PIM V3 | Industrial Machine | |

Floor Space [SF] | 4 | 400 |

Facility Cost/Yr | $ 36 | $ 3,600 |

The facility cost represents the most significant operational expense difference between the machines. The APSX-PIM's compact footprint results in dramatically lower space requirements, translating to substantial cost savings in facility expenses.

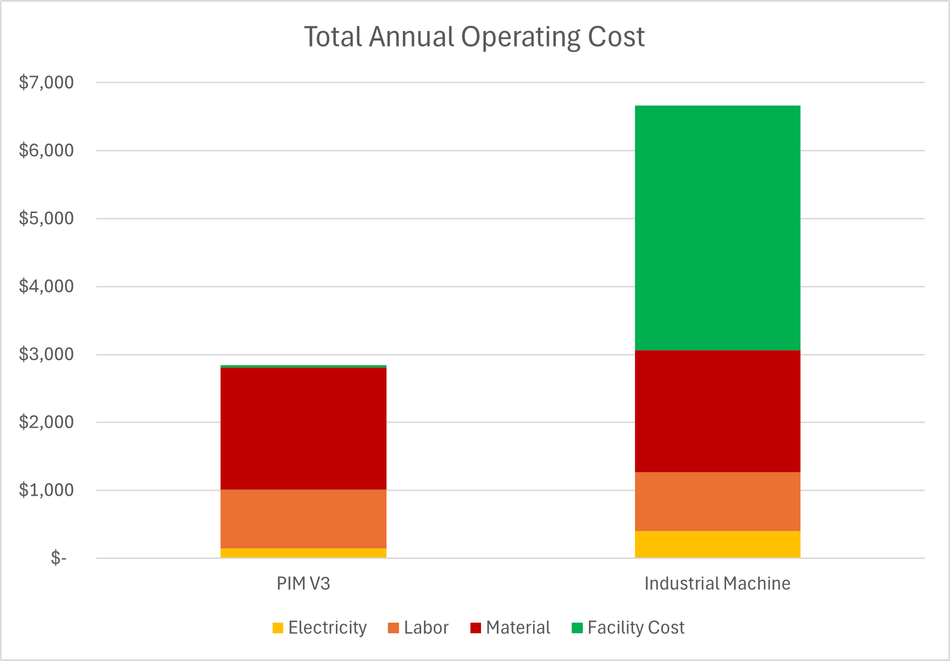

Total Annual Operating Costs

Combining all operational expenses provides the total annual cost for each machine:

PIM V3 | Industrial Machine | |

Electricity | $ 143 | $ 400 |

Labor | $ 868 | $ 868 |

Material | $ 1,800 | $ 1,800 |

Facility Cost/Yr | $ 36 | $ 3,600 |

Total Annual Cost | $ 2,847 | $ 6,668 |

Cost per part | $ 0.023 | $ 0.053 |

The APSX-PIM demonstrates a clear advantage in total annual operating costs, primarily driven by the dramatic difference in facility expenses.

The APSX-PIM produces parts at less than half of the cost of the industrial machine, representing a cost savings of $0.030 per part. For the annual production volume of 125,000 parts, this translates to annual savings of approximately $3,750 compared to the industrial machine.

Payback Period Analysis

The cumulative cost and the payback period analysis compares the additional initial investment required for industrial machines against potential operational cost savings. The initial machines cost includes the machine, the mold and the installation. The outsourcing has an initial mold cost then per piece cost:

Years in Operation | PIM V3 | Industrial Machine | Outsourcing (PP + Shipping + Tariffs) |

0 | $ 15,000 | $ 205,000 | $ 5,000 |

1 | $ 17,847 | $ 211,668 | $ 50,000 |

2 | $ 20,694 | $ 218,336 | $ 95,000 |

3 | $ 23,541 | $ 225,004 | $ 140,000 |

4 | $ 26,389 | $ 231,672 | $ 185,000 |

5 | $ 29,236 | $ 238,340 | $ 230,000 |

6 | $ 32,083 | $ 245,008 | $ 275,000 |

7 | $ 34,930 | $ 251,676 | $ 320,000 |

8 | $ 37,777 | $ 258,344 | $ 365,000 |

9 | $ 40,624 | $ 265,013 | $ 410,000 |

10 | $ 43,472 | $ 271,681 | $ 455,000 |

Since the industrial machines have higher initial investment and annual operating costs than the APSX-PIM, they do not even get close to APSX-PIM V3 cost level. Even increasing the number of cavities and sharing the machine with other part productions will not make it better for the industrial machine option.

Immediate payback vs outsourcing: APSX‑PIM overtakes the $5 k mold fee within the first 90 days of production. Industrial breakeven occurs at ≈ Year 5.2, after which it remains cheaper than outsourcing but never catches the desktop platform.

This represents cost savings over a decade of around $412,000 when choosing the APSX-PIM over the outsourcing, and $228,000 when choosing the APSX-PIM over the industrial machine.

Production Efficiency Considerations

While the cost analysis clearly favors the APSX-PIM, production efficiency must also be considered:

The industrial machines offer significantly faster cycle times, resulting in higher production rates. The industrial machine can produce the daily requirement of 500 parts in approximately 3 hours, compared to approximately 7 hours for the APSX-PIM.

For operations with limited production time availability or higher volume requirements, the faster cycle times of industrial machines may provide value.

Conclusion

The cost analysis presented in this white paper demonstrates that the APSX-PIM offers significant economic advantages over industrial injection molding machines and over the outsourcing for the production scenario analyzed. With an initial investment of just $15,000 compared to $205,000 for the industrial machines, the APSX-PIM requires substantially less capital expenditure.

The APSX-PIM also demonstrates dramatically lower operational costs, primarily due to reduced facility requirements. The total annual operating cost for the APSX-PIM is $2,847, compared to $6,668 for the industrial machines. This translates to a cost per part of $0.023 for the APSX-PIM versus $0.053 for industrial machines.

However, the decision between desktop and industrial injection molding machines should consider factors beyond direct costs, including production efficiency, part quality, material flexibility, and long-term scalability. The APSX-PIM represents an excellent solution for small to medium-sized manufacturers, prototyping operations, and businesses with limited capital resources, while industrial machines may still be justified for operations requiring higher production rates, superior process control, or advanced capabilities.

Recommendations

Based on the analysis presented in this white paper, we recommend:

1. **For small to medium-sized manufacturers**: The APSX-PIM offers a compelling economic advantage for annual production volumes around 125,000 cycles or less, particularly for operations with limited capital resources or facility space.

2. **For high-volume producers**: Industrial machines may be justified despite higher costs if production volumes significantly exceed those analyzed in this study or if production time availability is limited.

3. **For mixed production environments**: Consider a hybrid approach, using desktop machines like the APSX-PIM for lower-volume production and prototyping.

.

Visit www.apsx.com for more information.

Download the white paper as PDF below.